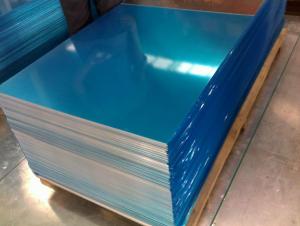

0.08mm Aluminum Sign Sheets with Heat Sealing Aluminum Foil Tapes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

| Packaging Details: | Packaging, marking, transport and storage Marking Adhesive tape per box should have the following marks: a) Producer name and address; b) Product name and specifications; c) Quantity and weight; d) Date of manufacture or batch number of production; e) Pressure prevention, moisture-roof and sunscreen signs; f) Expiration date. g) If meeting the RoHS requirements, the product packaging is RoHS labeled. Packaging The product is packaged by use of corrugated boxes, and plastic bags are packa |

| Delivery Detail: | AS SOON AS POSSIBLE |

Specifications

applicable to encapsulate the evaporation pipelines for refrigerator, freezer and other refrigeration systems.

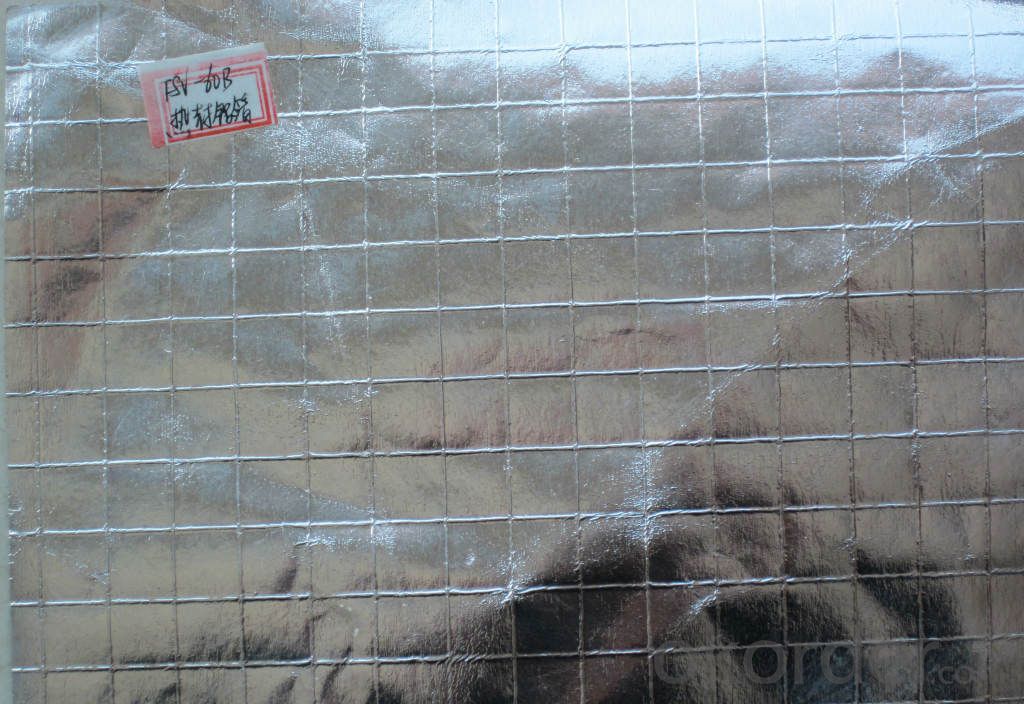

Aluminum foil tapes with heat sealing films

Aluminum foil tapes with heat sealing films

CODE | Acrylic Adhesive | Category | Thickness | Initial Stickiness | 180°Peeling Strength | Permanent Adhesion | Tensile Strength | Polyurethane Foam Adhesive Rate |

BLAMT-301 | Water-Based | Bopp | ≥0.07mm | ≥15# | 4n/cm | ≥24h | ≥25n/cm | |

BLAMT-302 | Oily | Bopp | ≥0.07mm | ≥15# | 6n/cm | ≥24h | ≥25n/cm | |

BLAMT-303 | Oily | Pe | ≥0.07mm | 7.5n/cm | ≥24h | ≥25n/cm | ≥60% | |

BLAMT-304 | Oily | Bopp | ≥0.07mm | 7.5n/cm | ≥24h | ≥25n/cm | ≥60% |

Aluminum foil coated adhesive tape

Composition and characteristics:

with aluminum foil as the base material, the back of the base material is coated with a layer of polypropylene (BOPP) or polyethylene (PE) film and coated with special release agent, and the front face is coated with factice or glue.

Main usage:

applied for encapsulating and winding evaporation pipelines for refrigerator, freezer and other refrigeration equipment, this tape has outstanding sealing and heat preservation performance, and it is easy and convenient to operate. The back of the products 303 and 304 is applied with special release agent and then they can be connected with polyurethane foam, so the heat sealing performance is more outstanding.

The above parameters are for reference only,

and special requirements can be applicable according to actual demands of users

- Q: write a balanced equation for the reaction between aluminium metal and potassium hydroxide in water

- Hi there! So you're given Aluminum metal, which has the oxidation state (almost always) of 3+. In play are: Al 3+ K+ OH- You have KOH(aq) + Al 3+ and they react to form a precipitate, creating Al(OH)3 and the potassium cation disperses into solution. In traditional symbols: 3 KOH (aq) + Al 3+(s) ----- Al(OH)3(s) + 3K+ (aq) That's 3 K+, 3 OH-, and 1 Al 3+. That carries for both sides! NIE would look like: 3 OH- + Al 3+ ----- Al(OH)3 (s) Most instructors don't mind if you leave off (aq) but pretty much all of them care about (s), so make sure you add those phase states! I hope I helped :)

- Q: What is the thickness of the aluminum sheets?

- The thickness of the aluminum sheets can vary depending on the specific product or application. Aluminum sheets are available in a wide range of thicknesses, typically ranging from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm) or even thicker. The appropriate thickness will depend on the specific requirements and intended use of the aluminum sheet.

- Q: What are the specific rules or codes that govern the use of aluminum sheets in residential construction?

- <p>Yes, there are special regulations related to using aluminum sheets in residential buildings. These regulations can vary by country, state, or municipality, but generally, they cover aspects such as material standards, fire resistance, structural integrity, and energy efficiency. For example, aluminum sheets must meet specific thickness and strength requirements to ensure structural safety. They must also comply with fire codes, which may require certain fire-resistant coatings or treatments. Additionally, energy codes may dictate the insulation value of aluminum sheets used in walls or roofs to improve thermal performance. It's crucial to consult local building codes and regulations to ensure compliance when using aluminum sheets in residential construction.</p>

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum sheets as a roofing material.

- <p>Aluminum sheets for roofing offer several advantages, including durability, resistance to rust and corrosion, lightweight nature, and energy efficiency due to reflective properties. They are also easy to install and maintain, and can be recycled, making them environmentally friendly. However, there are some disadvantages such as being more expensive than some other roofing materials, potential for denting if not properly installed, and noise issues during heavy rain or hail due to their lightweight nature. Additionally, they may require more frequent replacement compared to some other materials.</p>

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: What is the weight of aluminium plate now?

- The following is the density of each series of aluminum sheets for reference.Pure aluminum 2.7 TC7 4.4Antirust aluminium LF2, LF43 2.68, TC8 4.48LF3 2.67 TC9 4.52LF5, LF10, LF11 2.65, TC10 4.53LF6 2.64 pure nickel, anode nickel, electric vacuum nickel 8.85LF21 2.73, nickel, copper, nickel, magnesium, nickel silicon alloy 8.85Hard aluminium, LY1, LY2, LY4, LY6 2.76, Ni Cr alloy 8.72LY3 2.73 (Zn0.1, Zn1, zinc, Zn2, Zn3) 7.15LY7, LY8, LY10, LY11, LY14 2.8, cast zinc 6.86LY9, LY12 2.78, 4-1 casting zinc aluminum alloy 6.9LY16, LY17 2.84, 4-0.5 casting zinc aluminum alloy 6.75Wrought aluminium LD2, LD30 2.7 lead and lead antimony alloy 11.37LD4 2.65 lead anode plate 11.33LD5 2.75

- Q: What are the safety standards for using aluminum sheets in construction?

- <p>Yes, there are safety standards related to using aluminum sheets in construction projects. These standards ensure the material's structural integrity, durability, and safety. They include specifications for thickness, strength, and quality of aluminum sheets, as well as guidelines for their installation to prevent issues like corrosion, fire hazards, and structural failure. Compliance with these standards is crucial for the safety of the construction workers and the longevity of the building.</p>

- Q: What are the methods to protect aluminum sheets from corrosion during their usage?

- <p>To prevent corrosion of aluminum sheets during use, several strategies can be employed. First, apply a protective coating such as paint, anodizing, or a conversion coating to create a barrier against corrosive elements. Second, ensure proper cleaning and drying to avoid the accumulation of moisture and contaminants. Third, use corrosion inhibitors in environments where aluminum is exposed to aggressive chemicals. Fourth, maintain good ventilation to reduce humidity levels. Finally, regularly inspect and maintain the aluminum sheets to address any signs of corrosion early. These measures can significantly extend the lifespan and performance of aluminum sheets.</p>

- Q: Can aluminum sheets be used for kitchen backsplashes?

- Yes, aluminum sheets can be used for kitchen backsplashes. Aluminum is a durable and lightweight material that is resistant to moisture and stains, making it a suitable choice for kitchen backsplashes. Additionally, aluminum sheets are easy to clean and maintain, making them a practical option for any kitchen.

Send your message to us

0.08mm Aluminum Sign Sheets with Heat Sealing Aluminum Foil Tapes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords