1.5mm Black PVC Foam Plastic Sheets - Self Adhesive

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application :

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

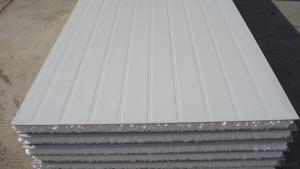

The difference between PVC free foam board and celuka/crust foam board:

PVC celuka/crust foam board is a kind of PVC foam boards we recommended to our customers as they have superior quality.

The extrusion line adopts celuka foam technology. These processes result in a "skinning" or outer layer of the foam board and

harder or more scratch resistant. Compared with other PVC foam board, this kind of PVC foam board not only has much more

smooth surface, but also has better skin hardness, and the mechanical performance of the PVC celuka foam board is much

better than other PVC foam boards.

Bulk cargo packing: 1.8 tons per tray, use wooden pallets on bottom, with packaging film packages all around ensure transportation security.

Full container load packing: 18-20 tons of a 20 foot container with 10 tray.

Pictures

FAQ

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

- Q: Are plastic sheets resistant to cracking or splitting?

- Yes, plastic sheets are generally resistant to cracking or splitting due to their flexibility and durability.

- Q: How to distinguish the plate and plastic glasses frame? That kind of material is better.

- Plate design, surface more smooth, plastic better. Not easily deformed. Plastic frames are lighter. Relatively rough. Easily deformed. The plates will be slightly more plastic.

- Q: Can plastic sheets be used for window glazing?

- Yes, plastic sheets can be used for window glazing.

- Q: Can plastic sheets be used for roof skylights?

- Yes, plastic sheets can be used for roof skylights. Plastic skylights are a popular and cost-effective option for bringing natural light into indoor spaces. They are lightweight, durable, and offer good insulation properties. However, it is important to choose high-quality, UV-resistant plastic sheets to ensure long-term performance and prevent yellowing or degradation due to exposure to sunlight.

- Q: Is the extrusion plate the same as the foam board?

- Foam plastic plate: plastic foam or plastic sheet, or plastic sheet, foamed, washed or foamed

- Q: Can plastic sheets be used for horticultural purposes?

- Yes, plastic sheets can be used for horticultural purposes. They are often used as greenhouse covers or as barriers to protect plants from weather elements, pests, or diseases. Plastic sheets can help create a controlled environment for plants, maintaining optimal temperature and humidity levels. They are also commonly used for mulching, preventing weed growth, conserving moisture, and promoting plant growth.

- Q: Can plastic sheets be transparent?

- Yes, plastic sheets can be transparent.

- Q: How to choose the PVC plastic gusset plate of the ceiling?

- PVC plastic gusset plate suspended ceiling material is made of PVC resin as base material, adding a certain amount of anti-aging agent, modifier and other additives. It is made by mixing, rolling and vacuum plastic absorption.The utility model is especially suitable for the ceiling decoration of kitchens and bathrooms. PVC plastic Kouban ceiling pattern more varieties, varieties are available: white, beige, blue etc.;Design: Yuhua, peach, Xiong Zhu, Yunlong, lattice flower, mosaic.The main disadvantages of PVC are: high temperature resistance, easy working and deformation in hot environment.

- Q: I have an 8X11 plastic magnifying sheet that I need to cut in 1/2 so it fits in my books. Any Ideas on how to cut it.

- what the hell. with a penknife or scissors

- Q: How are plastic sheets made?

- Plastic sheets are typically made through a process called extrusion, where melted plastic is forced through a die to form a continuous sheet. The plastic pellets are first melted and then fed into a heated barrel, where they are forced through a rotating screw. The molten plastic is then pushed through a flat die, which determines the thickness and width of the sheet. As the plastic exits the die, it is cooled and solidified using either air, water, or a combination of both. The resulting plastic sheet can be cut and shaped according to specific requirements.

Send your message to us

1.5mm Black PVC Foam Plastic Sheets - Self Adhesive

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords