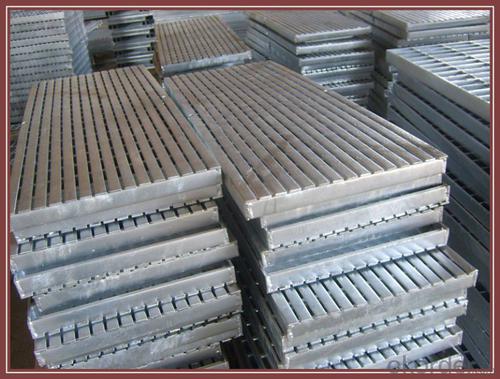

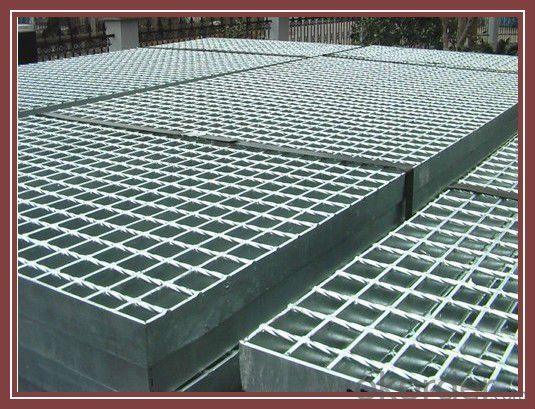

Zinc Aluminum Outdoor Aluminum Alloy Gratings Manhole Cover/Srain Trench Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do you prevent surface marring of aluminum sheets during handling?

- To prevent surface marring of aluminum sheets during handling, there are several steps you can take: 1. Use clean gloves or finger cots: When handling aluminum sheets, it is important to avoid direct contact with bare hands as they may contain oils, dirt, or other contaminants that can leave marks on the surface. Wearing clean gloves or finger cots can provide a barrier and prevent any transfer of substances onto the sheets. 2. Use protective packaging: Prior to handling, consider using protective packaging such as foam or plastic sheets to cover the surface of the aluminum sheets. This will provide an additional layer of protection against scratches or abrasions during transportation or storage. 3. Implement proper storage and handling techniques: Store aluminum sheets in a clean and dry environment, away from any abrasive materials or surfaces. When moving or handling the sheets, ensure that they are lifted or supported evenly to avoid any bending or distortion that may lead to surface marring. Using appropriate lifting equipment, such as suction cups or clamps, can help distribute the weight evenly and minimize the risk of damage. 4. Clean the surface regularly: Regularly clean the aluminum sheets using a mild detergent or aluminum-specific cleaning solution. This will help remove any dirt, grime, or other substances that could potentially cause surface marring. Be sure to use soft, non-abrasive cleaning tools such as microfiber cloths or sponges to avoid scratching the surface. 5. Implement quality control measures: Establishing quality control measures during the handling process can help identify any potential sources of surface marring. Regular inspections should be conducted to check for any signs of damage or defects. Implementing proper training for employees involved in the handling process can also help minimize the risk of surface marring. By following these preventive measures, you can significantly reduce the chances of surface marring on aluminum sheets during handling, ensuring their pristine condition and quality.

- Q: Is it possible to use aluminum sheets as a material for exterior wall cladding?

- <p>Yes, aluminum sheets are commonly used for exterior wall cladding due to their durability, low maintenance, and resistance to weather conditions. They are lightweight, easy to install, and can be recycled, making them an environmentally friendly option. Aluminum sheets can also be painted or coated in various colors and finishes, offering design flexibility. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the integrity of the cladding system.</p>

- Q: How do you prevent distortion of aluminum sheets during welding?

- To prevent distortion during the welding of aluminum sheets, there are several important steps that can be taken: 1. It is crucial to properly prepare the joint by cleaning and beveling the edges of the aluminum sheets. This will ensure a better fit-up and reduce the likelihood of distortion. 2. The use of appropriate fixtures and clamps to hold the aluminum sheets in place during welding can help distribute the heat evenly and prevent movement or buckling. This will minimize the risk of distortion caused by thermal expansion. 3. Tack welding can be done at regular intervals along the joint before performing a full weld. This temporarily secures the sheets and allows for controlled cooling, reducing distortion. 4. Following a proper welding sequence is also beneficial. Starting from the center and gradually moving towards the edges, alternating between sides, helps balance the heat input and allows for cooling between welds, minimizing distortion. 5. Preheating the material before welding can help reduce the temperature gradient and minimize distortion for thicker aluminum sheets. Post-weld heat treatment can also be applied to relieve residual stresses and promote dimensional stability. 6. Employing appropriate welding techniques, such as lowering the heat input and using a slower travel speed, can help minimize distortion. Using a smaller weld bead size and avoiding excessive weaving also control the heat input and reduce distortion. 7. It is crucial to ensure that the welding parameters, such as voltage, current, and wire feed speed, are correctly set and maintained. Using the appropriate parameters for the specific aluminum alloy being welded will result in a more controlled heat input, reducing distortion. By implementing these preventive measures, the risk of distortion during aluminum sheet welding can be significantly reduced, leading to improved weld quality and dimensional stability.

- Q: How does the surface finish affect the optical properties of aluminum sheet?

- The optical properties of aluminum sheet are significantly influenced by its surface finish. Optimal light reflection and minimal scattering are achieved with a smooth surface finish, leading to heightened reflectivity. Consequently, this amplifies the brightness and reflectiveness of the aluminum sheet. Conversely, a rough or textured surface finish on aluminum sheet provokes light scattering in various directions, thereby diminishing reflectivity. Consequently, this yields a lackluster and less reflective appearance. Furthermore, the surface finish has an impact on the visual aspect of any coatings or films applied to the aluminum sheet. A smooth surface finish promotes superior adhesion and uniformity of coatings, thus augmenting their optical properties. To conclude, the optical properties of aluminum sheet are improved with a smooth surface finish, as it enhances reflectivity and diminishes scattering, ultimately resulting in a more vibrant and reflective appearance.

- Q: Can aluminum sheets be used for decorative wall panels?

- Aluminum sheets are indeed suitable for decorative wall panels. As a versatile material, aluminum offers a wide array of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it perfect for both indoor and outdoor applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for limitless design possibilities. Moreover, aluminum can be enhanced in appearance and provided with extra protection against wear and tear through powder-coating or anodizing. Whether it's for residential or commercial spaces, aluminum sheets can impart a modern and stylish touch to any wall, rendering them a highly sought-after choice for decorative wall panels.

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- You are not eating the aluminum foil when wrap food in it to cook. There is little transference of aluminum to the food you eat. When using it for baked potatoes, the skins just slide off so the potato meat itself had not contact with the foil. Though I have also read something on the use of aluminum cooking vessels and aluminum foil having some properties that can be dangerous to our health, I could find no articles from the FDA or other such qualified organizations regarding the use of aluminum foil.

- Q: The radius of an atom of aluminum is 143pm and there are 10^12 in a meter. The aluminum is a 3x3cm square. The density is 2.70 g/cm^3. I found the mass to be 0.03g. I found the volume to be 0.09cm^3

- Good quality standard aluminum foil such as Reynolds brand is 0.007 inches thick. If aluminum atoms are indeed 143 picometers in radius then the foil would be 2,486,713 atoms thick. Of course, the thickness is not controlled to a tolerance of one atom. (Cheaper brands are about 0.0060 to 0.0065 inches thick.) The ionic radius of aluminum is commonly accepted to be 72 pm, and as of 2008 a covalent radius of 121 pm. . .

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- This Site Might Help You. RE: Steel or aluminum alloy rims? Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100. Should I take it? Or just stick...

- Q: Can aluminum sheets be used for sign making?

- Yes, aluminum sheets can be used for sign making. Aluminum is a popular choice in the sign making industry due to its durability, lightweight nature, and resistance to corrosion. It can be easily cut and shaped into various sizes and designs, making it versatile for different types of signs. Additionally, aluminum sheets can be painted or coated with vinyl graphics to enhance their visual appeal and make them more eye-catching. Overall, aluminum sheets are a reliable and cost-effective option for creating high-quality and long-lasting signs.

- Q: Can aluminum sheets be painted or coated with different colors?

- Aluminum sheets are capable of being painted or coated in a variety of colors. The versatility of aluminum as a material makes it easy to achieve the desired aesthetic through painting or coating. To paint or coat aluminum, a layer of paint or coating material is applied onto the sheet's surface. This can be accomplished through spraying, rolling, or dipping methods. The paint or coating adheres to the aluminum, creating a protective layer while altering its color or finish. The ability to paint or coat aluminum sheets in different colors provides limitless opportunities for customization and design possibilities.

Send your message to us

Zinc Aluminum Outdoor Aluminum Alloy Gratings Manhole Cover/Srain Trench Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords