10% Ash Foundry Coke in size 80-120mm in Shandong

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.9

- Supply Capability:

- 1009 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

Foundry Coke is the main fuel of melting iron in the oven. It can melt the materials in the over, make the iron reach great heat, and keep good air permeability by sustain stock column. Thus, the foundry coke should have the characteristics of big block, low reactivity, small porocity, enough anti-crush strengh, low ash and low sulphur.

The coke handled by our cooperation is made from superior coking coal of Shanxi province. Provided with the advantages of low ash, low sulphur and high carbon. Our coke is well sold in European, American, Japanese and South-east Asian markets. Our owned Coke plant are located in Shanxi Province and supplying of you many kinds of coke.

we supply Foundry Coke long-term, its characteristic is best strength, low sulfur and phosphorus,thermal stability.

Specifications:

ASH % | 8% max | 10% max | 12% max |

V.M.% MAX | 1.5% max | 1.5% max | 2% max |

SULFUR % | 0.65% max | 0.65% max | 0.7% max |

MOISTURE | 5% max | 5% max | 5% max |

Size | 80mm-120mm,80-150,100-150mm, or as request | ||

Features

1. Our quality is always quite good and stable which is producing and packing according to customers' requirements.

2. Putting Client profile into first, achieved mutual benefit.

3. Good partner on business. It's a good and wise choice for customers' to purchase from us. It's our great honor to cooperate with you.

4. We can supply documents as follows:

- bill of loading,

-Invoice,

-Packing List

-Insurance

We will provide better service

-standard inspection pictures of the container as specified by INSPECTORATE

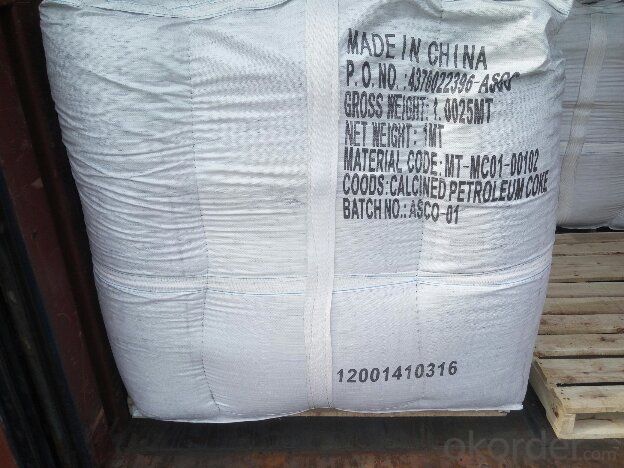

Pictures

FAQ

1. What is the packing?

In 25kg bag/ In jumbo bags without pallet/ Two jumbo bags with one pallet/ or as customers’ request

2. What is the production capacity?

10 thousand tons per month

3 What is payment term?

Irrevocable LC at sight/ 20% down payment by T/T and 80% against BL copy byT/T/ or to be discussed

4 What is the service?

We will send sample to the third party(CIQ, CCIC, SGS,BV or to be discussed) for checking, and present the test certificate and loading repot of shipment.

- Q: Will long-term use of carbon alloy chopsticks cause cancer?

- Do chopsticks also cause cancer? Experts say, should not use too long, 3 to 6 months that change, pay attention to chopsticks material selection, use and maintenance. Have you noticed how often the chopsticks are changed at home? Recently, a news about the need for regular replacement of chopsticks, attracted the attention of Internet users. According to reports, hidden in the small groove in the chopsticks bacteria, may cause dysentery, gastroenteritis and other diseases, it is recommended that the public, chopsticks should be replaced at regular intervals of 3~6 months. This makes many people surprised, "used so many years chopsticks, do not know!"." Yesterday morning, in the south near Xi'an Renrenle supermarket shopping public Ms. Hao said. Subsequently, a random survey of 20 members of the public, of which 4 people said that in the six months of internal moving or kitchen renovation and replaced chopsticks. While the other 16 citizens, the number of chopsticks used in the home was 1~3 years. Especially for families with old people, chopsticks are updated more slowly. "The old man can't bear to throw it. He can't help it. Every time he comes to the restaurant, the chopsticks are not enough."." Liu said the public. In this regard, yesterday, director of the Xi'an Municipal Hospital of traditional Chinese Medicine Department of Gastroenterology physician Huang Yahui said, if the wood and bamboo chopsticks used for a long time, it is easy to breed bacteria sawdust loose.

- Q: Often see a lot of cars made of carbon fiber body, is this material flammable?

- No, it's not flammable. You can't burn it.Pre oxidized excess oxygen filaments cannot be burned.

- Q: What is the carbon content of different types of household waste?

- The carbon content of different types of household waste can vary significantly. Generally, organic waste such as food scraps, yard trimmings, and paper products have high carbon content, while non-organic waste like plastics and metals have low or no carbon content.

- Q: How does carbon impact the ozone layer?

- The ozone layer is not directly affected by carbon, but carbon-containing compounds such as CFCs can greatly impact it. When CFCs are released into the atmosphere, they can reach the stratosphere and break down due to UV radiation, releasing chlorine atoms. These chlorine atoms then destroy ozone molecules catalytically, causing the depletion of the ozone layer. The depletion of the ozone layer is a crucial environmental concern because it allows more harmful UV radiation from the sun to reach the Earth's surface. Increased UV radiation can have negative effects on human health, including skin cancer, cataracts, and weakened immune systems. It can also harm ecosystems by damaging phytoplankton, which are vital to the marine food chain, and affecting the growth of plants and crops. To address this issue, the international community has taken measures to decrease the production and usage of substances that deplete the ozone layer, including CFCs. The Montreal Protocol, an international environmental agreement, has successfully phased out the production of CFCs and other harmful substances. This has contributed to the recovery of the ozone layer, although it remains a long-term process. In conclusion, carbon itself does not directly impact the ozone layer. However, carbon-containing compounds like CFCs, when released into the atmosphere, can cause the destruction of the ozone layer. Efforts to reduce the production and usage of these substances that deplete the ozone layer have been essential in safeguarding the ozone layer and mitigating the harmful effects of increased UV radiation.

- Q: Last night to go to the supermarket to buy 5 batteries, see Toshiba carbon batteries, I finally bought the super alkaline batteries, alkaline batteries and carbon is the difference in where? What kind of battery is best for digital cameras? Thank you

- Because the ingredients still contain cadmium, and therefore must be recovered, so as to avoid damage to the environment of the earth.Alkaline batteries are suitable for large power consumption and long time use. The internal resistance of the battery is low, resulting in the current general Zn Mn batteries, is conductive copper, steel shell shell is safe and reliable. No need to recycle. Based on his environmental protection, and the current characteristics of large, so now alkaline battery more.

- Q: What are the impacts of carbon emissions on the stability of grasslands?

- The stability of grasslands is significantly affected by carbon emissions. When carbon dioxide (CO2) is released into the atmosphere, it contributes to the greenhouse effect and causes global warming. This rise in temperature has various harmful consequences for grasslands. To begin with, higher temperatures can disrupt the equilibrium of grassland ecosystems. Many grassland species require specific temperatures for their growth and reproduction. As temperatures increase, these species may struggle to adapt, resulting in a decline in their populations. This disruption can negatively impact the overall biodiversity and ecological stability of grasslands. Additionally, global warming can change precipitation patterns, leading to alterations in water availability in grasslands. Reduced rainfall or increased evaporation can create drought conditions, making it challenging for grasses to flourish. This can ultimately cause grasslands to transform into barren areas devoid of plant life, a process known as desertification. Moreover, carbon emissions contribute to the acidification of the oceans, which indirectly affects grasslands. Acidic ocean waters impact marine organisms, including those responsible for generating nutrients that are carried by winds to coastal and inland grasslands. If these nutrient sources decline, grasslands may experience reduced fertility and productivity, ultimately affecting the stability of these ecosystems. Lastly, carbon emissions can worsen the frequency and intensity of wildfires. Grasslands are naturally adapted to periodic fires, which play a vital role in maintaining biodiversity and regulating plant populations. However, the increase in carbon dioxide levels can fuel more severe and frequent wildfires, leading to the destruction of grasslands and making their recovery more challenging. In conclusion, carbon emissions have numerous negative impacts on grassland stability. They disrupt the balance of grassland ecosystems, change precipitation patterns, contribute to ocean acidification, and increase the risk of wildfires. These effects can result in biodiversity loss, desertification, reduced fertility, and overall instability in grassland ecosystems. It is essential to reduce carbon emissions and mitigate the consequences of global warming to ensure the long-term stability and preservation of grasslands.

- Q: What are the different methods of measuring carbon dioxide levels in the atmosphere?

- There exist various techniques for assessing carbon dioxide levels in the atmosphere. These techniques encompass direct measurement, remote sensing, and ice core analysis. Direct measurement stands as the most precise and extensively employed approach. It encompasses collecting air samples from numerous locations worldwide and analyzing them using gas analyzers. These analyzers possess the capability to gauge the concentration of carbon dioxide in the air, typically expressed in parts per million (ppm). Remote sensing represents an alternative method for measuring carbon dioxide levels. It involves the utilization of satellite-based instruments to observe and quantify the quantity of carbon dioxide present in the Earth's atmosphere. These instruments can detect the absorption and scattering of sunlight caused by carbon dioxide molecules, thereby rendering valuable data concerning its concentration. Ice core analysis constitutes a historical technique for assessing carbon dioxide levels. Scientists delve deep into polar ice sheets and procure ice cores. These ice cores harbor trapped air bubbles from hundreds or even thousands of years ago. By analyzing the carbon dioxide content within these bubbles, scientists can recreate past atmospheric carbon dioxide levels and juxtapose them with contemporary levels. Each of these methods possesses its own merits and limitations. Direct measurement furnishes real-time data and precise measurements, albeit necessitating an extensive network of monitoring stations worldwide. Remote sensing offers a global perspective and the ability to cover large areas, yet it may struggle to resolve fine-scale spatial variations. Ice core analysis delivers valuable long-term historical data, but its applicability is confined to specific regions and solely permits indirect measurements. The amalgamation of these techniques empowers scientists to obtain a comprehensive comprehension of carbon dioxide levels in the atmosphere, aiding in the monitoring and evaluation of the impact of human activities on climate change.

- Q: How to match?Want to breed a batch of roses seedlings, but the seedbed of mud, carbon soil do not know how to get, there is help in this regard...

- Five: sowing, that is, sowing and breeding in spring. Can also be seeding and furrow sowing, usually in mid April to germination. Spring planting and transplanting time autumn planting two, usually in late autumn or early spring before the leaves after the sap flow. Grafting grafting used multiflora rootstock, grafting and grafting of two points. Autumn budding survival rate, grafting position close to the ground as far as possible, the specific method is: in the side branch with rootstock grafting knife on the skin do "T" shaped incision, and then rose from the year growth of branches in a good selection of bud. Insert the bud into the "T" incision, then tie it with a plastic bag and shade properly so that it will heal in about two weeks. Plant ramets breeding more in late autumn or early spring, is the whole rose out of ramets soil, each plant has 1 to 2 branches and with some fibrous roots, the colonization in the basin or open, then can blossom. Cutting method in late autumn or early spring rose dormancy, their mature with 3 to 4 shoots cuttings. If the shoots are cut, shade properly and keep the seedbed moist. After cutting, the root can take root in 30 days, and the survival rate is from 70% to 80%. If the cuttings are dipped in the root, the survival rate will be higher. Layerage general in the summer, is the rose from parent branches bent down and pressed into soil, buried in the central branches, the lower half circle of the bark off, exposing branch end, the branches grow adventitious roots and grow new leaves, and then cut off the mother. As for the preparation of nutritious peat soil according to the following formula: two (1) mixture of peat mire soil and vermiculite, the proportion (by dry weight) for each 1/2 or 3/5:1/4; 2/5 or 3/4:1/4, then add the right amount of limestone (dolomite) and sandy fertilizer. (2) peat swamp soil 25-50%, vermiculite 0-25%, plus 50% of the soil. All of the above materials have been bought in the flower market.

- Q: The main difference between steel and iron is the difference in carbon content

- The carbon content of 2% ~ 4.3% said that the iron carbon alloy cast iron. Iron is hard and brittle, but the pressure to wear. According to the existing steel carbon iron in different forms can be divided into white iron, gray iron and ductile iron. White cast iron with Fe3C carbon distribution, fracture is silver white, hard and brittle, not in mechanical processing, steel raw materials, it is also called the carbon graphite iron for steelmaking. The distribution of gray, gray fracture, easy cutting, easy casting, wear. If the carbon distribution is said to spheroidal graphite nodular cast iron, its mechanical properties and processing performance is close to steel special alloy elements added. In the cast iron can be special cast iron, such as adding Cr, the wear resistance can be greatly improved, with important applications in special conditions

- Q: What are the different types of carbon-based composites?

- There are several different types of carbon-based composites, including carbon fiber reinforced polymers (CFRP), carbon nanotube composites, carbon nanofiber composites, and graphene composites.

Send your message to us

10% Ash Foundry Coke in size 80-120mm in Shandong

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.9

- Supply Capability:

- 1009 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches