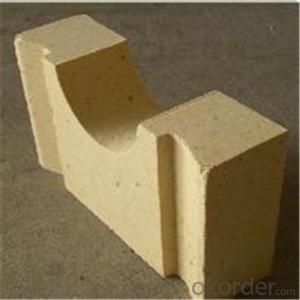

Zero Thermal Expansion Refractory Silica Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

High Purity 99% SiO2, extremely low thermal expansion coefficient which makes them ideal for use as a hot repair material, as a hot repair material (for glass melters and coke oven plants)

We are a pioneer of refractory for maintenance of furnaces, kilns, etc. From our foundation, we has developed lots of new refractory products and applied innovative technologies to extend furnace/kiln service life and increase productivity in a wide range of industries, mainly in ironmaking, coking, metallurgy,glassmaking industries in the past few years.

Product A: Fused Silica Brick

Brand: ZES-95H

Shape: We can manufacture very large blocks, as well as very complex shape

Property:

1. Excellent thermal shock resistance

2. Near zero expansion coefficient

3. Only very few cristobalite transformation for long service of coke oven

4. Reliable This product was developed by the founder of our company, and has been applied

In coke ovens of BAOSTEEL for more than 10 years without any problem

Product B: Fused Silica Brick

Brand: ZES-99

Shape: We can manufacture very large blocks, as well as very complex shape

Property:

1. Excellent thermal shock resistance

2. Near zero expansion coefficient

3. No long term drying oven required; No preheating required

4. Superior chemical and physical properties:

4.1 High Refractoriness under Load 1680 centigrade degree

4.2 Low creep

You are welcome to contact me for details:

Photos for Packing

- Q: Physical solid waste disposal

- Reduce crack production and improve yield. The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Acidic materialMainly siliceous materials, such as quartz, tridymite and cristobalite, chalcedony, flint, opal, white quartzite, silica sand, diatomaceous earth, silicon oxide contained in these siliceous materials (SiO2) at least 90%, pure raw materials are silicon oxide as high as 99% or more. Siliceous materials at high temperature is the acidic nature of chemical dynamics, when the presence of metal oxide, or when in contact with the chemical reaction, and combined with a fusible silicate. Therefore, if there is a small amount of metal oxide in siliceous material, it will seriously affect its thermal resistance.

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: What is acid refractory?

- Refractory materials are mainly quartz glass products, combined with fused quartz products, silica brick and unshaped refractories. Semi siliceous refractory materials are generally attributed to this category. As for fireclay refractories, they are also classified as semi acidic or weakly acidic refractories. Also, zircon refractory and silicon carbide refractory for special acidic refractory materials are also classified into this category.

- Q: How much is the highest melting point of silicon?

- Mainly used for partition, carbonization chamber of coke oven and combustion chamber open hearth furnace regenerator and a sediment chamber, soaking furnace, glass melting furnace refractories and ceramic kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace

- Q: What role does silica play in refractories?

- Low fractory refers to the alumina content between 10%~30%, SiO2 content is less than 85%, semisilica brick SiO2 = 65%,The SiO2 content of not less than 93%, refractory material to natural quartz rock as the main raw materials are called silica, silica brick, silica brick, quartz glass and special products. China's literature generally put this type of product is called "siliceous refractory products", which is the most important brick.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- The scale quartz is a spear shaped double crystal structure, very compact and favorable to the increase of thermal conductivity. The high thermal conductivity of silica brick in improving thermal conductivity and other performance indicators and traditional coke silicabrick agreement.That is to say, the high thermal conductivity of silica brick all inherited the traditional advantages of coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Can generate the material needs is the best way to see the impurity problem!! the first consideration is whether can get the material impurities with what method choice after the time! Miscellaneous reactions cannot have new impurity formation! Selected cannot and need material reaction reagent!

- Q: Such purpose and scope please give me detailed points thank you

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

Send your message to us

Zero Thermal Expansion Refractory Silica Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords