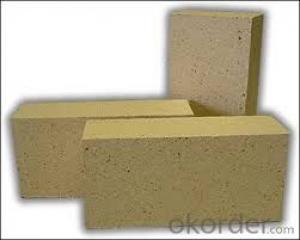

High Alumina Silica Refractory Bricks for Electric Arc Furnace Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Alumina-silica Refractory Bricks Used In Electric Arc Furnace Roof4

Manufacture

Low price.

Looking for lo

Alumina-silica Refractory Bricks Used In Electric Arc Furnace Roof

Here we can help you find the most suitable one to meet your needs.

No waste! No extra cost! No cheat! All we are doing is trying to save your cost!

We can't say we are No.1 in China, but we are trying to be the No.I in mind of our clients!

If you are interested in this kinds of products,welcome view our website. high temperature insulating bricks

All I want to tell you is:please have a "taste",just like as taste a cup of coffee, talk with our sales,then you'll know whether we are your idea supplier or not.

All of your inquiry will be attentioned promptly!

the follows are some detail parameters of our products,in order to save your time,we just show you the datas

fire clay brick for various kilns

Characteristics:

Fireclay brick is made from clinker clay by mixing, forming, drying, sintering and matching characterized by good resistance to corrosion and abrasion, good thermal shock resistance, good spelling resistance, high mechanical strength, good volume stability under high temperature.

Specifications

1. for Glass Melting Furnace

2. High quality and best price

3. Chemical stability

4. ISO9001:2000

5. Timely deliver

Applications: Metallurgy, building materials, chemical industry, petroleum, machinery manufacturing, silicate, power and other industries.

Physical andChemical Indicators:

Items | Index | ||||||||

N-1 | N-2a | N-2b | N-3a | N-3b | N-4 | N-5 | N-6 | ||

Refractoriness, °C ≥ | 1750 | 1730 | 1730 | 1710 | 1710 | 1690 | 1670 | 1580 | |

Refractoriness Under Load,°C, [0.2MPa×0.6%] ≥ | 1400 | 1350 | -- | 1320 | -- | 1300 | -- | -- | |

Linear Change on Rehearting,% | 1400°C×2h | +0.1 -0.4 | +0.1 -0.5 | +0.2 -0.5 | -- | -- | -- | -- | -- |

1350°C×2h | -- | -- | -- | +0.2 -0.5 | +0.2 -0.5 | +0.2 -0.5 | +0.2 -0.5 | -- | |

Apparent Porosity, % ≤ | 22 | 26 | 24 | 24 | 26 | 24 | 26 | 28 | |

30.0 | 20.0 | 25.0 | 20.0 | 15.0 | 20.0 | 15.0 | 15.0 | ||

- Q: What refractory material does cupola lining use?

- It's made of high quality refractory material: 1770 ~ 2000 centigrade.

- Q: What is the price of the latest thermal insulation material?

- Also through online pre understand the products and prices, and now have large-scale manufacturers are generally opened on the cable business. Goods than three, manufacturers on-site inspection, confirm the quality of goods after considering cooperation.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- The brick Pei boring and time. 6, Pei brick kiln installed between the brick and the brick Pei order, Pei and kiln top, kiln wall gap etc.. 7, high alumina brick kiln plan, and the lack of edges and corners of the scene should be avoided.

- Q: Density of high alumina bricks

- Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: Can high alumina brick resist carburizing?

- The resistance to carburization is not directly related to the bulk density of bricks

- Q: What are the requirements for refractory materials in heat treatment furnace?

- The structural strength of high temperature is evaluated by loading softening point. Load softening point is that under certain pressure (2 kg/ cm 2 = 0.2MPa) under the condition of heating rate to heating, measured the sample deformation (deformation for the original sample 0.6%) temperature. This temperature is called the softening point of the refractory. Sample size is Phi 36 x 50mm.

- Q: What is the apparent porosity of high alumina brick?

- In the production of high alumina bricks in addition to the entity, there are many different sizes and shapes of different pores, pores can be divided into three categories: one side closed the other side and the outside world is called open pores, closed in the product not communicated with the outside is called closed pores, penetrating through pores called the few products.

- Q: How are the grades of high alumina bricks differentiated?

- If the content of Al2O3 is higher than 90%, it is called corundum brick. Because of the different resources, the standards of different countries are not exactly the sameFor example, European countries limit the content of Al2O3 for high alumina refractory materials at 42%.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- Generally, the thermal shock resistance of high alumina brick products is worse than that of clay brick products

Send your message to us

High Alumina Silica Refractory Bricks for Electric Arc Furnace Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords