High Alumina Straight Refractory Bricks with Low Thermal Conductivity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High Alumina Refractory Bricks AL7 Low Thermal Conductivity

Straight Refractory Bricks Low Thermal Conductivity

Brief discription for Straight Refractory Bricks

CMAX Straight Refractory Bricks are classified according to alumina content ranging from 48% to 90%.

CMAX Straight Refractory Bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for Straight Refractory Bricks

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for Straight Refractory Bricks

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

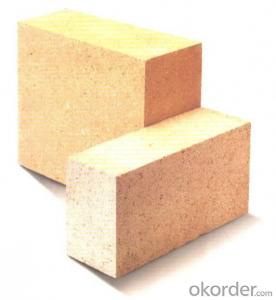

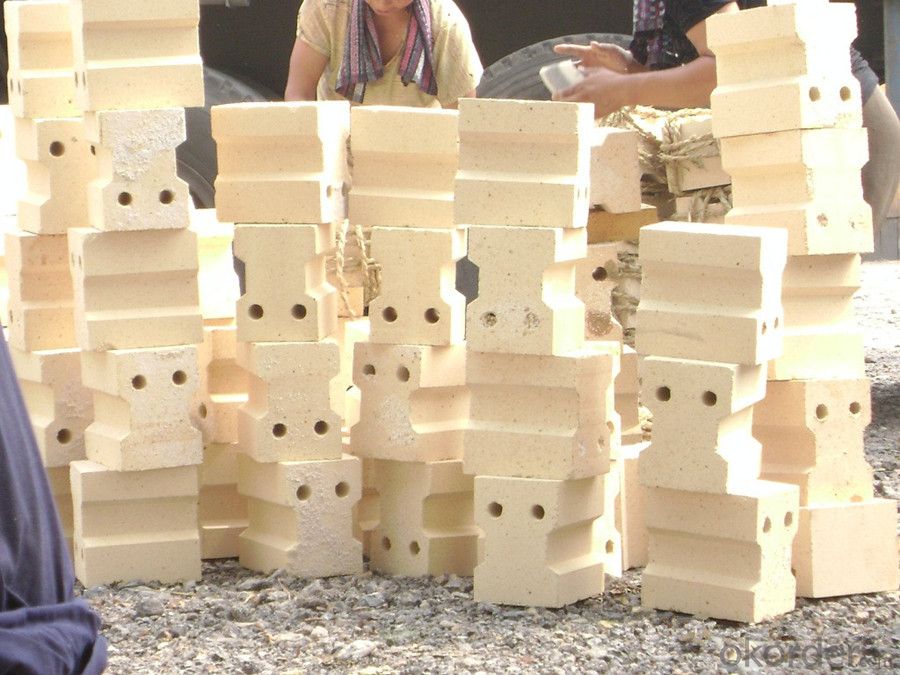

Images/photographs for Straight Refractory Bricks

◆ breif images-different shape for different usage

◆ Packaging for refractory bricks

◆ Producing Equipment for refractory bricks

◆ Testing Mashines for high alumina bricks

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: What is the price of the latest thermal insulation material?

- Also through online pre understand the products and prices, and now have large-scale manufacturers are generally opened on the cable business. Goods than three, manufacturers on-site inspection, confirm the quality of goods after considering cooperation.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- Quality requirements for aluminium bricks of different grade. 2, high aluminum powder and high alumina aggregate and other materials of reasonable proportion, to reach the production requirements.

- Q: How many cubic bricks does a high alumina brick have?

- Different content of aluminum, different proportion, weight is not the same. General grade T3 standard brick, 4.3~4.5kg, aluminium content 75. T3 size 230*114*65mm.

- Q: How are the high alumina bricks fired?

- Light and high alumina bricks are usually fired in a weak oxidizing atmosphere. In light and high alumina bricks firing, they are often rich in impurities such as R2O, RO, Fe2O3 and so on. They react with Al2O3 and SiO2 at high temperature to produce liquid phase. In the Al2O3 - SiO2 - R2O system, the growth rate of liquid phase increases with the increase of temperature at high temperature. So, because the increase of sintering temperature brings a lot of liquid phase, the decrease of liquid viscosity will lead to the deformation of brick and the decline of brick high temperature function. Therefore, the lower sintering temperature and longer holding time should be adopted in the sintering process dominated by liquid phase sintering. The production practice shows that the same firing temperature can be used for the high grade aluminum bricks. When fired in an inverted flame kiln, it is usually 1430 degrees centigrade and insulated by 40H. The high alumina bricks such as Ill are 1390~1420 degrees centigrade. When the tunnel kiln is fired, they are 1550 and 1450~1500 degrees centigrade respectively. High alumina brick is usually made of weak oxidizing atmosphere.

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- If the condition, the user heat-resistant steel welding grip nails, expansion joints can not be too big.. Also to use high temperature aluminum brick, high temperature resistance, but also to extend its use cycle.

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Semisilica brick: the content of Al2O3 is 15% ~ 30% of aluminium silicate refractory products. Manufacturing products are semi silica quartz containing impurities or native clay kaolin, refractory clay or kaolin beneficiation tailings and the pyrophyllite

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- Low creep and high alumina brick is based on the theory of "three stones". The combination of bauxite and clay as the main raw material, adding kyanite, andalusite and sillimanite, commonly known as the "three stone" control, physicochemical index and size composition, using alumina mullite corundum + + raw materials such as technical scheme. In the production process, first to detect and control indexes of raw materials, crushing, grinding, sieving process, according to the distribution ratio of ingredients, the size and moisture control of mud mixing after to meet the requirements of forming and molding machine, the use of qualified abrasives, blow molding control number, size and flash at the same time, the detection efficiency of semi-finished products and meet the requirements. Production process: high temperature calcination of high-grade alumina, adding small creep rate of high temperature materials, by high-pressure molding and high temperature firing. It has the characteristics of high strength, low creep rate and high use temperature. Widely used in high temperature furnace, hot air furnace hearth lining, brick and so on.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: How to reduce porosity of high alumina brick

- High alumina brick used as refractory products in refractory material, has a great application in masonry kilns, insiders pointed out that the quality of high alumina brick general porosity and it has a great relationship! So, how to reduce the porosity of high alumina brick rate is very important!

- Q: Is glass wool inorganic thermal insulation material?

- The use of glass wool, glass wool is usually used as raw materials of various types of insulation materials, such as glass wool board, glass wool, glass wool, glass wool pipe, can be used in the following areas:1) roof insulation, cold protection, sound-absorbing materials; 2) building exterior wall insulation and cold protection; 3) entertainment places, theaters, television stations, radio stations, laboratories, sound absorption treatment.

Send your message to us

High Alumina Straight Refractory Bricks with Low Thermal Conductivity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords