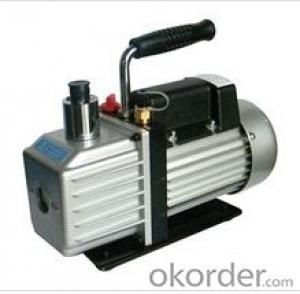

YHZKB-2XZ series rotary vane vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

2XZ-BSeries

1. High speed, Iow volume, light weight, equipped with noise reducer, low noise, less shake. Pump stop and oil returnprevention is equipped, so that pupm oil is prevented to get back to the pump once pump stopped working, which makes it easy to restart.2. Gas valve is installed in order to separate the vapor from the gas, when pumping gas mixed with vapor. The valve prohibited the entrance of the vapor, ensured the purity and prolonged the use of the pump oil.3. Vent is applied with oil fog capture mchine to eliminate oil fog when discharge the gas. Ol collecting equipment is installed around the oil sal, in order to preven oil leaking, and entironment pollution.Motor power:0.37~1.5KW,extract capacity2~15L/S,Limit vacuum:2×10-2Pa。

■List of performance |

| Unit | 2XZ-2B | 2XZ-4B | 2XZ-6B | 2XZ-8B | 2XZ-15B | |

off-gas quick result | L/S | 2 | 4 | 6 | 8 | 15 | |

limited pressure | Branch pressure (close gas) | Pa | 2×10-2 | 2×10-2 | 2×10-2 | 2×10-2 | 2×10-2 |

General pressure (close gas) | Pa | 6×10-1 | 6×10-1 | 6×10-1 | 6×10-1 | 6×10-1 | |

Branch pressure (open gas) | Pa | 6×10-1 | 6×10-1 | 6×10-1 | 6×10-1 | 6×10-1 | |

General pressuer (open gas) | Pa | 9×10-1 | 9×10-1 | 9×10-1 | 9×10-1 | 9×10-1 | |

Noise (close gas) | dB(A) | 60 | 60 | 65 | 70 | 70 | |

Working temperature | ℃ | 80 | 80 | 80 | 85 | 85 | |

electric machine | Voltage | V | 380/220 | 380/220 | 380/220 | 220/380 | 220/380 |

Power | Kw | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | |

Rotate speed | r/min | 1420 | 1420 | 1420 | 1400 | 1400 | |

Weight | Kg | 23 | 30 | 40 | 70 | 90 | |

Shape&size (L×W×H) | mm | 560×190×230 | 570×190×230 | 570×190×230 | 600×230×420 | 690×230×420 | |

- Q: Working principle and diagram of axial piston pump with pressure compensation variable

- Working principleThe main part (see section structure) the transmission shaft drives the rotating cylinder, the plunger seven uniform distribution on the cylinder to rotate around the shaft center line through the center of the spring will be slippery boots column components in the variable pressure in the head (or swash plate). In this way, with the rotation of the plunger cylinder for reciprocating motion complete, oil absorption and oil pressure action.

- Q: How can the submersible pump level meter be connected?

- Installation of submersible pumps dedicated liquid level float, connected to the submersible pump power line (some submersible pumps bought with), or received submersible pump control circuit, high starting, low stop.

- Q: Must the water pump in the tank be all soaked in water?

- Of course, if the motor is overheated, it will burn, and the temperature of the water will drop down.

- Q: How to select metering pump head?

- The main index affecting the selection of the pump head is the composition of the medium to be transported and added, as well as the pressure and the temperature of the external environment

- Q: What are the application areas of pumps?

- Performance range from the pump to see giant pump flow up to hundreds of thousands of cubic meters per hour, while the micro pump flow per hour in a few milliliters; pump from atmospheric pressure up to 19.61Mpa (200kgf/cm2); the lowest temperature of the liquid is transported up to -200 DEG C, up to 800 DEG C. Pumps carry a wide variety of fluids, such as water (clean water, sewage, etc.), oils, acid and alkaline solutions, suspensions, and liquid metals.In the chemical and oil sector production, raw materials, semi-finished products and finished products are mostly liquid, and semi-finished and finished products to raw materials, need to go through a complex process, to pump and provide transportation of liquid chemical reaction of the pressure and flow in the process, in addition, the device also used in many pumps to adjust the temperature.In agricultural production, the pump is the main irrigation and drainage machinery. Rural areas in our country are vast and vast, and a large number of pumps are needed every year in rural areas. Generally speaking, agricultural pumps account for more than half of the total output of pumps.Pumps are also the most widely used equipment in the mining and metallurgical industries. The mine needs pumping and drainage. In the process of ore dressing, smelting and rolling, the pump needs water to supply water first.

- Q: What are the basic technical parameters of the pump?

- Two, pump head H head is the unit weight of the liquid pump pumping from the inlet of the pump (pump inlet flange) to the outlet of the pump (pump outlet flange) energy value. Effective energy is a Newtonian liquid through the pump unit is obtained. The N m/N=m, the height of liquid column pumping liquid. Habits referred to as meters. Three, the pump speed is n RPM pump unit time revolutions, represented by the symbol n, the unit is r/min. four, the pump NPSH NPSH NPSH is also called net positive suction head, said main parameters of cavitation performance. Cavitation has been used a h power of five, the power of the pump. And the efficiency of the pump is usually refers to the input power, which is the prime mover on the pump shaft power, it is also known as the shaft power, denoted by P;

- Q: Rules for operation of centrifugal pumps

- 5, before you stop, you should gradually close the outlet valve, then turn off the power supply.6, with the check valve line, in ensuring the check valve intact, without closing the outlet valve, check the pump cavity, no air can be directly switched on.

- Q: What is the working pressure of the hydraulic pump in the hydraulic transmission system?

- The choice of pressure depends on the size of the load and the type of equipment. Consideration shall also be given to the assembly space, the economic conditions and the availability of components for the actuators.In the case of a certain load, low working pressure, is bound to increase the structure size of the actuator on some devices, the size must be limited, from the perspective of material consumption is not the economy; on the other hand, the pressure to choose too large, the pump, cylinder, valve and other components of the material, sealing and manufacturing accuracy requirements very high, must raise the cost of equipment.

- Q: What should be used to pay attention to the use of mechanical pumps?

- There are many kinds of pumps, such as centrifugal pumps, piston pumps, diaphragm pumps, vane pumps, gear pumps, etc.

- Q: Why is the submersible pump tripped on an electrical switch?There is no electrical leakage protection, directly connected to the circuit breaker, and when the switch on, the circuit breaker jumpedI checked the line is good, the pump did not break down, is not the water pump?

- There should be the following reasons: 1) the setting value of the trip switch is too small, and the operating current of the submersible pump exceeds its setting value, and the switch is tripped

Send your message to us

YHZKB-2XZ series rotary vane vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords