Aluminum Molding Strips - 1.5mm 2.0mm 2.5mm 3.0mm Aluminum Sheet in Coil for Heat Exchanger

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: shutters, doors...

(2).Exterior: wall cladding,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Charles Martin Hall of Ohio in the U.S. and Paul Héroult of France independently developed the Hall-Héroult electrolytic process that facilitated large-scale production of metallic aluminium. This process remains in use today.[73] In 1888, with the financial backing of Alfred E. Hunt, the Pittsburgh Reduction Company started; today it is known as Alcoa. Héroult's process was in production by 1889 in Switzerland at Aluminium Industrie, now Alcan, and at British Aluminium, nowLuxfer Group and Alcoa, by 1896 in Scotland.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

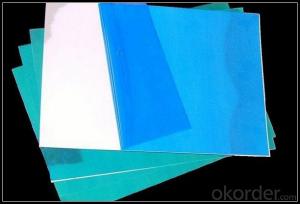

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: The question asks if it's possible to use aluminum strips for insulating the exterior walls of a building.

- <p>Yes, aluminum strips can be used for exterior wall insulation, but they are typically used as a vapor barrier or as part of a metal stud framing system rather than as an insulating material themselves. Aluminum is a good conductor of heat, so it's not an insulator. Instead, it's often used to create a barrier against moisture and air infiltration. For insulation, materials like fiberglass, cellulose, or foam are more appropriate. Aluminum strips can help secure insulation boards in place and provide a base for attaching exterior finishes.</p>

- Q: This question asks if it is permissible to use recycled metal sheets in construction within the user's specific geographical area.

- <p>The legality of using recycled metal sheets in construction projects varies by region and state. It is essential to consult local building codes and regulations, as they dictate the acceptable materials for construction. Some areas may have strict guidelines regarding the use of recycled materials due to concerns over structural integrity and safety. In other regions, there may be incentives or regulations promoting the use of recycled materials for environmental and sustainability reasons. Always check with your local building department or consult a construction professional to ensure compliance with all applicable laws and codes.</p>

- Q: Is it possible to utilize aluminum strips in a construction project focused on sustainability and environmental responsibility?

- <p>Yes, you can use aluminum strips for a green building project. Aluminum is a versatile and sustainable material due to its recyclability and low energy consumption in production. It also has a high strength-to-weight ratio, which can contribute to the energy efficiency of a building. However, it's important to consider the source of the aluminum and ensure it is produced with minimal environmental impact. Using recycled aluminum can further enhance the green credentials of your project.</p>

- Q: This question asks for the cost of aluminum strip roofing, which is a type of metal roofing material.

- <p>The cost of aluminum strip roofing can vary significantly based on factors such as the quality of the aluminum, the complexity of the installation, and regional pricing. On average, the cost of aluminum strip roofing ranges from $6 to $12 per square foot for the materials alone. This does not include labor costs, which can add another $3 to $10 per square foot. It's important to get quotes from multiple contractors in your area to get an accurate estimate for your specific project. Prices can fluctuate, so it's best to check current market rates for the most up-to-date information.</p>

- Q: Is it possible to use aluminum strips to construct a solar reflector system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a solar reflector system for your home or business. Aluminum is a reflective material and can be shaped into strips to reflect sunlight. These strips can be arranged in a way to direct sunlight towards solar panels or into specific areas to reduce the need for artificial lighting and heating. However, for optimal efficiency, you should consider the angle of reflection, the positioning of the strips relative to the sun's path, and the overall design of the system. Consulting with a professional in solar technology can help ensure that your solar reflector system is effective and safe.</p>

- Q: How can the aluminium band be welded to the steel shell?

- Welding method:1) to deal with the surface of the aluminum strip and steel shell surface oil and oxide skin.2) after the low temperature welding wire 303B Wei Odin flatto, then put between the aluminum strip and steel shell.3) the resistance is placed in the welding place where the flat 303B wire is welded.4) in the premise of high temperature continuous heating, 303B welding wire melting forming, bonding aluminum strip and steel shell.Welding attention method:1, resistance welding current output must be enough, otherwise the parent can not reach the temperature, welding wire will not be adhesive.2, the surface of the oxide film must be handled clean, so that the aluminum band is easy to glue, otherwise, the aluminum oxide film will hinder the welding line bonding aluminum belt.

- Q: This question asks about the differences between aluminum and stainless steel in terms of their ability to resist corrosion.

- <p>Yes, there are differences between aluminum and stainless steel in terms of corrosion resistance. Aluminum is highly resistant to corrosion due to the formation of a protective oxide layer on its surface, which prevents further oxidation. This makes it suitable for environments with high moisture or exposure to corrosive substances. Stainless steel, on the other hand, also has good corrosion resistance, especially when it contains higher amounts of chromium, which forms a passive film that protects the metal from corrosion. However, stainless steel can be more susceptible to corrosion in certain environments, such as those with chlorides, compared to aluminum.</p>

- Q: What types of aluminum strips are more appropriate for commercial use?

- <p>Yes, there are specific types of aluminum strips that are more suitable for commercial applications. These include 1100 series aluminum strips, known for their high purity and excellent formability, making them ideal for general commercial purposes. 3003 series aluminum strips are also popular due to their enhanced corrosion resistance and formability, suitable for applications requiring moderate strength and good workability. Additionally, 5052 series aluminum strips offer good corrosion resistance and weldability, making them suitable for applications in the marine and transportation industries. The choice of aluminum strip depends on the specific requirements of the commercial application, such as strength, corrosion resistance, and formability.</p>

- Q: This question asks for a list of various types of aluminum strips that are specifically used for exterior applications.

- <p>Aluminum strips used for exterior applications come in various types, each serving specific purposes. These include: 1) Architectural Aluminum Strips, used for facades and building exteriors due to their durability and weather resistance. 2) Anodized Aluminum Strips, which offer enhanced corrosion resistance and a wide range of colors for aesthetic appeal. 3) Extruded Aluminum Strips, known for their strength and customizability, suitable for structural applications. 4) Embossed Aluminum Strips, which provide a textured surface for improved grip or decorative purposes. 5) Heat Insulating Aluminum Strips, used to reduce heat transfer in exterior applications. 6) Reflective Aluminum Strips, used for safety markings or to enhance visibility in outdoor settings. Each type is chosen based on the specific requirements of the project, such as strength, appearance, and environmental conditions.</p>

- Q: What are the positive impacts on the environment when aluminum strips are used?

- <p>The environmental benefits of using aluminum strips include their recyclability, which reduces waste and conserves resources. Aluminum is highly recyclable, and its recycling process requires significantly less energy compared to producing new aluminum from raw materials. This leads to reduced greenhouse gas emissions and lower energy consumption. Additionally, aluminum strips are lightweight, which can decrease the carbon footprint associated with transportation. They are also corrosion-resistant, reducing the need for maintenance and replacement, and can be used in various applications, such as construction and packaging, to create more sustainable and eco-friendly products.</p>

Send your message to us

Aluminum Molding Strips - 1.5mm 2.0mm 2.5mm 3.0mm Aluminum Sheet in Coil for Heat Exchanger

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords