Clear OPP Adhesive Packaging Tape with Cold Heat and Aging Resistance Cloth Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Cloth Tape is of polyethylene cloth as the carrier, coating with hot melt adhesive, synthetic rubber adhesive or nature rubber. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Cloth Tape: widely used for pipe wrapping, gaffers and book binding etc.

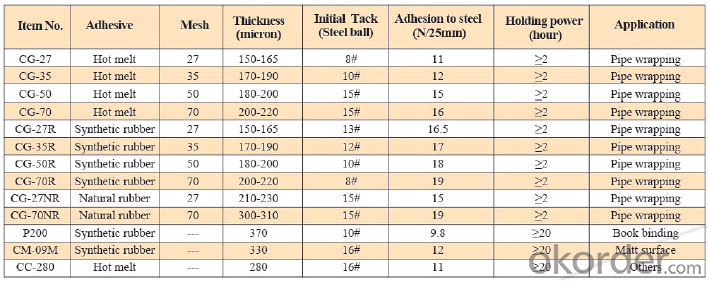

Typical Physical Reports of Bopp Tape

The thickness of the tape can be customized.

Log Roll: Length 1000mm; width 1060mm.

Cut Roll: As per customer’s requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Cloth Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing plastic garment bags?

- Yes, packaging tape can be used for sealing plastic garment bags. Packaging tape is designed to provide a secure and durable seal on various materials, including plastic. It can help keep the plastic garment bag tightly sealed, preventing dust, moisture, and other contaminants from entering the bag and potentially damaging or dirtying the garments inside. Additionally, packaging tape is typically easy to use, as it can be easily cut with a dispenser or a pair of scissors, making it convenient for sealing plastic garment bags.

- Q: How do I prevent packaging tape from wrinkling?

- To prevent packaging tape from wrinkling, there are a few things you can do: 1. Use a tape dispenser: A tape dispenser helps ensure a smooth application of tape, reducing the chances of it wrinkling. It also provides better control while taping, making it easier to keep the tape straight and tight. 2. Apply the tape with tension: When applying the tape, pull it tightly as you stick it down. This helps prevent any slack or loose areas that could cause wrinkling. Be careful not to stretch the tape too much, as it may lose its adhesive properties. 3. Use the right type of tape: Different types of packaging tape have different adhesive properties and thicknesses. Choosing a high-quality tape specifically designed for packaging can help minimize wrinkling. Additionally, consider using a tape with reinforced fibers for added strength and resistance to wrinkling. 4. Ensure a clean surface: Before applying the tape, make sure the surface is free from dust, dirt, or any other debris. These particles can cause the tape to wrinkle or not adhere properly. Clean the surface thoroughly and dry it before taping. 5. Avoid extreme temperatures: Packaging tape can be sensitive to temperature changes, which may lead to wrinkling. Avoid using the tape in extremely cold or hot environments. If possible, store the tape in a controlled temperature area before use. 6. Apply pressure: After applying the tape, run your hand or a roller over it to ensure good adhesion. This helps smoothen out any potential wrinkles or bubbles and ensures that the tape is securely attached. By following these tips, you can significantly reduce the chances of packaging tape wrinkling, resulting in a neater and more secure package.

- Q: Can packaging tape be used for sealing metal boxes?

- Yes, packaging tape can be used for sealing metal boxes. Packaging tape is designed to provide a secure and durable seal on various surfaces, including metal. It offers a strong adhesive that can effectively stick to metal surfaces, ensuring that the box remains sealed during transportation or storage. However, it is important to choose a packaging tape that is suitable for heavy-duty applications and can withstand the weight and pressure that may be exerted on the metal box. Additionally, it is recommended to clean the metal surface before applying the tape to ensure proper adhesion.

- Q: Does packaging tape come in different finishes or textures for aesthetic purposes?

- Yes, packaging tape does come in different finishes or textures for aesthetic purposes. While the primary function of packaging tape is to securely seal boxes and packages, manufacturers have recognized the importance of aesthetics in packaging. As a result, they have developed packaging tapes with various finishes and textures to meet different aesthetic preferences. Some packaging tapes come in glossy finishes, which can give a more polished and professional look to the package. These tapes often have a smooth and shiny surface that reflects light, making the package appear more visually appealing. Glossy packaging tapes are commonly used in industries that require a high-end presentation, such as luxury goods or high-quality products. On the other hand, there are also packaging tapes with matte or satin finishes. These tapes have a more subtle and refined appearance, providing a sophisticated look to the package. Matte or satin tapes are often favored in industries that value a more subtle and understated aesthetic, such as cosmetics or boutique products. Apart from finishes, packaging tape can also come in different textures. For example, some tapes have a textured or patterned surface, which adds a tactile element to the packaging. These tapes can have embossed patterns, such as dots, stripes, or even company logos, which can enhance the overall visual appeal and uniqueness of the package. In summary, packaging tape does come in different finishes or textures for aesthetic purposes. Whether it is a glossy, matte, satin, or textured surface, these variations allow businesses to choose packaging tape that aligns with their branding and desired presentation. By utilizing different finishes and textures, packaging tape can not only serve its primary function but also contribute to a more visually appealing and customized packaging experience.

- Q: I'd like to know the specifications of the sealing tape. How do you see it? (the following two examples) product name: sealing tape product type: 2.5 inch product specifications: 57mm*80 code (8.5mm thick) weight: about 0.145KG the price for volume: Specifications: code number 48mm*150 meters *40u flesh 20mm here refers to what? I know that 40U means stickiness, so how do I see that?

- Therefore, the seal tape specification is expressed by "width * length * thickness".

- Q: Can packaging tape be used for sealing electronics or appliances?

- Packaging tape is not recommended for sealing electronics or appliances. While packaging tape is designed to securely seal cardboard boxes and packages, it is not suitable for sealing electronics or appliances due to various reasons. Firstly, packaging tape does not provide adequate protection against moisture or dust, which can be harmful to electronic components. Electronics and appliances require airtight sealing to prevent any damage or corrosion caused by moisture or dust particles. Secondly, packaging tape is not designed to withstand high temperatures or extreme conditions that electronics or appliances may be subject to during storage or transportation. The adhesive used in packaging tape may not be able to withstand heat or cold, which could lead to the tape peeling off and leaving the item unprotected. Thirdly, electronics and appliances often have delicate surfaces that can be easily scratched or damaged by the adhesive on packaging tape. The sticky residue left behind by the tape can also be difficult to remove from sensitive surfaces. Therefore, it is advisable to use appropriate sealing methods and materials specifically designed for electronics or appliances. These may include specialized tapes, foam gaskets, or custom-fitted protective covers. It is always recommended to consult the manufacturer's guidelines or seek professional advice when sealing electronics or appliances to ensure proper protection and functionality.

- Q: Can packaging tape be used for sealing office supplies or stationery?

- Yes, packaging tape can be used for sealing office supplies or stationery. It provides a strong and secure seal to keep items protected and organized.

- Q: How does packaging tape perform in dusty environments?

- Packaging tape generally performs well in dusty environments, but its effectiveness may vary depending on the specific conditions and the quality of the tape. Dust particles can potentially interfere with the adhesion of the tape, making it less sticky and less reliable in securing packages. However, most packaging tapes are designed to be resistant to dust and other contaminants, and they have a strong adhesive backing that can withstand moderate levels of dust. In dusty environments, it is recommended to choose packaging tapes that have a higher tack or adhesive strength. These tapes are specifically engineered to provide better adhesion and stickiness, even in dusty conditions. Additionally, selecting tapes with a thicker backing material can also help to prevent dust particles from penetrating through the tape and compromising its adhesive properties. It is important to note that excessive dust accumulation may still impact the performance of packaging tape, especially if the dust is fine and abundant. In such cases, it is advisable to regularly clean the package surfaces before applying the tape to ensure optimal adhesion. Adequate surface preparation, such as wiping down the area with a clean cloth or using compressed air to remove the dust, can help improve the tape's performance in dusty environments. Overall, while packaging tape can generally perform well in dusty environments, it is essential to consider the quality of the tape, the level of dust exposure, and the proper surface preparation to ensure optimal adhesion and package security.

- Q: Is packaging tape resistant to UV rays?

- Yes, packaging tape is typically designed to be resistant to UV rays.

- Q: How does packaging tape perform in high-pressure conditions?

- Packaging tape is designed to provide reliable adhesion and sealing under various conditions, including high-pressure environments. In high-pressure conditions, such as during shipping or transportation, packaging tape performs exceptionally well due to its strong adhesive properties and durable construction. The adhesive used in packaging tape is typically a pressure-sensitive adhesive (PSA), which means it adheres to surfaces when pressure is applied. This allows the tape to create a secure bond with the packaging material, even under high-pressure conditions. The tape's adhesive strength ensures that it remains firmly attached to the package, preventing any potential damage or tampering during transit. Moreover, packaging tape is often made from sturdy materials such as polypropylene or PVC, which further enhances its performance in high-pressure conditions. These materials provide excellent tensile strength, meaning they can withstand significant pressure without breaking or tearing. This ensures that the tape maintains its integrity and keeps the package sealed and protected. Additionally, packaging tape is often resistant to moisture, temperature changes, and other environmental factors that can impact its performance. This resistance helps the tape maintain its adhesive strength and structural integrity even in demanding conditions, including high-pressure environments. Overall, packaging tape is specifically engineered to perform well in high-pressure conditions. Its strong adhesive properties, durable materials, and resistance to various environmental factors make it a reliable choice for ensuring package integrity and protection during shipping or transportation.

Send your message to us

Clear OPP Adhesive Packaging Tape with Cold Heat and Aging Resistance Cloth Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches