EASY-CLEANING PREPAINTED STEEL COIL FOR CHEMICAL ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

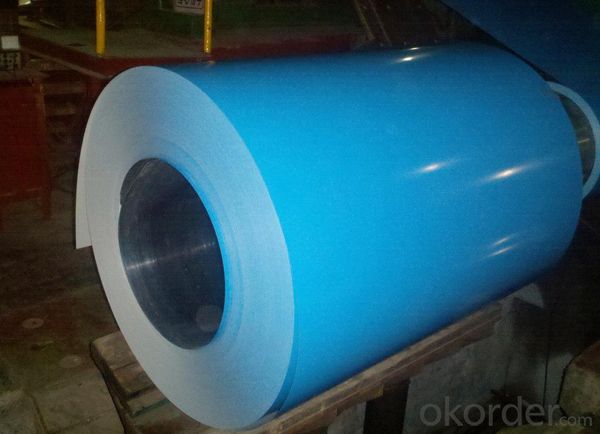

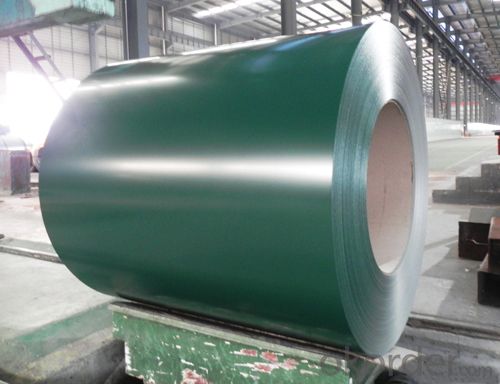

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: PVC sheet size how much the largest

- The main plate is the width, mainly 1.2 meters and 1.5 meters before the main, and now the widest can reach 2.8 or even 3 meters. As for the length is to see what you need, it is continuous production, according to your request cut.

- Q: Willow eucalyptus wood and pine which is good

- Although it is a relatively cheap wood, but the average price of pine is higher than the rice eucalyptus. Willow eucalyptus wood, because of its appearance (grain, scar), and the material itself is less valuable. Willow eucalyptus rarely used directly into furniture, and exposed wood finishes. And more as a blockboard and other man-made plate sandwich core material, and then blockboard all kinds of artificial wood paper, "camouflage" into a variety of good wood, and then made of furniture. Of course, this "camouflage plate" country is allowed, but the state also clearly stipulates that the blockboard is not a solid wood, the use of blockboard production of products can not be called solid wood products.

- Q: What are the plates of plate furniture?

- Shenyang Xia Ergran plate furniture factory: plate furniture plate furniture Shenyang plate furniture Shenyang plate furniture plate furniture manufacturers plate furniture manufacturers, their own look, very much.

- Q: It is good for plate of plate and plate of deer river

- Daya South use more, dew river with more, in the particleboard are similar, particleboard production process is very mature. To be more environmentally friendly is the German Ivy board. Now a kind of three to play the fir lacquered board, solid wood core material, can not do the fake, with the rest assured.

- Q: What is the HS code of the PVC sheet?

- 39202017.00 PVC board 39204300.90 recycled PVC board 39204300.90 PVC board 39204300.90 color PVC board 39204300.90 color printing PVC board 39204300.90 PVC PVC board 39204900.90 anti-static PVC board 39219090.00 color PVC board 39261000.00 PVC board clip 39269090.00 PVC board display stand

- Q: Now on the market E0 grade plate how? Now on the market E0 grade plate how?

- Environmental standards for the main categories: E0 level: the international top standard (formaldehyde emission ≤ 0.5mg / L), no smell, without any harm. E1 level: (formaldehyde release 0.5mg / I ~ 1.5mg / L), there will be pungent taste, although not strong, long living time, resistance decreased, away from this environment will reduce the symptoms. [2] E2 level: Chinese standard: E2 level (formaldehyde emission greater than 1.5mg / L) will have a strong pungent taste, living for a long time, will induce asthma, rhinitis and other diseases, not suitable for children living. More than E2: induced leukemia, not suitable for human habitation.

- Q: Why is the PTFE sheet so slippery?

- In the plastic commonly known as "plastic king" of the PTFE plate, with excellent chemical resistance, corrosion resistance, aging resistance, self-sealing, non-stick, non-scaling and other excellent performance. Applicable equipment: the reactor, storage tanks, valves and containers lining, gaskets and so on.

- Q: The most commonly used gas shielded welding consumables are certainly different from the material being welded. The silicon content and the manganese content in the wire are higher than those in the material. And the sulfur content inside the wire is much lower than the sulfur content of the base material being welded. Here, the role of silicon manganese is in the welding arc, in the welding bath for deoxidation of the chemical reaction, the other silicon manganese infiltration of the base metal can also improve the strength and plastic of the weld metal.

- The most commonly used gas shielded welding consumables are certainly different from the material being welded. The silicon content and the manganese content in the wire are higher than those in the material. And the sulfur content inside the wire is much lower than the sulfur content of the base material being welded. Here, the role of silicon manganese is in the welding arc, in the welding bath for deoxidation of the chemical reaction, the other silicon manganese infiltration of the base metal can also improve the strength and plastic of the weld metal. ??? The metallographic structure of the weld metal is generally a coarse tissue, which is very poor in mechanical properties. The structure of the base material to be welded is generally fibrous forged tissue, and the mechanical properties are much better. However, due to the weld metal into a certain amount of silicon manganese, the strength of plastic have been improved. In general, the weld metal is much better mechanical than the low carbon steel base metal.

- Q: Computer tables, two kinds of sheet: particleboard / melamine board MDF / fiber board which is better material? Thank you!

- MDF is a plant wood fiber as the main raw material, by the hot mill, pavement, hot forming and other processes made. MDF surface smooth and smooth, fine material, stable performance, the edge of a solid, and the decorative surface of the board is good. But the density of the board is less tolerant of moisture, and in contrast, the density of the clamping force of the board less than the particle board, screw tightening if the loose, because the density of the board is not high, it is difficult to fix. Particleboard is made of natural wood crushed into pellets, and then pressed by the adhesive, because the profile similar to honeycomb, so called particleboard, environmental protection coefficient is much higher than the density board. Many manufacturers produce furniture using particleboard, but also the main material of the cabinet. Particleboard surface is often rubbed with trimethylenediamine on both sides of the finish, the edge of the treatment and MDF appearance of the same, the use of special connection assembly, removable. So recommend particleboard.

Send your message to us

EASY-CLEANING PREPAINTED STEEL COIL FOR CHEMICAL ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords