1.5mm liner price hdpe black rolls geomembrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of 1.5mm liner price hdpe black rolls geomembrane:

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Main Features of 1.5mm liner price hdpe black rolls geomembrane:

1.Long life, anti-aging, roof material can be more than 20 years, underground can be more than 50 years.

2. Good tensile strength, high elongation.

3. Good high/low temperature flexibility

4.Easy to construct, no pollution.

5. Good anti-corrosive ability, can be used in special area

6.Various colors are available

Specifications of 1.5mm liner price hdpe black rolls geomembrane:

No. | Item | 1.5mm liner price hdpe black rolls geomembrane | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

Applications of 1.5mm liner price hdpe black rolls geomembrane:

1,Prevent leakage disposal in waste burying field or waste water or waste dregs disposing field

2,River bank, lake dam, mine remaining, reservior, tunnel, liquid storage pool (pit, mine)

3,Preventing leakage in subway, basement, tunnel, hole

4,Anti-solt leakage in roadbed and other groundsill

5,The plane direction laying of dam, the vertical direction laying for groundsill, used in the construction fence and waste material field

6,Used in seawater or freshwater feed field

7,Used in groundsill of road , highway, railway and waterproof layer of swelling clay and wet collapsed loess

8,Preventing leakage on rooftop

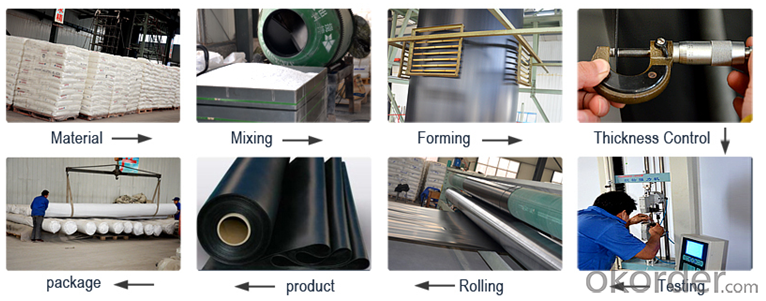

IMages of 1.5mm liner price hdpe black rolls geomembrane:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can geomembranes be used for lining tunnels?

- Yes, geomembranes can be used for lining tunnels. Geomembranes are impermeable sheets made of synthetic materials that are designed to provide a barrier against water, chemicals, and other substances. They are commonly used for various applications in civil engineering, including tunnel lining. Geomembranes can help prevent water infiltration, soil erosion, and the migration of harmful materials, providing structural integrity and environmental protection to tunnels.

- Q: Can geomembranes be used in pond and lake liners for public parks and recreational areas?

- Yes, geomembranes can be used in pond and lake liners for public parks and recreational areas. Geomembranes are durable, impermeable liners that can effectively prevent water seepage and contamination, making them ideal for maintaining the water quality in ponds and lakes. Additionally, they are customizable and can be tailored to fit various shapes and sizes, making them suitable for different recreational areas.

- Q: How do geomembranes perform in high groundwater table areas?

- Geomembranes perform well in high groundwater table areas as they act as an impermeable barrier, preventing water from seeping through and causing potential damage. This helps in maintaining the integrity of structures and controlling water flow, making them an effective solution in such conditions.

- Q: Geomembrane seams inspection should use aerate inspection method, what's the length that inspection demands? is there any national standard?

- it's regarded as qualified connection, such as the gas inside the seams leaks along with the gas needle, when examined with microscope ; detecting distance of each section should be about 1.0m, clamping the gas needle, input the air, if there are bubble leaks but without gas leaking, 5m-3, you can use welding gun or adhesive to deal. 5-2Mpa, you can use figer to press gas needle and see whether two seams are flat. 2, the pressure on the testing procedures of geosynthetics should be controled in 0. while pumping, "geosynthetics technical specifications" GB50290-98 geomembrane seam site, there is currently no good methods & # 57350, then a pump with a pressure gage, and a melting point or seams foam edge, etc. time is in about 30s, the gas needle wil pass through a hole between the seams. & # 57350, dotted, after observing more than 30 seconds, put the microscope on the suspicious place; mostly visual & # 57350 under normal circumstances, welding two seams between the torch with welding gun. 1, no wrinkle, no slag, transparent, plug the needle hole with plasticine.

- Q: how to use the wall poster transfer membrane?

- The following is the answer for the question how to use the wall poster transfer membrane inquire tearing down directly and pasted it. instant paste is also called self-adhesion label material, it is a composite material which use the paper and the membrane or special material as the surface material, the back coated with the adhesive and the silicon coated as the protective paper as the bottom paper. instant paste is also called self-adhesion label material, it is a composite material which use the paper and the membrane or special material as the surface material, the back coated with the adhesive and the silicon coated as the protective paper as the bottom paper. Due to there are a variety of coating techniques, resulting in sticky material formed with different grades, the current direction of development from the traditional roll coating, blade coating to the high pressure casting coating direction development in order to ensure maximum uniform coating sensual, avoid generating bubbles and pinholes, coating quality assurance,

- Q: What determines the hardness of paint film

- it is one of the important properties of machinery strength of paint film. Its physical meaning can be understood as the resistance of the film surface to the action of the other hardness of the larger objects. It can be determined by measuring the ability of the film to resist deformation when a certain mass load is exposed on the surface of the film, (including the ability of deformation caused by collision, indentation or scratching). the test equipment should have damped pendulum hardness, scratch hardness, indentation hardness ,ect..

- Q: How do geomembranes withstand environmental stressors?

- Geomembranes are designed to withstand environmental stressors through their unique physical and chemical properties. They are made of durable materials, such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC), which offer excellent resistance to UV radiation, chemical attack, and mechanical stresses. Additionally, geomembranes are often reinforced with additives or textiles to enhance their strength and puncture resistance. These properties enable geomembranes to effectively protect against environmental stressors such as temperature fluctuations, moisture, chemical exposure, and physical impacts, ensuring their long-term performance and durability.

- Q: How do geomembranes handle ground freezing?

- Geomembranes are designed to handle ground freezing by providing a barrier that prevents the movement of water and the formation of ice within the soil. They act as a protective layer that prevents the freezing ground from exerting pressure on underlying structures, preventing potential damage. Additionally, geomembranes can be installed with insulating materials to further mitigate the effects of ground freezing. Overall, geomembranes are an effective solution to manage the challenges posed by ground freezing.

- Q: in what areas does geomembrane usually apply? Please recommend cost-effective geomembrane.

- Clean water such as reservoir, and the pool also uses flexible impermeable geomembrane which is a typical representative of the flexible seepage proof material. seepage-proof geomembrane is preferable to a large area needs leakage pollution prevention like residue field. Cost-effective. The advantage is to prevent liquid leakage, mining waste water, sewage, petrochemical wastewater.

- Q: Can geomembranes be used in decorative ponds and water features?

- Yes, geomembranes can be used in decorative ponds and water features. They are commonly used as liners to prevent water seepage and maintain the desired water level. Geomembranes provide an effective barrier, ensuring the pond or water feature remains leak-proof and aesthetically pleasing.

Send your message to us

1.5mm liner price hdpe black rolls geomembrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords