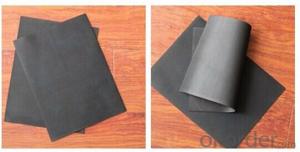

Wide EPDM pond liner or for landscape 2015 HOT

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

| EPDM waterproof membrane is made from ternary ethylene-propylene

rubber, which is for waterproofing of exposed and non-exposed applications.

| EPDM waterproof membrane production adopts the world-advanced equipment of

cold feeding extrusion and continuous vulcanization technology.

| EPDM waterproof membrane is of high elasticity among high polymer waterproof materials

and becomes a world-popular waterproofing material.

2. Specification

1) Material: EPDM Rubber

2) Size: 1.2m/2m/3m/4m (width)*20m (length) or customized,

3) Thick: 1.2mm, 1.5mm, 2.0mm

4) Type: Weldable

5) Pattern: Non-reinforced (homogeneous)

6) Certificate: ISO9001/14001

3. Features

| Excellent physical and mechanical performance

| High tearing resistance

| Good deformation adaptability

| High puncture resistance

| High aging resistance

4. Applications

l Roofs, Basement, Toilets

l Industrial and civil building waterproofing

l Geosynthetic liner for swimming pool, channels, irrigation system

l Especially suitable for projects with high requirements in durability, anti-corrosion and

deformation.

- Q: Can a waterproofing membrane be used for bridges or viaducts?

- Yes, a waterproofing membrane can be used for bridges or viaducts. Waterproofing membranes are commonly used in infrastructure projects to protect the structural elements of bridges and viaducts from water infiltration and damage. These membranes act as a barrier, preventing water from seeping into the concrete or steel components, which can cause deterioration and structural issues over time. By using a waterproofing membrane, the lifespan and durability of bridges and viaducts can be significantly increased.

- Q: Can a waterproofing membrane be applied to both interior and exterior surfaces?

- Yes, a waterproofing membrane can be applied to both interior and exterior surfaces.

- Q: Can a waterproofing membrane be used for a shower pan liner installation?

- Indeed, the utilization of a waterproofing membrane is possible for the installation of a shower pan liner. This specialized membrane is specifically crafted to establish a formidable defense against moisture and thwart any infiltration of water into the shower pan, thereby averting any potential harm to the underlying structure. The presence of a dependable and efficient waterproofing system is absolutely crucial in order to ensure the durability and soundness of the shower installation. By effectively sealing the shower pan and establishing an impermeable barrier, a waterproofing membrane can bestow this much-needed protection. It is imperative to select a membrane that is explicitly designed for deployment as a shower pan liner and to diligently adhere to the manufacturer's instructions for proper installation.

- Q: Roof SBS waterproofing membrane can not empty shop

- Whether the waterproofing membrane is empty is determined by two aspects. 1, the construction site requirements. Such as the basement of the bottom of the membrane waterproof specifications require empty shop; deformation of the steel roof can be a small amount of sticky open shop or shop shop to adapt to structural deformation, but the coil to have a certain pressure.

- Q: Is a waterproofing membrane resistant to punctures?

- Yes, a waterproofing membrane is generally designed to be resistant to punctures. It is engineered with durable materials and reinforced to provide protection against puncturing forces, ensuring its longevity and effectiveness in preventing water penetration.

- Q: Can a waterproofing membrane be used for a retaining wall drainage?

- Yes, a waterproofing membrane can be used for retaining wall drainage. The membrane helps to prevent water from seeping into the retaining wall and causing damage. Additionally, it can also help to channel water away from the wall, promoting proper drainage.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Indeed, stormwater management systems can benefit from the application of waterproofing membranes. These membranes are frequently utilized to safeguard structures against water infiltration and potential water-related harm. In the case of stormwater management systems, which are designed to collect, retain, and efficiently handle rainwater runoff, waterproofing membranes can be employed to establish a completely watertight seal, thereby averting leaks and seepage. Stormwater management systems often incorporate various components, such as retention ponds, infiltration basins, or underground storage systems. These elements must be adequately sealed to ensure the proper containment and effective management of the collected stormwater. When properly installed, waterproofing membranes serve as an impermeable barrier, effectively preventing water from escaping or infiltrating the system. The utilization of waterproofing membranes on stormwater management systems offers numerous advantages. Firstly, it helps to maintain the system's integrity and functionality by preventing leaks or seepage that could compromise its performance. This ensures that the stormwater is efficiently captured and managed, minimizing the risk of flooding or erosion. Furthermore, waterproofing membranes can significantly prolong the lifespan of stormwater management systems by safeguarding them against water damage. Water infiltration can lead to structural degradation, corrosion, or the proliferation of mold and mildew, all of which weaken the system over time. By establishing a waterproof barrier, these membranes contribute to the preservation of the structural integrity of the components, thus increasing their longevity and reducing maintenance requirements. Moreover, the use of waterproofing membranes on stormwater management systems also contributes to environmental sustainability. By effectively containing and managing stormwater runoff, these systems aid in reducing water pollution and enhancing the quality of natural water bodies. Waterproofing membranes play a vital role in preventing stormwater from carrying pollutants, such as chemicals or sediment, into rivers, lakes, or oceans. In conclusion, waterproofing membranes can be effectively utilized on stormwater management systems to establish a watertight seal, prevent leaks, and protect the components from water damage. By providing an impermeable barrier, these membranes help to maintain the system's functionality and integrity, prolong its lifespan, and contribute to environmental sustainability by reducing water pollution.

- Q: Is a waterproofing membrane resistant to UV radiation?

- Typically, a waterproofing membrane is resistant to UV radiation. Most manufacturers design these membranes to be durable and long-lasting, ensuring they can withstand exposure to UV rays. Over time, UV radiation from the sun can cause degradation and damage to various materials, including waterproofing membranes. To combat this, manufacturers often include UV stabilizers and additives in the membrane's composition. These additives prevent the breakdown of the membrane's structure, allowing it to remain effective in preventing water infiltration and maintaining its performance for an extended period, even when exposed to direct sunlight. Some waterproofing membranes may also have a protective layer or coating that offers extra UV resistance. To understand the specific UV resistance capabilities of a particular waterproofing membrane, it is advisable to consult the manufacturer's specifications and guidelines.

- Q: Are there any environmental considerations when using a waterproofing membrane?

- When using a waterproofing membrane, there are several environmental factors to consider. One major concern is the possibility of harmful chemicals or materials being used during production. Some membranes may contain toxic substances like volatile organic compounds (VOCs) or heavy metals, which can negatively impact both human health and the environment. Another consideration is how to properly dispose of the membrane at the end of its lifespan. Many waterproofing membranes are not biodegradable and can contribute to landfill waste. Incorrect disposal methods can lead to environmental pollution and harm ecosystems. Furthermore, the production of waterproofing membranes often involves energy-intensive processes and the extraction of non-renewable resources. This can result in greenhouse gas emissions and the depletion of natural resources. To address these environmental concerns, it is crucial to select waterproofing membranes that have been made using eco-friendly materials and processes. Look for products labeled as low VOC or free from hazardous substances. Additionally, consider using recyclable membranes or those made from recycled materials to decrease waste generation. Proper disposal of the membrane at the end of its life cycle is also vital, and options such as recycling or repurposing should be explored. In conclusion, it is essential to take the environmental impact of waterproofing membranes into account and choose products and practices that minimize harm to the environment and promote sustainability.

- Q: Can a waterproofing membrane be used in schools or educational buildings?

- Certainly, schools and educational buildings can certainly make use of waterproofing membranes. These membranes are specifically engineered to halt water infiltration and safeguard the structural integrity of the building against moisture-related harm. In educational settings, where numerous students and staff congregate, it becomes imperative to uphold a secure and hygienic environment. Waterproofing membranes can be effectively deployed in a variety of areas like basements, roofs, walls, and foundations to avert water seepage, dampness, and the proliferation of mold. By incorporating a waterproofing membrane into their infrastructure, schools can ensure the long-term sustainability of their buildings, safeguard valuable equipment and resources, and furnish a comfortable learning atmosphere for students and staff.

Send your message to us

Wide EPDM pond liner or for landscape 2015 HOT

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords