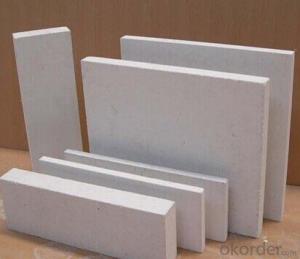

Decoration material magnesium oxide board/MGO board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | in bulk or wooden pallet |

| Delivery Detail: | 15 Days |

Specifications

high quality board with fireproof watweproof moisture proof sound proof and heatproof,easy installation durable and eco-friendly

Item | Detail |

Name | Magnesium oxide board, MGO board,glass magnesium board etc. |

Sizes | 2440*1220*(6-12)mm 2400*1200*(6-12)mm (Other size also are available.) |

Color | White and light gray |

Package | In bulk or wooden pallet |

Storage | In order to keep dryness in use ,please preserve inside room ,keep floor level and place wood board under it |

Features | 1. Fireproof: 2. Waterproof 3. Soundproof 4. Heat preservation 5. Environmental protection 6. Easy to install

|

Usage | Used primarily as fireproof materials for walls and ceilings in office buildings, apartment complexes, residential constructions, hotels, restaurants, railway stations, airports, scientific research institutions, schools, hospitals, and stadiums. It also can be used as an interlayer for building, movable partitions, sound-absorbing structures, sound insulation

|

| Standard | Result | ||

1 | Bending strength(Mpa) | ≥8.0 | 9.87 | |

2 | Impact strength(KJ/m2) | ≥1.5 | 4.51 | |

3 | Density(t/m3) | 0.7<p≤1.0 | 0.81 | |

4 | Impermeability | No droplets no damp | No droplets no damp | |

5 | Water content(%) | ≤8 | 2.9 | |

6 | Percentage of dry shrinkage(%) | ≤0.3 | 0.14 | |

7 | Percentage of water swelling(%) | ≤0.6 | 0.33 | |

8 | Screw-withdrawal force(N/mn) | ≥20 | 30.1 | |

9 | Content of chloride(%) | ≤10 | 7.70 | |

10 | Incombustibility (A garde) | Average exotherm in furnace(°C) | ≤50 | 2.6 |

|

| Fire duration(S) | ≤20 | 0 |

|

| Mass loss rate(%) | ≤50 | 48.7 |

11 | formaldehyde emission (mg/L) | ------ | <0.1 | |

Specifications

Fireproof Mgo board Perlite Panel

1.2400*1200mmSize

2.Density:950-1100kg/m3

3.light weight

4.Fireproof and moistureproof

DESCRIPTION

MgO board is made from Magnesium Oxide(MgO), Magnesium Chloride(Mgcl2), fiberglass mesh, sawdust, perlite etc.,using highly purified active MgO as the main fireproof material of board, high-quality MgCl2 as the main cementing material to solidify other materials, alkali-resistance fiberglass mesh to ensure the high strength of board, soft sawdust and light non-combustible perlite as filling materials.

It is a kind of Eco-friendly fireproof board widely used in construction and decoration.

(Pave slurry on the surface of MGO board to reduce the holes, make the surface more smoothness and less holes. Slurry paved board is a kind building material to further process.Suit to stick thin decorative material or paint on the board.)

APPLICATION

Partition and ceiling in the room, office building, hotel, hospital, airport, subway, gymnasium, library, museum, theater, factory building, computer laboratory, indoor natatorium. It is also used as the backing-lining, fireproof door and other wallboard, outdoor bill-board; base plate of various kinds of plaques; outside board of the ventilation shaft and the steel construction; roof boarding; electric wire and cable wraps up and applies etc.

- Q: How to maintain glasses glasses frames

- Glasses can be sent to the optical shop for ultrasonic cleaning, the general optical shop has this service. 1, tighten the screw: If the screws are loose, please get the glasses shop or yourself personally tighten, otherwise the glasses are easy to fall on the ground to break or scratched. 2, to keep clean: sweat or oil on the skin easy to corrode the metal part of the corrosive effect, cleaning glasses every day, to extend the life of the glasses very helpful. 3, the correct fold: most of the glasses are from the base side of the mirror gently folded, if the hard from the right first fold, will lead to the frame itself is not balanced, skewed, so you wear after the uncomfortable. 4, the correct mirror: wiping with a special cloth glasses. Do not touch the lens hard objects, do not wipe the lens with your fingers, please use a clean mirror cloth to wipe, reduce lens wear. 5, the correct storage: the front of the lens do not put down. If you do not, try to put glasses box, glasses, if not wear, please use a mirror cloth will be wrapped in glasses, into the mirror box, so as not to damage. 6, the right to wear: wear glasses with one hand, easy to make frame deformation. Frames if the variant, should find the local glasses master adjustment angle, do not adjust their own, so as not to break the lens, damage the frame. 7, to avoid the sun: a long time on the sun easy to place, because the frame in the light and thermal decomposition, easy to fade. Precautions: Correct care glasses will do: the lens should always wipe, the frame often care, glasses should always wear. Glasses are to help patients with myopia correction of vision tools, we have to correct care, not because of improper glasses and affect the effect of corrective vision.

- Q: What is the good dressing wardrobe plate?

- In the absence of economic considerations, it is recommended to choose a solid wood wardrobe. If the budget is not a lot, you can choose the plate wardrobe, and now the market is the mainstream plate is MDF and particle board, midline board easy to shape, you can make a lot of shape, more beautiful; you can go to China plate trading online to see.

- Q: What is the difference between the addition of the plate and the Eo grade plate?

- 1.E0 grade plate refers to the formaldehyde emission is less than or equal to 0.5mg / l of the plate products 2. No aldehyde addition refers to the absence of formaldehyde material added plate products, meaning no formaldehyde 3. To know the world does not absolutely contain formaldehyde products, even if there is no formaldehyde added to the wood comes with formaldehyde, but the content is very low harmless to the human body, like apples, beer, trees and so naturally contain their own formaldehyde

- Q: Willow eucalyptus wood and pine which is good

- Many businessmen will use cheap wood eucalyptus, Malacca (another produced from Southeast Asia fast-growing cheap wood) core wood blockboard beautification into a "solid wood ecological board", attempt and solid wood detached, confuse, mislead consumers, but its essence Is still the use of cheap wood man-made sheet. The price is there. Pine, especially New Zealand pine widely used in the production of a variety of pine wood furniture, there are many specialized in the production of pine furniture brand, is also widely used in children's furniture and other fields. In addition, we must use a lot of glue and increase the risk of formaldehyde release. The plate will also increase the release of formaldehyde during the cutting process, and the same conditions do not have these problems. Of course, the use of blockboard can save a lot of cost, so for decoration, props production, especially public commercial space project is still very meaningful. So in general, a kind of wood is not dare to show his face, a large square is made of solid wood furniture wood. Combined with the actual value of the two woods in reality, and their application effects. Pine should be excellent and willow eucalyptus wood, Malacca.

- Q: Do pcb circuit board which several kinds of plate

- Divided into two categories: rigid substrate materials and flexible substrate materials. Ordinary rigid substrate material is an important varieties of CCL. Copper brass board classification of a variety of ways. Generally, the reinforcing material of the plate is divided into five categories: paper base, glass fiber cloth base, composite base (CEM series), laminated multilayer plate base and extraordinary material base (ceramic, metal core base). If the board is adopted by the resin adhesive different classification, the common paper-based CCI. There are various types such as phenolic resin (XPc, XxxPC, FR-1, FR-2, etc.), epoxy resin (FE-3), polyester resin and the like. Common glass fiber cloth CCL has epoxy resin (FR-4, FR-5), which is the most widely used glass fiber cloth type. In addition, there are other extraordinary resin (glass fiber cloth, polyamide fiber, non-woven fabrics to increase the material): bismaleimide modified triazine resin (BT), polyimide resin (PI) , Diphenylene ether resin (PPO), maleic anhydride imide-styrene resin (MS), polycyclic ester resin, polyolefin resin, and the like. According to CCL flame retardant performance classification, can be divided into flame retardant (UL94 a VO, UL94 a V1 level) and non-flame retardant (UL94 a HB class) two types of boards. Nearly two years, with the environmental issues more attention, in the flame retardant CCL and separate a new non-brominated species of CCL species, can be called "green flame retardant cCL". With the rapid development of electronic products technology, the cCL has a higher performance requirements. Therefore, the performance classification from the CCL is divided into general performance CCL, low dielectric constant CCL, high heat resistance CCL (general plate L above 150 ℃), low thermal expansion coefficient CCL (generally used for packaging substrate ) And other types.

- Q: Plate formaldehyde content of the national standard ≤ 1.5mg / l is what it means

- Formaldehyde emission is less than 0.5mg, in line with the European E0 level standards; Formaldehyde emission is less than 1.5mg, in line with European E1 standard. China's current national standards for wood-based panel is E1 level, there is no E0 level of the so-called E0 level is the Japanese wood-based board substrate standards, which requires formaldehyde emission ≤ 0.5mg / L.

- Q: What is the meaning of C in 13.5 * 1500 * C in plate specifications?

- In front of the thickness and width, C said length, according to need to determine.

- Q: What is nothing in the wood terminology?

- The term "wood" refers to the branches that exist inside the trunk of the tree and its surface. Understand this point we can see that the so-called no-material, that is, no knots of wood. In fact, all the trees can not not long branches (palm and coconut trees and the like exception), but the branches are large, small, more, less, significant, hidden distinction Bale, so the real sense of no material is no of. In reality, any small or relatively subtle child (such as the hidden section, a few millimeters) can be ignored as no material. In general, the large trees from the ground to see the first branch of the trunk at that time, known as no material; also saw into a sheet or square material, the material is very small or no material, Said no material.

- Q: Ecological board and imported incense board which light fastness

- Ecological board and imported incense board which is more light, first of all we have to know that the ecological board is a man-made sheet, he is made of an environmentally friendly materials, and incense wood is a plate, from the light Aspect, it is certainly cooler wood.

- Q: My family smokers next to the installation of a natural gas using a firearm, the two appliances exhaust pipe close to the natural gas company in the safety inspection that is very dangerous, between the two exhaust pipe to use the same fire with fire Of the plate, but I do not know which type of plate to use, please know the answer. I am good to buy

- Fu Mei home fire board, you can go to the market to understand what

Send your message to us

Decoration material magnesium oxide board/MGO board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords