1010 cold rolled steel with contact details

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 53737 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The raw material of cold rolled steel coil/sheet is high quality hot rolled product. Cold rolled steel coil/sheet as defined

in the EN 10130/98 standard, with guaranteed maximum mechanical characteristics and guaranteed minimum ductility

and formability.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal

for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their

chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

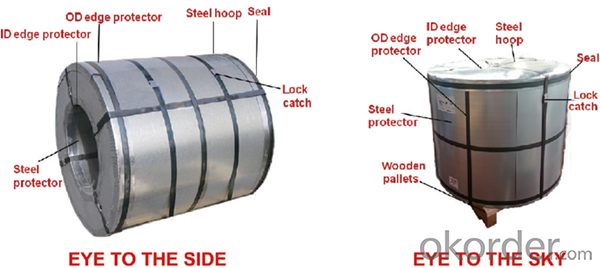

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as

soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What are the different types of steel coil grades and specifications?

- There are several different types of steel coil grades and specifications available in the market. These grades and specifications are designed to meet various industry requirements and applications. Some of the commonly used steel coil grades and specifications are: 1. Hot Rolled Steel Coils: These coils are produced by heating the steel above its recrystallization temperature and then rolling it at a high temperature. Hot rolled steel coils are commonly used in applications where dimensional accuracy and surface finish are not critical. 2. Cold Rolled Steel Coils: Cold rolled steel coils are produced by further processing hot rolled coils through cold reduction mills. This process results in improved surface finish, tighter tolerances, and higher strength compared to hot rolled coils. Cold rolled steel coils are widely used in automotive, construction, and electrical industries. 3. Galvanized Steel Coils: Galvanized steel coils are coated with a layer of zinc to protect them from corrosion. This process, known as galvanization, enhances the durability and longevity of the steel coils. Galvanized steel coils are commonly used in applications such as roofing, fencing, and automotive body parts. 4. Stainless Steel Coils: Stainless steel coils are made from a combination of iron, chromium, and other elements that provide excellent corrosion resistance and high strength. These coils are widely used in industries such as food processing, chemical, and medical, where hygiene and corrosion resistance are critical. 5. High-strength Low-alloy (HSLA) Steel Coils: HSLA steel coils are designed to have higher strength and improved formability compared to conventional carbon steels. These coils are commonly used in structural and transportation applications, where weight reduction and high strength are required. 6. Electrical Steel Coils: Electrical steel coils, also known as silicon steel or transformer steel, are specifically designed for use in electrical equipment such as transformers, motors, and generators. These coils have low core losses and high magnetic permeability, making them ideal for efficient energy transfer. 7. Tool Steel Coils: Tool steel coils are specially formulated to have high hardness, wear resistance, and toughness. These coils are commonly used in the manufacturing of cutting tools, dies, and molds. These are just a few examples of the various types of steel coil grades and specifications available in the market. The selection of the appropriate grade and specification depends on the specific application requirements, such as strength, corrosion resistance, formability, and surface finish.

- Q: How much do steel coils weigh?

- The weight of steel coils is subject to variation, which is determined by multiple factors including coil thickness, width, length, and the particular type of steel employed. In general, steel coils can range in weight from a few hundred pounds to several tons. It should be emphasized that the measurement of steel coils typically revolves around their weight per unit area, referred to as the "basis weight" or "coil weight".

- Q: What are the dimensions of steel coils used in the transportation equipment industry?

- The dimensions of steel coils used in the transportation equipment industry can vary depending on the specific requirements and applications. However, there are some common dimensions that are widely used. The width of steel coils used in the transportation equipment industry typically ranges from 600mm to 2000mm (24 to 78 inches). This width is chosen to ensure compatibility with the machinery and equipment used for transportation, such as trucks, trailers, and railcars. The thickness of steel coils can vary greatly depending on the specific application and the desired strength of the material. However, common thickness ranges for transportation equipment industry steel coils are typically between 0.5mm and 6mm (0.02 to 0.24 inches). The inner diameter of steel coils used in the transportation equipment industry is typically standardized at either 508mm (20 inches) or 610mm (24 inches). This standardization allows for easy handling and compatibility with the machinery used in the industry. The outer diameter of steel coils can vary depending on the width and thickness of the coil. However, common outer diameter ranges for transportation equipment industry steel coils are typically between 1000mm and 2200mm (39 to 87 inches). It is important to note that these dimensions are not fixed and can be customized based on specific requirements and applications within the transportation equipment industry.

- Q: What are the different methods of cut-to-length shearing for steel coils?

- Steel coils can be cut-to-length using various methods, each with unique advantages and applications. Some commonly used methods include: 1. Rotary Shearing: This technique utilizes a rotating shear blade to cut through the coil. It offers excellent precision and can handle a wide range of material thicknesses. Rotary shearing is well-suited for high-volume production and allows for high cutting speeds. 2. Guillotine Shearing: In this method, a straight blade is employed to cut through the coil. It is a versatile technique that can handle different material thicknesses and widths. Guillotine shearing is relatively simple and efficient, making it a popular choice for many applications. 3. Slitting: Slitting involves creating multiple longitudinal cuts in the coil to produce narrower strips. It is commonly used when a coil needs to be divided into smaller coils or when narrower strips are necessary for specific applications. Slitting can be performed using either rotary or straight blades. 4. Laser Cutting: Laser cutting employs a high-powered laser beam to melt or vaporize the material, resulting in a precise and clean cut. It is ideal for cutting complex shapes or patterns and can handle both thin and thick steel coils. Laser cutting offers high accuracy and minimal material distortion. 5. Waterjet Cutting: In this method, a high-pressure stream of water mixed with abrasive particles is used to cut through the coil. It is suitable for a wide range of materials, including steel, and can achieve high accuracy. Waterjet cutting is often utilized for cutting thick coils or when minimizing heat-affected zones is crucial. Each method has its own strengths and limitations, and the selection depends on factors such as material thickness, required precision, production volume, and specific application requirements. Choosing the most suitable method is vital to ensure efficient and high-quality cut-to-length shearing for steel coils.

- Q: Steel Strings on your guitar or nylons? Why?

- There is no OR about it. You CANNOT use steel strings on a nylon string guitar because the increased tension will actually warp the top of the guitar and eventually pull the bridge right off! (I have seen it happen several times!) Although it is possible to put nylon strings on a steel string guitar it is not recommended. Nylon strings do not have as much tension as a steel string guitar is designed for. Steel string guitar necks are actually designed with a bit of back bow to compensate for the high tension of steel strings. Nylon strings have a much lower tension which could cause the neck of a steel string to settle slightly, which could actually cause the strings to fret out. It is not common, but it does happen. So keep your guitars happy and only string them with the proper strings.

- Q: I know there is soft steel and sturdier steel they use in products. The sturdier often used for equipment that requires more durability when in operation.

- Some steel won't 'harden' very much to begin with. Mild steel found commonly around the shop/farm/house has few alloys other than carbon, and may not get the desired hardness no matter what you do. A quick test to see what type you have (mild steel vs. alloy) is to touch it to a grinding wheel.

- Q: What are the different methods of slitting edge trimming for steel coils?

- Steel coils can be slit using various methods, each with its own benefits and applications. 1. Rotary Shear Slitting: This approach utilizes rotary knives mounted on a rotating shaft to cut through the steel coil. The knives create a shearing action as they pass through the coil. Rotary shear slitting is versatile, accommodating various coil thicknesses and materials. It is commonly employed for high-volume production, offering clean and precise cuts. 2. Crush Cut Slitting: This method involves pressing the steel coil against a hardened anvil with a rotating knife. The coil is cut by crushing it against the anvil. Crush cut slitting is suitable for thinner gauge materials and those sensitive to shearing forces. It provides clean cuts but may have limitations in terms of coil thickness and width. 3. Razor Slitting: Razor slitting employs a razor blade mounted on a rotating shaft to slice through the steel coil. This method is commonly used for thin and delicate materials that require precise and burr-free edges. While it provides clean cuts, it may be limited in terms of coil thickness and width. 4. Shear Slitting: This approach utilizes a pair of opposing blades to shear through the steel coil. The blades move past each other, creating a scissor-like cutting action. Shear slitting is commonly used for heavier gauge materials, offering clean and precise cuts. It is suitable for high-speed production and can handle a wide range of coil thicknesses and materials. 5. Laser Slitting: Laser slitting employs a high-powered laser beam guided by computer-controlled optics to cut through the steel coil. It offers precise and clean cuts and is suitable for various coil thicknesses and materials, including high-strength steels. Laser slitting provides a high level of accuracy and can handle complex cutting patterns. Each method has its own advantages and considerations, depending on the specific requirements of the steel coil slitting operation. Factors such as coil thickness, material type, desired edge quality, and production volume will influence the choice of slitting method.

- Q: Does aluminum or steel hold up better? We found a steel for 1/2 the price of aluminum, obviously its heavier but any other downsides? rust faster ect? also, does anybody know, in PA do you pay sales tax on trailers? and do dealers normally give you license plates to get the trailer home with? we live 3 hours away from the dealer so thats why i want all details :) would stink if i messed up!!

- I bought a steel trailer. It was much heavier than the aluminum, as you said. But really, they are equivalents. As long as you have enough power to haul the trailer, you can use steel. We never had a rust problem with ours. In PA you do pay sales tax on horse trailers, stock trailers, etc. I forget about the plates, though. It's been a few years since we got our trailer. I would assume they would give you something to get the trailer home with though.

- Q: What are the common maintenance practices for steel coils?

- Common maintenance practices for steel coils include regular cleaning to remove dirt, debris, and moisture, applying protective coatings to prevent corrosion, proper storage to avoid damage and contamination, and periodic inspections for any signs of damage or wear. Additionally, proper handling and transportation practices should be followed to prevent bending or crushing of the coils.

- Q: What are the different types of steel coil edge treatments?

- There are several different types of steel coil edge treatments used in the manufacturing and processing of steel coils. These treatments are done to enhance the edge quality, protect against damage, and facilitate handling and processing of the coils. Some of the common types of steel coil edge treatments include: 1. Mill Edge: This is the standard edge treatment provided by the steel mill. It is the raw edge of the steel coil that has been produced during the hot rolling process. Mill edge is typically sharp and may have some irregularities. 2. Slit Edge: Slit edge is a type of edge treatment where the coil is slit to the desired width, and the edges are then processed to remove any burrs or unevenness. Slit edge coils have smoother edges compared to mill edge coils. 3. Deburred Edge: Deburring is a process that removes any sharp or rough edges from the coil. It is done using specialized equipment or techniques to create a smoother and safer edge. Deburred edges are commonly used in applications where safety and handling are critical. 4. Rounded Edge: Rounded edge treatment involves rounding the edges of the coil to reduce the risk of damage during handling and processing. This treatment is often used in applications where the coil needs to be uncoiled or fed into machinery without causing any damage. 5. Beveled Edge: Beveling is a process where the edges of the coil are chamfered or cut at an angle. Beveled edges are used in applications where easy insertion, joining, or welding of the coil is required. The beveling process also helps to improve the strength and durability of the edge. 6. Sheared Edge: Shearing is a cutting process where the coil is cut to the desired width using high-pressure blades or scissors. Sheared edge treatment provides a clean and straight edge, free from burrs or irregularities. It is commonly used in applications where precise dimensions and a smooth edge are required. These are just a few of the different types of steel coil edge treatments commonly used in the industry. The choice of edge treatment depends on the specific requirements of the application, such as handling, processing, safety, and aesthetics.

Send your message to us

1010 cold rolled steel with contact details

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 53737 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords