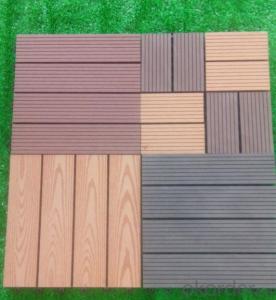

Wood Plastic Composite Decking DIY Tile Interlock Terrace WPC Decking Tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Engineered Flooring

Material | Vinyl plank + WPC core |

Dimension | 4”*36”, 6”*36”, 5”*48”, 6”*48”, 9”*48” etc. |

Thickness | 6mm, 7mm, 8mm, 10mm, 12mm, 15mm etc. |

Wear layer thickness | 0.15mm, 0.2mm, 0.3mm etc. |

Surface type | Embossed, handscraped, plain, skin |

Edge detail | Square edge, bevel edge |

Surface treatment | UV coating |

Base and middle layer | 100% virgin material |

Fiberglass | With or without |

Application | Home, office, hotel, bar, showroom etc. |

Certificates | CE, SGS, ISO9001 |

Main Features

Main Features

Main Features of Engineered Flooring

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

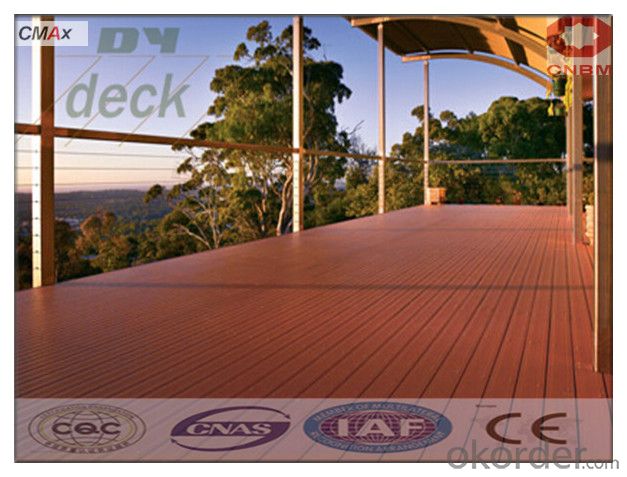

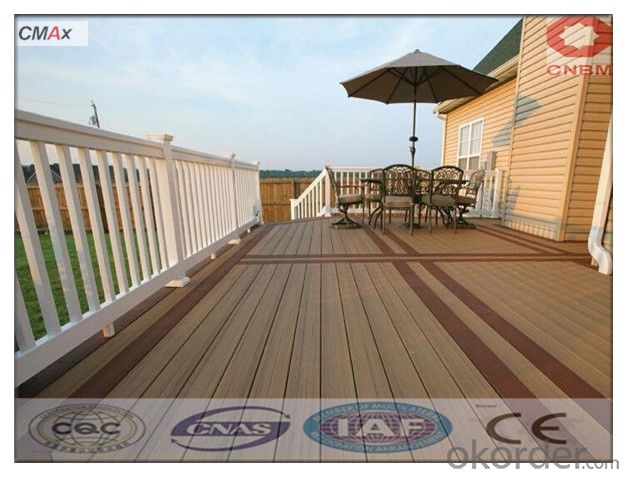

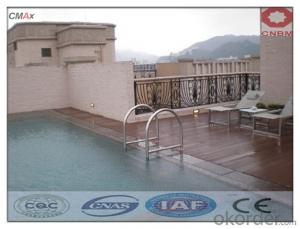

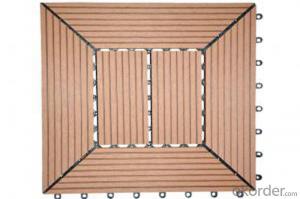

Picture show of Engineered Flooring

FAQ of Engineered Flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: How many square meters of composite floor

- OKorder Mall to check to see the price. Contrast, you should know the price of the.

- Q: Composite wood flooring

- Composite wood flooring with solid wood flooring and laminate flooring, solid wood flooring is divided into three layers of solid wood flooring and multi-layer parquet.

- Q: Can the composite floor be installed,

- Theoretically possible. Composite floor installation method 1. In the composite floor before the installation of the first check whether the door can be opened freely, if not, to the bottom of the door to a certain thickness, and then lay a layer of PVC over the ground film, so that can play a noise And the effect of moisture. 2. Place the first composite panel at the corner, the tongue and groove on the wall, with a wooden wedge leaving about 10mm of the expansion joints. 3. When installing the wall to the last board, take a full plate, place it in parallel with the previous tenon, set aside 10mm crossed on the wall end, install until the end of the line, if the remaining material length For 40cm, you can keep to the next line to use. 4. From the second line, the inside of the tongue and groove to be evenly coated with the floor of the special glue (the first line does not glue), the floor is fully installed, and then wet cloth or plastic scraper in time to spill the glue off. 5. Tighten the floor with a hammer and a wooden last. 6. After the first two lines, in a timely manner with a rope or ruler to calibrate. 7. left the last line of time, to take a piece of the whole board, on the already installed on the floor, up and down alignment, and then take another floor, on the board above, one end of the wall, and crossed, along the line Saw, this is the width of the floor required. Installed to the last line of the board, put the wood last block, the use of special fasteners will be squeezed into the floor, after installation 2 hours, the withdrawal of wood last.

- Q: Why is it better to use solid wood flooring?

- Why is it better to use solid wood flooring?

- Q: We're putting in an engineered floor in our kitchen and are trying to decide whether to staple or glue it down. There doesn't seem to be a preference from the manufacturer's information, just instructions on how to do either one.

- If you glue it, nothing will show, like staples.

- Q: Do you want to remove the original floor? Decoration company will take this little work? More

- There is no need to find a refurbishment company, buy the floor when you can ask how much labor, generally sell the floor can recommend the installation staff, you can need to remove the old floor requirements to tell the business, as long as the money, there will be installed workers willing to do of

- Q: Solid wood flooring really okay?

- This kind of floor is very good, but the market is good and bad, or to choose Kaopu, I personally recommend Santa on the floor, they do a good piece of this

- Q: what is engineered flooring?

- Engineered wood, or a flooring, is a structurally strong wood made up of 3 or 5 plys ( usually 3) of wood. Each ply is crossed and glued to each other. The top ply usually made of the wood or choice such as oak, maple, cherry etc. The pcs themselves are mill to exacting standards or engineered to precise standards. Usually thinner than solid wood, anywhere from a 1/4 to 5/8 thick. These flooring are made to be installed in several ways to fit many needs, such as stapled, glued,or made into a floating floor system. Any questions you can e mail me through my avatar. GL

- Q: Or solid wood (also see what the wood, such as two-winged beans, etc.), but the composite price is better, not easy to change, good care.

- Direct pavement on it!

- Q: Whether the wall can be horizontal slotted, can not be the words of the horizontal line should be set out of the rejection of Li Li Li Qingjiu how to leave the boat from where to go. My bedroom is not the ceiling so do not walk from the roof, I see there are a lot of said on the ground slot, do not know if this will destroy the wall. If you can slot the general open how deep the more secure. More

- Can be slotted, the general groove depth of 3-4 cm, is a conventional construction, does not affect the housing structure, the wall can be horizontal, horizontal and no limit

Send your message to us

Wood Plastic Composite Decking DIY Tile Interlock Terrace WPC Decking Tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords