12Mm Ultra-White Glass With Printed White

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass:

We manufacture a wide range of glass to meet your different demands: Float glass, Tinted glass, Stained glass, Laminated glass, Mirror glass, Aluminum mirror, Silver mirror, Reflective glass, Online coated glass, Patterned glass, Figured glass, Wired glass, Colored glass, Tempered glass, Toughened glass, Safety glass, Shower doors glass, Emulsificated glass, Acid-etched glass, Obscure glass, Sandblasted glass, Solar glass, Ultra clear low iron glass, Low-E glass, Obscure glass, Glass block, Glass brick, Picture frame in different colors and sizes.

2.Main features of Glass:

1) Standard: CCC, intertek

2) 3 - 19mm float glass

3).Size: customized sizes available

4).tempered or silk

5).drill work available

6).Printing Furniture Glass ,Beautiful surface with good coverage.

Profiled glass, as your design and requirement

Type: clear, tinted, color glazed, coated, Low-E, IGU and laminated glass etc.

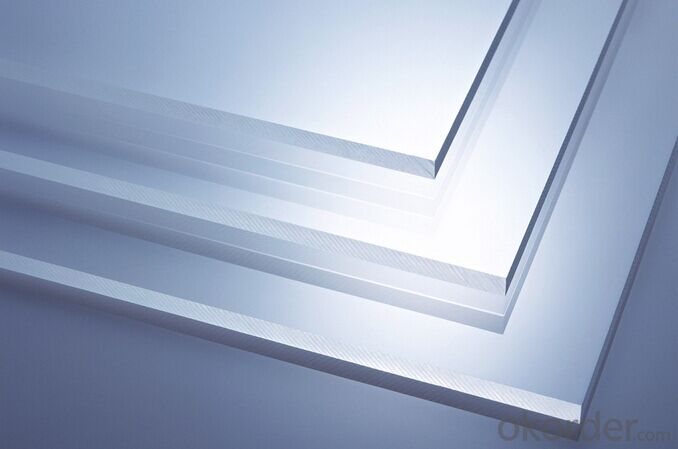

3.Glass Images:

4. Glass Technical Parameters:

CLEAR FLOAT GLASS

Thickness: 2mm-19mm

Sizes: 1524x2134mm, 1830x2440mm, 2140x3300mm, 2140x3660mm, 2250x3300mm, 3660x2140mm, 3660x2250mm etc.

EXTRA CLEAR GLASS

Thickness: 3mm-19mm

Sizes: 1830x2440mm, 2140x3300mm, 2140x3660, 2250x3300mm, 2250x3660mm etc.

TINTED GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Mist Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Ocean Blue, Pink etc.

Thickness: 3mm-12mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm, 2140x3660mm, 2250x3160mm etc.

REFLECTIVE GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Pink, Silver etc.

Thickness: 3mm-10mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm etc.

MIRROR

Types: Silver Mirror, Aluminum Mirror, Copper and Lead Free Mirror, Safety Mirror, Solar Mirror and Beveled Mirror etc.

Thickness: 1.5mm, 1.8mm, 2mm, 2.7mm, 3mm, 4mm, 5mm and 6mm etc.

Sizes: 1524x2134mm, 1830x1220mm, 1830x2440mm, 2140x3300mm, 2250x3300 etc.

LAMINATED GLASS

PVB Color: Clear, Green, Blue, Bronze, Grey, Milk white etc.

Glass Color: Clear, French Green, Dark Green, Ford Blue, Dark Blue, Bronze, Euro Grey etc. Float glass and reflective glass are available.

Thickness: 3+0.38+3mm, 4+0.38+4mm, 5+0.38+5mm, 6+0.38+6mm, 3+0.76+3mm, 4+0.76+4mm, 5+0.76+5mm, 6+0.76+6mm etc. till to 42.3mm

Sizes: 1830x2440mm, 2140x3300mm etc.

PATTERNED GLASS

Thickness: 3mm, 3.5mm, 4mm, 5mm, 6mm and 8mm

Sizes: 1220x1830mm, 1524x2134mm, 1830x2440mm, 3300x2140mm etc.

Patterns: Aqualite, Bamboo, Beehive, Chinchilla, Crystal, Diamond, Flora, Karatachi, Masterlite, Millennium, Mistlite, Morgon II, Moru, Nashiji, Rain and Wanji etc.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Chemical materials and additives needed for the production of glass

- The production process of float glass is introduced by taking ordinary production line of daily melting capacity of 600 tons in China as an example.Float glass is made in tin bath. The length of the whole production line is about 500 meters. It can produce 550 to 600 tons of glass every day. It is equivalent to 3 meters wide, 3 millimeters thick, and the glass belt is about 25 kilometers in length. Once started, 24 hours a day is uninterrupted until the furnace is stopped for about 8-10 years. Float production is the main mode of production of flat glass

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Glass: quartz, sodium carbonate, calcium carbonate paper: bark is enough.. cellulose + bleaching agent, such as activated carbon and other detergents, soap bar, sodium stearate

- Q: What is the raw material of glass products?

- Ordinary glass is the raw material of soda (sodium carbonate), limestone (calcium carbonate) and silica by high temperature reaction, with sodium silicate, calcium silicate and silica products, according to the needs of different substances will add color.For example, adding chromium oxide (Cr2O3) glass, is green; adding manganese dioxide (MnO2), purple glass; adding cobalt oxide (Co2O3) glass, blue glass, copper, copper oxide is high if the glass appeared blue and green; in order to lower the price of cuprous oxide (Cu2O) when there is red glass.Now, people use the oxide of rare earth elements as coloring agents to make all kinds of high-grade color glass. Colored glass doped with rare earth elements has a bright, bright color and even changes colors in different light. For example, in the glass of neodymium oxide has this characteristic, it shows purple red in the sunlight, in the fluorescence of purple blue, very beautiful. There is a kind of glass that changes with the intensity of light. People use it as the lens of glasses and the window glass of the house. With this kind of glass as a window, the room can maintain a certain brightness, and no longer need to use curtains to shade, so some people call it "automatic curtain"". It can prevent the UV rays of the sun through the library and Museum Library, installed on the glass, can protect the books and cultural relics from UV damage, in addition to the rare earths, directly adding tungsten and platinum in the glass, can also be made of glass.

- Q: What material is the simulation tree made of?

- The earliest to do simulation trees, rockery are used cement, the recent simulation tree and rockery, with a lot of resin. First, the resin simulation degree is extremely high, two is the cost and the cement cost approximately.

- Q: What is the difference between acrylic board, lotus board, organic board and PVC board?

- Organic boards are called organic plates, PS boards, PS organic boards, PS boards, light panels, light box boards, GPPS boards, benzene boards, color boards, etc. some places are simply called organic glass. People have different opinions. In fact, organic boards are different from organic glass.

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- Technological process:1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass;6, annealing: the molding of glass products into the annealing furnace annealing, balance the stress, to prevent self cracking.

- Q: What materials do we need to make glass septic tanks?

- Glass reinforced septic tanks require glass fiber and unsaturated polyester resin as the main raw materials:

- Q: The preparation process of glass and the basic material and the function of raw materials

- The main raw materials are: silica glass (sandstone), sodium carbonate, feldspar, dolomite, limestone and mirabilite.1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: liquid glass forming device with the corresponding sheet glass, bottles, glass, lamp, glass tube, a fluorescent screen......6, annealing: the molding of a variety of glass products into the annealing furnace annealing, balance stress, to prevent self cracking

- Q: What kind of material is the toughened glass film made of mobile phone?

- General crystalline silicon photovoltaic components using glass and backplane package structure, but there are amorphous silicon photovoltaic components using double glass package. So the glass itself is a piece, commonly known as ultra low iron tempered white suede (suede also wove, back also double glass structure with flat glass)

- Q: Why are most of the chemical instruments made from glass?

- Of course, the glass is colorless and transparent is also very important, the front of some people said that the glass is cheap, I would like to deny, in fact, this glass is not often in general glass, high temperature, the cost is much higher than that

Send your message to us

12Mm Ultra-White Glass With Printed White

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords