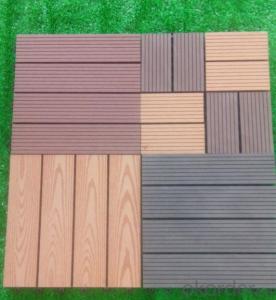

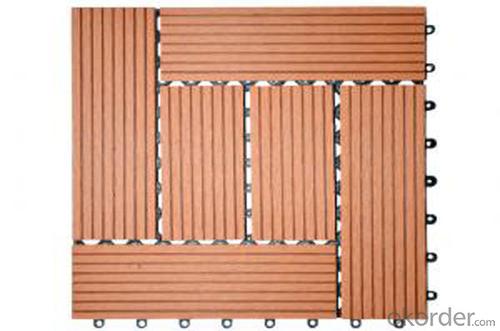

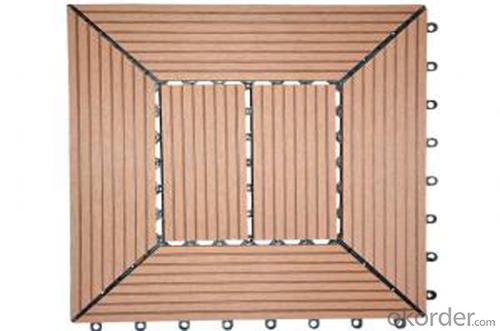

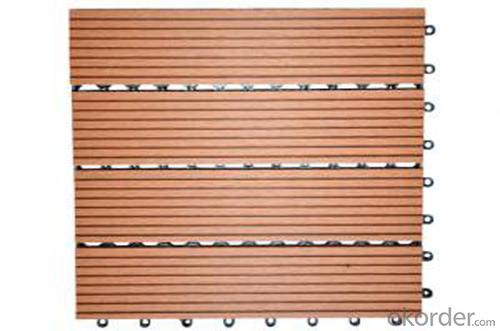

DIY WPC Interlocking Composite Decking Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of DIY WPC Interlocking Composite Decking Tiles:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

Composition of DIY WPC Interlocking Composite Decking Tiles:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of DIY WPC Interlocking Composite Decking Tiles:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

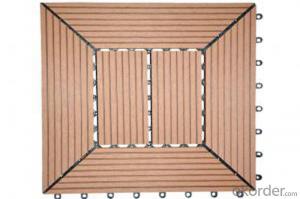

Installation of DIY WPC Interlocking Composite Decking Tiles:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of DIY WPC Interlocking Composite Decking Tiles:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: What's the function of the plastic film under the wood floor?

- Prevent moisture and moisture, so as not to the floor because of water seepage to the deformation of the wooden floor.

- Q: How to tear off the plastic film on the floor tiles

- Your turn is above if the plastic film may be the glass ceramics, finished directly to tear it, but to pay attention to, if it is microcrystalline stone, the surface of the glass is not scratch, when used to pay attention to, iron furniture must be wrapped, lest scratch, once scratch, there is no way to fix.

- Q: What is the difference between hard and soft plastic floor construction

- The difference is that in the construction of rigid plastic floor is easy to crack or break, and the soft deformation! Okay! Don't thank me

- Q: What is the role of plastic film on the ground floor? Can I have a white mat?

- Damp proof layer is required: geothermal paving requirements in the ground between the pad and the ground must be coated with a layer of moisture-proof film, the moisture-proof film can prevent the evaporation of the surface of the ground after the opening of geothermal heating moisture damage the floor. There are many manufacturers in order to save a little cost to reduce installation requirements, to the geothermal floor caused great installation risks.

- Q: What is the home improvement PVC plastic floor

- Printing film: imported printing layer and the printing layer produced by the domestic production of the color and fidelity is very good, and the general production of small printing layer is prone to fade. Consumers in the purchase of the best looking for a high degree of integrity of the business to buy, so as not to fade the color of the plastic floor, the impact of beauty. Wear resistant layer: due to the different manufacturers, the quality of the wear-resistant layer is also a big difference, the poor quality of the wear-resistant layer in addition to easy cracking is also easy to shrink, resulting in the edge of the floor. Also recommend consumers to find a high degree of integrity of the business to buy PVC floor.

- Q: Plastic floor glue how shop, suitable for use at home

- Floor leather referred to as civilian leather, poor quality of materials, can be used for a year, if the furniture and the like in the above pressure will be broken.Different uses! Different life! Different quality! Different price!

- Q: What is the price per square metre of plastic floor?

- And the price of this plastic floor in accordance with the use of different location, the difference between the laying of a slightly larger, then there will be some differences in prices. This is a common phenomenon.

- Q: What are the disadvantages of PVC plastic floor

- PVC plastic floor has many advantages, it also has shortcomings, but compared to other plastic floor, PVC plastic floor has been considered a good

- Q: Warm the house, with plastic floor?

- The varieties and patterns are very much, the price from tens of dollars to several hundred dollars, I give the child the choice is a 85 yuan, to the living room, bedroom and other choice is a 160 yuan, children room floor is the cartoon, colorful and beautiful, the other room is wood Road, in fact I think the shop is on the grade, and not before the kind of floor leather appearance, many people go to my home, feel very high-grade, style, and home decoration environment is very fit. And because the floor like wooden floor is a mosaic, but a whole, so there is no seams, children at home often pee or water ah, ah and milk on the floor, wipe with a rag on the line, do not have to worry about it will penetrate into the floor.

- Q: Is plastic floor glue toxic? Thank you

- Floor leather (toxic, mainly heavy metal exceed the standard): this kind of floor in black or dark bottom. Because of cheap, from 80s in China's mass production and application. Especially in the three northeastern provinces, a large number of people in the home are useful, with the promotion of commercial land in recent years, is now being reduced, and now the market is very environmentally friendly sales standards. Some are not under the environmental protection, but the surface is environmentally friendly, if there are children at home do not recommend the use of the more can not be used to artificial food mat

Send your message to us

DIY WPC Interlocking Composite Decking Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords