1145 H19 Aluminum Coil Foil for Controlled Atmosphere Brazing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Specifications of Aluminum Coil For Controlled Atmosphere Brazing

Alloy and Temper: 4004-O

Thickness: 0.20-3.0mm

Width: 16-1600mm

Advantage: we could divide the coil into narrow size according to customer’s request.

Package: seaworthy package.

2.Feature of Aluminum Coil For Controlled Atmosphere Brazing

steady and consistent quality, good product durability, high performance and cost ratio, professional team.

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

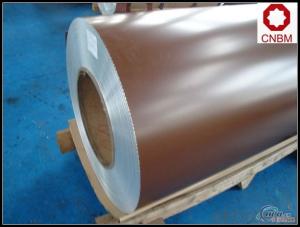

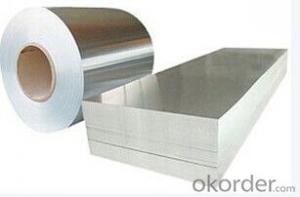

4. Image of Aluminum Coil For Controlled Atmosphere Brazing

5.FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

- Q: What is the role of aluminum coils in the construction of ships?

- Aluminum coils play a crucial role in the construction of ships, particularly in the marine industry. These coils are used to manufacture various components and structures that are essential for shipbuilding. One of the main advantages of using aluminum coils in ship construction is their lightweight nature. Aluminum is significantly lighter than traditional steel, which allows for increased fuel efficiency and better overall performance of the ship. This is particularly important for larger vessels, as reducing weight helps to minimize energy consumption and operating costs. Additionally, aluminum coils offer excellent corrosion resistance, making them ideal for the marine environment. Ships constantly face exposure to saltwater, which can be highly corrosive to metals. By using aluminum coils, shipbuilders can ensure that their vessels are better protected against rust and corrosion, ultimately increasing their lifespan and reducing maintenance requirements. Moreover, aluminum coils can be easily shaped and formed into various structures, offering greater design flexibility for shipbuilders. This versatility allows for the creation of complex and intricate ship components, such as hulls, superstructures, and bulkheads. Aluminum's excellent weldability also makes it easier to join different sections of the ship together, resulting in a more efficient and streamlined construction process. Furthermore, aluminum is a highly sustainable material. It is 100% recyclable, meaning that it can be reused without any loss in quality or performance. This makes aluminum coils an environmentally friendly choice for ship construction, aligning with the increasing emphasis on sustainability in the industry. In summary, the role of aluminum coils in ship construction is multifaceted. They provide lightweight, corrosion-resistant, and easily formable materials that contribute to improved fuel efficiency, durability, and design flexibility. Moreover, their recyclability makes them an environmentally conscious option. Overall, aluminum coils are a vital component in building ships that are efficient, durable, and sustainable.

- Q: How do aluminum coils contribute to sustainable transportation?

- Aluminum coils contribute to sustainable transportation by offering lightweight and corrosion-resistant properties, making them ideal for manufacturing various components in vehicles. By using aluminum coils, vehicles can be made lighter, resulting in improved fuel efficiency and reduced emissions. Additionally, the recyclability of aluminum ensures that it can be reused, reducing the need for virgin materials and minimizing environmental impact.

- Q: Just want to know for any boat builders out there. I have been told by my local paddling store that there are no aluminum kayaks. Why couldn't i build one? it cant be weight, I would build the frame from 1/2 inch square aluminum tubing and the body out of 1/32 high grade sheeting. So why does something like this not exist?

- There okorder

- Q: What industries utilize aluminum coils?

- There are several industries that utilize aluminum coils for various purposes. One of the major industries that extensively uses aluminum coils is the construction industry. Aluminum coils are commonly used for roofing, siding, and gutter systems due to their lightweight nature, durability, and resistance to corrosion. Additionally, the transportation industry also relies heavily on aluminum coils for manufacturing automotive parts, such as radiators, condensers, and heat exchangers, as aluminum is known for its excellent heat transfer properties. The packaging industry also utilizes aluminum coils for producing cans and containers due to their ability to preserve the freshness and quality of food and beverages. Moreover, the electrical industry relies on aluminum coils for manufacturing transformers, electrical conductors, and wiring, as aluminum is a good conductor of electricity. Lastly, the aerospace industry uses aluminum coils for constructing aircraft parts, such as wings, fuselage, and structural components, as aluminum provides strength while keeping the weight of the aircraft low.

- Q: Are aluminum coils suitable for architectural cladding?

- Architectural cladding can indeed utilize aluminum coils. Aluminum, a versatile and aesthetically pleasing material, is widely used in the construction industry due to its lightweight nature and durability. Aluminum coils can be easily shaped into various forms and sizes, making them perfect for architectural cladding applications. One of the notable advantages of using aluminum coils for cladding is their resistance to corrosion. Aluminum naturally develops a protective oxide layer, preventing rusting and deterioration over time. Consequently, aluminum proves to be a durable and low-maintenance option for architectural cladding. Moreover, aluminum coils offer a wide array of finishes and colors, providing greater design flexibility. Architects and designers can paint or coat them to match any architectural style or design concept, making aluminum coils a favored choice. Furthermore, aluminum is an environmentally friendly material. It is fully recyclable and has a significantly lower carbon footprint compared to cladding materials like steel or concrete. This makes aluminum coils a sustainable option for architectural projects. To sum up, aluminum coils are indeed suitable for architectural cladding due to their durability, corrosion resistance, design flexibility, and environmental benefits.

- Q: Can aluminum coils be used for seamless gutters?

- Yes, aluminum coils can be used for seamless gutters. Aluminum is a popular choice for gutter systems due to its durability, lightweight nature, and resistance to corrosion. Aluminum coils are commonly used to create seamless gutters, which offer several advantages over traditional sectional gutters. Seamless gutters are custom-made on-site, ensuring a perfect fit for the specific dimensions of the building. This eliminates the need for seams, which can be prone to leaks and require regular maintenance. Additionally, aluminum is easy to work with, allowing for seamless gutters to be formed into various shapes to accommodate the unique design of a building. Overall, aluminum coils are a practical and efficient option for creating seamless gutters.

- Q: What is the weight of an average aluminum coil?

- The weight of an average aluminum coil can vary depending on its dimensions and thickness. However, a typical aluminum coil can weigh anywhere between 1,000 to 10,000 pounds (450 to 4,500 kilograms).

- Q: What are the insulation options available for aluminum coils?

- There are various insulation options available for aluminum coils, including fiberglass insulation, foam insulation, and elastomeric insulation. These insulation materials help to improve the energy efficiency of the coils and prevent condensation or heat loss.

- Q: How are aluminum coils used in the production of food processing equipment?

- Aluminum coils are commonly used in the production of food processing equipment due to their excellent thermal conductivity, corrosion resistance, and lightweight nature. These coils are often formed into various shapes and sizes to create components like heat exchangers, evaporators, and condensers that help regulate temperature during food processing. Additionally, aluminum coils can be easily cleaned and sanitized, making them ideal for use in the food industry where hygiene is crucial.

- Q: This question asks for the distinctions between aluminum coil and steel coil, focusing on their properties and uses.

- <p>Aluminum coil and steel coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has good thermal conductivity, making it ideal for applications requiring flexibility and resistance to weathering. It's commonly used in construction, packaging, and electrical applications. Steel coil, on the other hand, is stronger and more durable, suitable for heavy-duty applications. It's often used in automotive, construction, and manufacturing due to its high strength and ability to withstand heavy loads. Steel is also magnetic, which is a property not shared by aluminum. The choice between aluminum and steel coil depends on the specific requirements of the project, such as weight, strength, and environmental resistance.</p>

Send your message to us

1145 H19 Aluminum Coil Foil for Controlled Atmosphere Brazing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords