Polypropylene Packaging Tape Wide 19mm*9m Insulating Tape Color 5 Rolls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

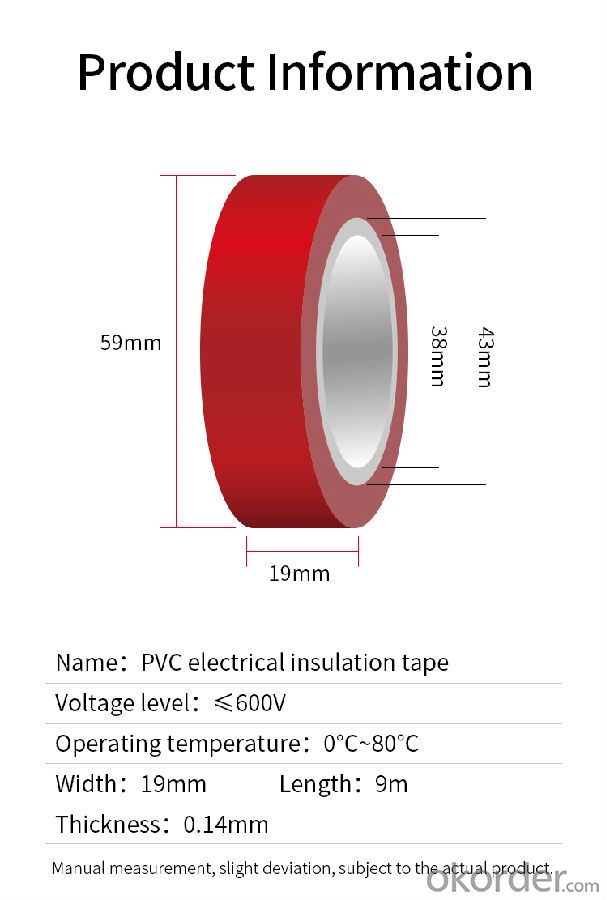

Specification: 0.13mm*19mm*9M (the actual length is 10M), Class A flame retardant, each 5 rolls is a heat shrinkable color, five colors of red, yellow, blue, green and black are one roll, the outer diameter of the paper tube is 42mm, shrink bag Stick a small sticker (provided by our company) on the outside, and the tape should be wound tightly to prevent deformation. Product weight 1.8 kg Product length 5.9cm Product width 5.9cm Product height 9.5cm

Q&A Q:Does our product support customization? A:Our products can support customization, but there are requirements for the quantity, you can contact us for details. Q:When you call or send a quotation request, what information do you need to provide? A:Your needs for the product, and what you want to know in detail. |

- Q: Can packaging tape be used for sealing plastic tubing?

- Yes, packaging tape can be used for sealing plastic tubing. Packaging tape is designed to provide a strong and secure seal on various surfaces, and it can adhere well to plastic materials. However, it is important to consider the specific application and requirements of the plastic tubing. If the tubing is meant to contain liquids or gases under pressure, or if it requires a more permanent and durable seal, it may be more appropriate to use specialized sealing methods such as heat sealing or using specific types of adhesives designed for plastic materials. Ultimately, the suitability of packaging tape for sealing plastic tubing depends on the specific circumstances and requirements of the application.

- Q: Does packaging tape come with a dispenser?

- Yes, packaging tape often comes with a dispenser for easy and convenient use.

- Q: Can packaging tape be used for sealing sports equipment or gear?

- Indeed, sports equipment or gear can be sealed using packaging tape. With its robust adhesive properties, packaging tape proves to be an excellent choice for securing and sealing a range of items, including sports equipment. By securely fastening the equipment and gear, it effectively safeguards them against potential damage when being transported or stored. Nonetheless, it's crucial to take into account the unique demands and specifications of the sports equipment or gear being sealed, as certain items may necessitate specialized tapes or sealing techniques to ensure optimal protection.

- Q: What is the purpose of packaging tape?

- The purpose of packaging tape is to securely seal and reinforce packages, boxes, or containers during storage, transportation, or shipping. It is designed to provide a strong, long-lasting bond that keeps the contents of the package intact and protected. Packaging tape also serves as a visual indicator of tampering, as any unauthorized opening or tampering can be easily identified. Additionally, it helps to prevent dust, moisture, and other external elements from entering the package, ensuring the integrity and quality of the enclosed items. Overall, the purpose of packaging tape is to provide a reliable and efficient solution for sealing and protecting packages, making it an essential tool for businesses, individuals, and organizations involved in shipping and logistics.

- Q: What are the benefits of using colored packaging tape?

- There are several benefits of using colored packaging tape. Firstly, colored packaging tape allows for easy identification and organization of different items or packages. By using different colors for specific products or categories, it becomes much simpler to quickly locate and retrieve the desired items. This can be especially helpful in warehouses or storage facilities with a large volume of goods. Secondly, colored packaging tape can act as a visual indicator or warning. It can be used to highlight fragile or delicate items, ensuring that they are handled with care during shipping or transport. This can help prevent damage and reduce the risk of mishandling. Additionally, colored packaging tape can be used for branding purposes. By using tape in company colors or with a custom design, businesses can enhance their brand visibility and recognition. This can make their packages stand out amongst others and leave a lasting impression on customers. Furthermore, colored packaging tape can also serve as a security measure. Some tapes are tamper-evident, meaning that it leaves a visible mark or shows signs of tampering if someone tries to open the package. This can help protect the contents of the package and provide reassurance to both senders and recipients. Lastly, colored packaging tape can simply add a touch of aesthetics to the packaging. With a wide range of colors and designs available, businesses can choose tape that complements their branding or adds a pop of color to their packaging, making it more visually appealing. In summary, the benefits of using colored packaging tape include easy identification and organization, visual indicators for fragile items, branding opportunities, security measures, and aesthetic enhancements.

- Q: Can packaging tape be used for sealing cosmetic or beauty products?

- Sealing cosmetic or beauty products with packaging tape is indeed possible. However, it is crucial to consider the suitability of the chosen tape for the product's specific requirements. If the cosmetic or beauty item is sensitive to heat or moisture, it is advisable to opt for a specialized tape that offers enhanced protection against these elements. Moreover, ensuring that the selected packaging tape is safe for use on the skin or any part of the body is of utmost importance. Some tapes may contain adhesives or materials that could potentially cause irritation or allergic reactions. Therefore, it is recommended to carefully evaluate the specific needs of the cosmetic or beauty product and select a packaging tape that can effectively and safely meet those requirements.

- Q: I'd like to know the specifications of the sealing tape. How do you see it? (the following two examples) product name: sealing tape product type: 2.5 inch product specifications: 57mm*80 code (8.5mm thick) weight: about 0.145KG the price for volume: Specifications: code number 48mm*150 meters *40u flesh 20mm here refers to what? I know that 40U means stickiness, so how do I see that?

- Therefore, the seal tape specification is expressed by "width * length * thickness".

- Q: What are the tapes for packing tape?

- There are many kinds: packing tape series: transparent adhesive tape, color adhesive tape

- Q: Flexo printing tape, what are the common, what are the advantages and disadvantages?

- (3) when pasting the plate, the area of the adhesive tape should be larger than the area of the printing plate. That is to say, the edge of the adhesive tape should be larger than the edge of the printing plate. EPSON will greatly reduce the risk of the warped version.(4) when printing, the interface of the printing plate should avoid the interface of the adhesive tape. If the interface of the printing plate is facing the interface of the adhesive tape, it will lead to the sticking of the printing plate at the interface.(5) in a printing plate cylinder or sleeve surface mount tape, recommend the use of scraper instead of the hand rolled plate mounting tape printability, because it is relative to the hand operation, the scraper can put more pressure on the mounting tape so that mounting tape better stick to the printing plate or the sleeve surface, while effectively avoiding bubbles; in mounting tape stuck to the surface of the plate, with a soft rubber roller instead of rolling plate flexo, in order to better fit the drive plate, bubbles, protection plate surface fine mesh point.

- Q: What are the considerations for using packaging tape on glossy surfaces?

- When it comes to using packaging tape on glossy surfaces, it's important to keep a few key things in mind. First and foremost, the smoothness and slickness of the glossy surface can affect how well the tape sticks. The glossy finish creates a barrier that can make it difficult for the tape to adhere securely. That's why it's crucial to make sure the surface is clean and free from any dirt, oils, or residue that could prevent the tape from sticking properly. Choosing the right type of packaging tape is also important. Opting for a tape specifically designed for glossy surfaces, like high tack or acrylic adhesive tapes, can provide better adhesion and last longer. These tapes are specially formulated to stick well to smooth surfaces and create stronger bonds compared to regular packaging tape. It's also a good idea to test the tape on a small, inconspicuous area of the glossy surface before applying it everywhere. This will let you see how well the tape sticks and ensure that it doesn't leave any residue or damage the glossy finish when you remove it. Temperature and environmental conditions should also be taken into consideration. Extreme heat or cold can affect how well the tape performs on glossy surfaces. For example, high temperatures can cause the adhesive to soften, leading to the tape failing, while cold temperatures can make the tape more brittle and prone to peeling. Lastly, it's crucial to handle the glossy surface with care to avoid leaving fingerprints, smudges, or scratches that could detract from its appearance. Wearing gloves or using protective films can help prevent these issues. By keeping these factors in mind, you can enhance the effectiveness and reliability of packaging tape on glossy surfaces, ensuring that your packages are securely sealed without compromising the glossy finish's aesthetic appeal.

Send your message to us

Polypropylene Packaging Tape Wide 19mm*9m Insulating Tape Color 5 Rolls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords