Lumi Low and Medium Quality OPP Packing Tapes

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of OPP Packing Tape

OPP packing tape are made of BOPP films coated with acrylic adhesive.

Application of OPP Packing Tape

1. Industrial box parking

2. outside electronics product packing with safety material

3. gift wrapping &decoration

4. general purpose repair

5. bundling &strapping

6. stationery purpose

Advantage of OPP Packing Tape

1.Packing tape, superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of OPP Packing Tape

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100rolls/carton(according to different specifications)

carton size : any carton size as your request

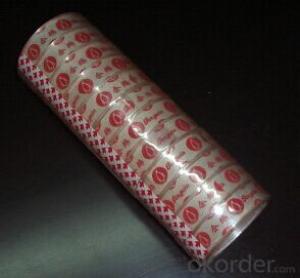

Pictures of OPP Packing Tape

Specification of OPP Packing Tape

| Material | OPP |

| Adhesive Side | Single Sided. |

| Adhesive | Acrylic, Water based acrylic adhesive |

| Acrylic | Water based acrylic adhesive |

| Color | Transparent clear/yellowish /tan brown/blue/red/ green |

| Normal thickness | 36mic, 38mic, 40mic, 43mic, 45mic, 46mic, 48mic,50mic, 52mic |

| Packaging | Single packed, shrink film packed, depend on customer’s request |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Yes, packaging tape can be used for sealing packages with high-value contents. Packaging tape is specifically designed to securely seal packages, providing protection against tampering, moisture, and damage during transit. It is strong, durable, and often features a strong adhesive backing that creates a long-lasting seal. When applied properly, packaging tape can effectively secure packages containing high-value contents, ensuring their safe delivery. However, it is important to consider additional security measures, such as using tamper-evident tape or adding extra layers of protection, depending on the value and fragility of the contents.

- Q: Can packaging tape be used for sealing construction materials or tools?

- Yes, packaging tape can be used for sealing construction materials or tools. Packaging tape is designed to securely seal boxes and packages, so it can also be used to seal construction materials or tools. It provides a strong and durable bond, making it suitable for sealing various types of materials such as wood, metal, plastic, or concrete. However, it is important to consider the weight and the nature of the materials being sealed. For heavier or more demanding construction applications, it may be more appropriate to use specialized tapes or adhesives specifically designed for construction purposes.

- Q: How does packaging tape perform on high-friction surfaces?

- Packaging tape is designed to adhere to a wide variety of surfaces, including high-friction surfaces. Its performance on high-friction surfaces can vary depending on the specific tape and the nature of the surface. In general, packaging tape is equipped with strong adhesive properties that allow it to stick securely to surfaces, even those with high friction. The adhesive on the tape is formulated to provide excellent tackiness and bonding strength, ensuring that it stays in place and maintains its hold on high-friction surfaces. However, it is important to note that excessive friction or roughness on a surface can potentially affect the tape's adhesion. If the surface is extremely rough or uneven, it may create air pockets or gaps between the tape and the surface, which can compromise its performance. In such cases, it is advisable to prepare the surface properly by cleaning and smoothing it before applying the tape to ensure optimal adhesion. Additionally, the durability of the tape can play a role in its performance on high-friction surfaces. Some packaging tapes are reinforced with fibers or have a thicker construction, making them more resistant to wear and tear caused by friction. These tapes are often recommended for heavy-duty applications or when packaging items that will be subjected to constant rubbing or sliding on high-friction surfaces. Overall, packaging tape is generally well-suited for use on high-friction surfaces. Its adhesive properties, combined with proper surface preparation and selection of a suitable tape, can ensure reliable and long-lasting adhesion, even in challenging conditions.

- Q: What are the benefits of using pre-printed packaging tape with warning messages?

- There are several advantages to using pre-printed packaging tape with warning messages. To begin with, it increases safety by clearly informing handlers of potential package hazards. These warning messages can include instructions like "Fragile," "Handle with Care," or "Do Not Stack," which prevent mishandling and reduce the risk of damage during shipping or transportation. By providing this crucial information upfront, pre-printed packaging tape ensures that fragile or sensitive items are handled properly, decreasing the likelihood of breakage, leakage, or other accidents. Additionally, it saves time and effort because the warning messages are already printed on the tape. This eliminates the need to separately apply warning labels or write instructions on the package, streamlining the packaging process. It also reduces the chances of labeling errors or inconsistencies since the pre-printed tape ensures a standardized and professional appearance. Moreover, using pre-printed packaging tape with warning messages enhances brand image and customer satisfaction. It demonstrates a dedication to quality and safety, which positively influences customer perception. It also helps establish trust and confidence in the company's products or services since customers can see that proper precautions are being taken to ensure the secure delivery of their items. Lastly, pre-printed packaging tape with warning messages can serve as a marketing tool. By incorporating the company logo, contact information, or promotional messages on the tape, businesses can effectively promote their brand and leave a lasting impression on customers. This increased visibility can boost brand recognition and potentially attract new customers. In conclusion, using pre-printed packaging tape with warning messages offers numerous benefits, including improved safety, time and effort savings, enhanced brand image, and marketing opportunities. It is a practical and efficient solution for businesses seeking to guarantee the secure and efficient transportation of their products.

- Q: Due to delivery to customers, buy sealed box with more than 3 thousand yuan, borrow? The loan? Thank you!

- The main variety of high-temperature polyimide tape, PET tape, high temperature tape, masking tape, Teflon tape, double-sided tape. High temperature resistant adhesive tape, industrial tape, conductive tape, insulation tape, packing tape, fiber tape, protective film, PI tape, Teflon tube, Teflon tape, cloth tape

- Q: Can packaging tape be used for sealing packages with electronics or electrical components?

- Sealing packages containing electronics or electrical components with packaging tape is possible. However, it is essential to understand that not all packaging tapes are suitable for this purpose. To ensure the safety of the items, it is advised to opt for an anti-static or ESD-safe tape. These tapes are specifically crafted to shield sensitive electronic components from static electricity during transportation or handling. Using regular packaging tape lacking anti-static properties may expose the electronics to the risk of static discharge, potentially leading to damage or compromised performance. Therefore, it is crucial to carefully assess the specific requirements of the electronics being packaged and select an appropriate tape accordingly, guaranteeing their protection.

- Q: Is packaging tape safe to use on plastic hangers?

- Packaging tape is generally safe for use on plastic hangers, as it is designed to securely hold items together and can adhere well to various surfaces, including plastic. However, it is important to take into account the type of plastic hanger and its intended purpose. While packaging tape may be suitable for temporarily securing clothes on a plastic hanger, it could potentially leave residue or cause damage if left for an extended period. It is recommended to test a small area of the hanger first to ensure that the tape does not cause any harm or leave marks. Moreover, if the plastic hanger is used for displaying or storing delicate or valuable clothing, it might be better to consider gentle alternatives such as fabric-friendly tape or non-adhesive hanger attachments.

- Q: Is packaging tape resistant to extreme temperatures or weather conditions?

- Packaging tape is typically constructed to endure extreme temperatures and diverse weather conditions, although the degree of resistance may fluctuate depending on the tape's specific type and quality. Most packaging tapes are composed of robust materials like polypropylene or PVC, renowned for their durability and ability to withstand environmental elements. These tapes are often treated with specialized adhesives that retain their stickiness even in harsh temperatures or humid surroundings. Concerning extreme temperatures, packaging tapes are generally engineered to withstand a broad spectrum, including both frigid and scorching extremes. They can typically endure temperatures as low as -20 degrees Celsius or as high as 60 degrees Celsius without compromising their adhesive properties or becoming brittle. Similarly, packaging tapes are designed to exhibit resistance against diverse weather conditions. They are formulated to repel moisture, humidity, and UV radiation, which are prevalent factors that can deteriorate tape quality. This resistance ensures that the tape remains intact and efficient, even when exposed to rain, snow, or direct sunlight. It is crucial to note that although packaging tape is generally resistant to extreme temperatures and weather conditions, prolonged exposure to such circumstances can still impact its durability. Therefore, it is advisable to store and utilize packaging tape in a controlled environment whenever feasible to guarantee maximum effectiveness.

- Q: Can packaging tape be used for sealing moving boxes?

- Indeed, when it comes to sealing moving boxes, packaging tape proves to be quite useful. Its design is specifically tailored to secure boxes and packages during transit, boasting durability and strength that ensure a tight seal, preventing boxes from opening or items from spilling out. Moreover, its application is quick and effective, making it an easy-to-use option. It is worth noting that packaging tape often possesses resistance against moisture and can withstand diverse weather conditions, which makes it an ideal choice for long-distance moves or storage purposes. In summary, packaging tape is a dependable solution for sealing moving boxes and guaranteeing the safety of your belongings throughout the moving process.

- Q: Can packaging tape be used for sealing packages with electronic components?

- Indeed, packaging tape possesses the capability to seal packages containing electronic components effectively. Its purpose is to furnish packages with a sturdy and long-lasting seal, safeguarding the contents from external factors like moisture, dust, and physical harm. When sealing packages that house electronic components, it becomes crucial to verify the tape's strength in order to maintain package integrity and offer sufficient protection. Moreover, it is advisable to employ anti-static packaging tape exclusively created for electronic components, as this type aids in the dissipation of static electricity and serves as a preventive measure against potential harm to delicate electronics.

Send your message to us

Lumi Low and Medium Quality OPP Packing Tapes

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches