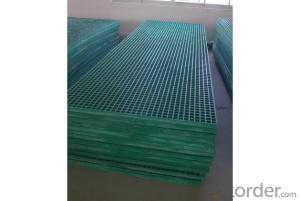

FRP Pultrusion Profiles Yellow Color FRP Gratings for Walkway

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description of FRP Grating

FRP Grating, Molded FRP Grating, Fiberglass Grating, GRP Grating,GRP Molded Grating,FRP Pultrusion Grating, FRP Mini Mesh Grating,Trench Grating, Drain Grating,Grating Walkway, Platform Grating...

Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

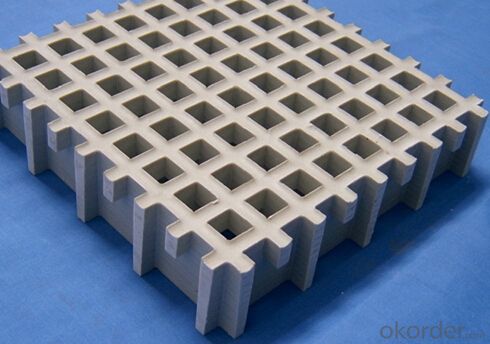

Specification of FRP Grating

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Payment terms?

We can accept L/C, T/T etc.

- Q: Can not use glass steel support column, the main support for the door

- The epoxy pultruded glass steel section is of high strength and can meet your requirement. You can choose the required section according to your requirement

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemical spills or leaks. The combination of the fiberglass reinforcement and the polymer matrix used in FRP pultrusion provides excellent resistance to a wide range of chemicals, acids, and corrosive substances. This makes FRP pultrusion profiles a suitable choice for applications where chemical resistance is crucial, such as in chemical processing plants, wastewater treatment facilities, and storage tanks.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to wear and abrasion. The combination of the reinforcing fibers, typically glass or carbon, and the plastic resin matrix creates a material that is incredibly durable and can withstand heavy usage. The pultrusion process also ensures a homogeneous structure with fibers evenly distributed throughout the profile, further enhancing its resistance to wear and abrasion. Additionally, FRP pultrusion profiles can be engineered with specific additives or surface treatments to further enhance their resistance to wear and abrasion, making them suitable for a wide range of applications in various industries, such as construction, transportation, and marine.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP pultrusion profiles can be used in electrical or telecommunications applications. FRP (Fiber Reinforced Polymer) pultrusion profiles have excellent electrical insulation properties and are resistant to corrosion, making them suitable for use in electrical and telecommunications infrastructure. Additionally, their light weight, high strength, and design flexibility make them a desirable choice for applications such as cable trays, support structures, and enclosures in these industries.

- Q: Are FRP pultrusion profiles resistant to caustic solutions?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to caustic solutions. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion provide excellent chemical resistance. Caustic solutions, such as strong alkaline substances, can often corrode or degrade traditional materials like steel or wood. However, FRP pultrusion profiles are highly resistant to chemical attack, making them suitable for applications where exposure to caustic solutions is common. This resistance makes FRP pultrusion profiles an ideal choice for industries such as chemical processing, wastewater treatment, and marine environments where corrosive substances are present. Nonetheless, it is important to consult the manufacturer's specifications and guidelines to ensure that specific caustic solutions are compatible with the particular FRP pultrusion profile being used.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- FRP pultrusion profiles possess remarkable resistance to moisture absorption, primarily due to the composition of the materials used in their construction. These profiles typically consist of a combination of fiberglass and resin, wherein fiberglass is naturally non-porous and impervious to moisture, while the resin is specifically designed to repel moisture. The moisture resistance of FRP profiles is further enhanced by the pultrusion manufacturing process. This process involves pulling the fiberglass and resin through a heated die, ensuring thorough impregnation of the fibers with resin and creating a dense and solid structure. Consequently, the resulting product exhibits exceptional resistance to water penetration and moisture absorption. Additionally, the moisture resistance of FRP pultrusion profiles can be augmented through the application of protective coatings or surface treatments, such as gel coats or UV-resistant finishes. These coatings provide an extra layer of defense against moisture ingress. The superior moisture resistance of FRP pultrusion profiles makes them an ideal choice for applications that involve exposure to water or high humidity, such as marine environments, wastewater treatment plants, or outdoor structures. By preventing issues like rot, rust, or degradation commonly associated with materials like wood or metal, these profiles offer a reliable and durable solution that can endure moisture exposure without compromising their structural integrity or performance.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- FRP pultrusion profiles are capable of being utilized in electrical insulation applications. They possess exceptional electrical insulation properties, rendering them appropriate for a broad range of electrical applications. The superior dielectric strength of FRP materials ensures the efficient containment of electrical currents within designated pathways, thus preventing leakage and electrical hazards. Moreover, FRP profiles exhibit low electrical conductivity, thereby decreasing the likelihood of electrical shorts and enhancing overall safety in electrical insulation applications. The non-magnetic characteristics of FRP materials are also advantageous as they eliminate the potential for electromagnetic interference (EMI) in sensitive electrical systems. Furthermore, FRP pultrusion profiles are lightweight, resistant to corrosion, and boast a lengthy operational lifespan. This renders them an economical and robust solution for electrical insulation applications.

- Q: Are pultruded FRP sections strong? What are its main areas of application?

- The tensile strength of products produced by pultrusion process is higher than that of ordinary steel.Widely used in transportation, electrical, electrical, electrical insulation, chemical, mining, marine, watercraft, corrosive environment and life, civil areas.

- Q: What types of materials are commonly used in FRP pultrusion?

- The manufacturing process of FRP pultrusion involves pulling continuous fibers through a resin bath and then through a heated die, resulting in a composite material with high strength and stiffness. Different types of materials are commonly used in FRP pultrusion, depending on the specific application and desired properties. 1. Fibers: Fiberglass (glass-reinforced polymer) and carbon fibers are the most commonly used in FRP pultrusion. Fiberglass is cost-effective, lightweight, and offers good strength and corrosion resistance. Carbon fibers, on the other hand, are more expensive but provide exceptional strength, stiffness, and lightweight properties. 2. Resins: The resin matrix used in FRP pultrusion provides rigidity and protection against environmental factors. Polyester resin is the most commonly used due to its low cost, ease of handling, and good mechanical properties. Vinyl ester resin is another popular choice, offering improved chemical resistance and heat tolerance compared to polyester. Epoxy resin is used when high strength and durability are required. 3. Additives: The resin matrix can be enhanced with various additives to improve specific properties of the FRP pultruded product. UV stabilizers are commonly used to protect against ultraviolet degradation. Flame retardants can be added to increase fire resistance. Other additives like pigments, fillers, and mold release agents may also be used to achieve desired aesthetics and processing characteristics. By selecting the appropriate combination of fibers, resins, and additives, FRP pultrusion can produce a wide range of composite materials with tailored properties to meet specific application requirements. This versatility in material selection is one of the key advantages of FRP pultrusion, making it suitable for industries such as construction, infrastructure, aerospace, automotive, and marine.

Send your message to us

FRP Pultrusion Profiles Yellow Color FRP Gratings for Walkway

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords