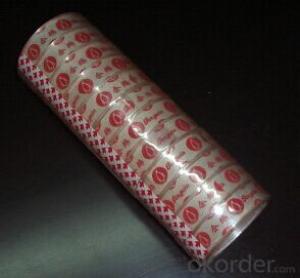

Low Noise Packaging Tape for Cloth, Duct, Pipe & Silver - Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 roll

- Supply Capability:

- 6000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

1.Carrier: Polyethylene Cloth

2.Adhesive: Hot Melt Adhesive,Synthetic Rubber Adhesive,Natural Rubber

3.Mesh: from 27 to 70

4.Color: According to your request

5.Type:Normal Duct Tape for Pipe Wrapping

Gaffers Tape

Cotton Cloth Tape

Book Binding Cloth Tape

2. Advantages

1 ) Different temperature resistance with good adhesion.

2 ) High tensile strength, good resistance of damage,no residue, eco-friendly.

3 ) Printing logo on paper core and carton mark as customers' need

4 ) SGS, ISO,BV, CTI certificates approved

5)Professional teamwork for orders

6)No.365 on the 2012 Fortune Global 500

7) Professional manufacturer with 31 years experiences of adhesive tapes

Special size,color can be made according to customer's requirement

3. Application

1) Used for normal masking, such as indoor painting, car painting, car decoration painting.

2) Used in electronic industry and electric appliances for fixing and protection purposes.

3) Mainly designed for ordinary wrapping ,craftwork, lightduty masking.

4) Furniture, appliance automobile /shoes spray painting, color making, decoration and labels.

4. Details

Material | Cloth Tape |

Used | Widely Used |

Printing | Offer printing |

Color | Red, milky, green, white , yellowish, blue, black, or at will. |

Packaging | 6rolls/shrink,12rolls/shrink,72rolls/ctn,144rolls/ctn. |

MOQ | 20ft container or as you need. |

Payment terms | 30% in advance,70% balance the copy of B/L. |

Delivery time | 15workdays except the affirming date of logo on paper core and carton after receiving the deposit. |

Jumbo rolls size

| 1260mm*1800m, 1260mm*1000m |

Width | 3mm~1260mm normal width:12mm,18mm,24mm,36mm

|

Length | 10m~1800m normal length: 20m,33m,50m,100m |

Port | Shenzhen |

Certifications | ISO.9001.2008. and SGS. |

About Us:

CNBM International Corp.,established in 2004,is the business entity for trade and logistics of CNBM Group,a state-owned company under the direct supervision of State-owned Assets Supervison and Administration Commission of the State Council of People's Republic of China.

We are the adhesive tape division of CNBM International Corporation.Over the past decade we have been developed into a leading manufacturer of adhesive tapes in China.We mainly supply various kinds of adhesive tapes as BOPP packing tape,cloth duct tape,double sided taps,PVC tapes,Aluminum foil tape etc.

- Q: Does packaging tape have any specific safety precautions?

- Yes, packaging tape does have some specific safety precautions that should be followed. Firstly, it is important to handle packaging tape with care and avoid any sharp or sudden movements that could cause injury. While packaging tape itself is not typically dangerous, mishandling it could result in cuts or punctures. Additionally, it is essential to use the appropriate type of packaging tape for the intended purpose. Different tape materials and adhesives are designed for various applications, such as sealing boxes or securing heavy items. Using the wrong type of tape may result in inadequate sealing or potential hazards. Furthermore, it is crucial to store packaging tape in a safe place away from extreme temperatures, moisture, or direct sunlight. These factors can affect the tape's adhesive properties and compromise its effectiveness. Lastly, when using packaging tape, it is advisable to wear protective gloves if necessary, especially when handling sharp or heavy objects. This can provide an extra layer of safety and prevent any potential injuries. By following these safety precautions, users can effectively utilize packaging tape while minimizing the risk of accidents or harm.

- Q: What is the difference between acrylic and hot melt adhesive for packaging tape?

- The main difference between acrylic and hot melt adhesive for packaging tape lies in their composition and performance. Acrylic adhesive is made from water-based acrylic polymers and offers excellent clarity and UV resistance. It is ideal for long-term storage and can withstand temperature fluctuations. Hot melt adhesive, on the other hand, is a synthetic rubber-based adhesive that provides instant bonding and superior tack. It is suitable for applications requiring immediate adhesion and performs well in high-temperature environments. Overall, the choice between acrylic and hot melt adhesive depends on the specific packaging needs and conditions of use.

- Q: Is packaging tape safe to use on plastic picture frames?

- Yes, packaging tape is generally safe to use on plastic picture frames. It provides a secure and temporary hold without causing damage to the frame's surface. However, it is important to remove the tape carefully to avoid peeling off any paint or finish.

- Q: Can packaging tape be used for sealing arts and crafts materials?

- Packaging tape is indeed suitable for sealing arts and crafts materials. Its versatility as an adhesive enables it to effortlessly attach and secure a wide range of materials such as paper, cardboard, fabric, and more. Whether you need to seal envelopes, wrap gifts, or engage in art projects, packaging tape guarantees a sturdy and durable bond, ensuring the secure sealing of your arts and crafts materials. Moreover, its transparent nature allows it to seamlessly blend with your project, making it an exceptional option for sealing arts and crafts materials.

- Q: Is packaging tape resistant to chemicals?

- Packaging tape is typically resistant to a wide range of chemicals. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC), which are known for their chemical resistance properties. These materials have the ability to withstand exposure to various chemicals, including solvents, acids, and bases. However, it is important to note that the level of chemical resistance can vary depending on the specific type and quality of packaging tape being used. Some tapes may have a higher resistance to chemicals than others. Additionally, the duration and intensity of chemical exposure can also affect the tape's resistance. To ensure the tape's chemical resistance, it is recommended to check the manufacturer's specifications and guidelines regarding chemical compatibility. If you are dealing with particularly harsh chemicals or specialized applications, it may be necessary to seek out specific types of packaging tapes that are specifically designed for those conditions.

- Q: Can packaging tape be used for sealing packages with irregular shapes?

- Indeed, when it comes to sealing packages with irregular shapes, packaging tape comes in handy. Its flexibility and adhesive nature make it perfect for securing packages of different sizes and contours. Thanks to its strong adhesive properties, packaging tape can adhere to various surfaces, even those that are uneven or irregular, ensuring that the package remains tightly sealed during transportation. Moreover, packaging tape is known for its durability and tear-resistance, providing an added layer of protection for the package. Consequently, whether the package boasts an irregular shape or not, packaging tape proves to be a dependable and efficient choice for sealing it securely.

- Q: Can packaging tape be used for sealing packages for international shipping?

- Yes, packaging tape can be used for sealing packages for international shipping. It provides a reliable and secure seal that can withstand the rigors of transportation, ensuring the contents of the package remain intact during their journey.

- Q: Can packaging tape be used for sealing packages with heavy-duty construction materials?

- Yes, packaging tape can be used for sealing packages with heavy-duty construction materials. However, it is recommended to use a high-quality, heavy-duty packaging tape specifically designed for securing heavy items.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. It is commonly used to reinforce and stabilize palletized goods by securing them together, preventing shifting or toppling during transportation or storage.

- Q: Is packaging tape resistant to UV rays?

- Yes, packaging tape is typically designed to be resistant to UV rays.

Send your message to us

Low Noise Packaging Tape for Cloth, Duct, Pipe & Silver - Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 roll

- Supply Capability:

- 6000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords