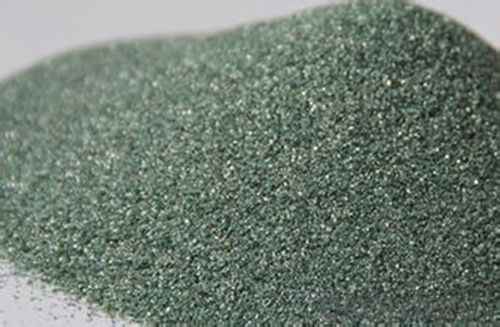

Raw Materials for Wear-Resistant Silicon Carbide Refractory Mortar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Jiangsu, China (Mainland) | Shape: | Powder | Material: | Castable |

| SiO2 Content (%): | / | Al2O3 Content (%): | 78% | MgO Content (%): | / |

| CaO Content (%): | / | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | / |

| SiC Content (%): | / | Model Number: | CA-10 | Brand Name: | CNBM |

| Name: | silicon carbide | Volume density: | 2.8-3.0 g/cm³ | Compressive strength: | 90 Mpa |

| Apparent porosity: | 20 % | Linear change on reheating: | 0.02% | Highest using temperature: | 1600 ℃ |

| Abrasion resistance: | 7 CC |

Packaging & Delivery

| Packaging Details: | container,ton-bag,and others could be discussed |

| Delivery Detail: | 3 Days upon order confirmed |

Product Description

wear-resistant silicon carbide refractory mortar

This refractory material can be made into abrasive refractory brick for circulating fluidized bed (CFB) and waste incineration. Our products enjoy excellent thermal shock resistivity and abrasion performance with small expansion coefficient.

Advantages:

1.Good wear resistance

2.High compressive strength

3.Good flexural strength

Specifications:

Business philosophy:

Since our establishment, we have persisted in the business tent of “Winning the customers with sincerity and creating the driving force with science and technology”. We always stick to scientific and technological innovation combined all forces with sincere enthusiasm, rigorous scientific attitude and pragmatic work style. Besides, we also take a sense of mission to give a new meaning of the traditional refractory and the furnace engineering , explain the meaning of environment protection and energy saving.

During the past years, our NO.1 priority has always been customer service and customer satisfaction. We pursue honesty, pay attention to creating the products with good quality. The society is progressing; times are changing, providing first-class products is our aim. As a result, we are famous for our superior quality, competitive prices, first-class craftworks and perfect services. Therefore we can fully satisfy your demands and have a large customer base.

- Q: Where is the production of refractory manganese alloy manufacturers? Manganese is recommended between 63 and 70!

- The cut is relatively transparent if you jam, we have also used silicon manganese alloy

- Q: Preparation of refractory clay

- Is it to make refractories? Add some andalusite to the refractory mortar will improve the effect.

- Q: What does fire-resistant insulation coating have?

- Refractory thermal insulation material mainly refers to the inorganic thermal insulation material and composite thermal insulation material. According to the shape, it can be divided into: Finishing of fibrous shape, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber, etc. Diatomaceous earth of microporous pile, calcium silicate, expanded perlite,expanded vermiculite,aerated concrete, etc. Foam glass of bubble shape, volcanic ash glass, foamed clay, foamed?concrete, gelatine powder polyphenyl granule heat insulating slurry of pasty form, etc. Their common feature is fire-retardant and firproof. It can be used in buildings with high requirements of fire?rating. Calcium silicate, aluminum silicate and asbestos can also be used for piping insulation of heat transport with high temperature. Hope it is helpful to you.

- Q: How is grade of fire endurance divided?

- Does anyone know about grade of fire resistance? How is grade of fire endurance divided?

- Q: What type of firebrick does TZ-3 represent?

- Height is 65mm, length is 230mm, and width is 114mm, that is the t-3 firebricks which meet the national standard.

- Q: What's the refractory material in common use currently?

- (1) Alumina-silica refractory brick: Except the transition band, hot end and firing zone of the rotatory cement kiln, it can be applied to the whole burning system of the precalcining kiln, such as the fixed wall lining, wicket, cooling machine, tertiary air duct, burner, etc. It mainly includes alkali-resisting brick, high alumina (anti stripping) brick, silica-mullite brick, etc. (2) Basic refractory: For the upper transition band close to the part of burning zone and the burning zone, its inner lining can endure the highest flame temperature of 2000℃ and material temperature of 1350℃-1400℃, and it also has to withstand the permeation of sulfur and alkali compounds, permeation, thermal shock and oxidoreduction of hot-melt clinkers (liquid phase), mechanical stress of elliptic cylinder deformation, etc. Therefore, inner linings are the most demanding parts to withstand stress, and only basic refractory can meet with requirements under this working condition. (3) Fireclay insulating refractory: Its microstructure has notable characteristics of high porosity, large pore size and thermal insulation performance. For its low volume density and light weight, it is usually referred to as lightweight refractory. Fireclay insulating refractory product has great varieties, and it is usually classified and named according to its chemical and mineral compositions or production raw materials, and it is also classified according to its operating temperature and material form. Currently, the most used main thermal insulation material for the precalciner kiln system at home and abroad is calcium silicate board; besides, light weight castable and insulating fire brick are increasingly used year by year. Other thermal insulation materials are mainly ceramic fiber products.

- Q: Can you tell me the classification of fireproof sealing material.

- Organic fireproof sealing material include: fire-proof sealing plate, foam sealing materials, flame retardant module, flexible organic plugging material, inorganic fire sealant, plugging and fire package, etc. Organic plugging material take organic materials as the adhesive with certain flexibility or plasticity when used. The product is thick liquid or cement. Inorganic plugging material take powder of solid inorganic material as the main ingredients, and admixture mixed use, with proper workability. Fireproof bag apply bag shaped object made up by fire-proof materia to large hole fire plug or cable tray fire compartmentation (fire package also called as refractory package or fire protection package). Fire modules is made up of fireproof material, which is a solid with a certain shape and size and can be easily cut and drilled, suitable for holes or fire-proof sealing of cable tray. fireproof sealing material is the plank made up of fireproof material, which is a solid with a certain shape and size and can be easily cut and drilled, suitable for holes or fire-proof sealing of cable tray. Foam block after injection holes can lathery foam and seal hole. Sealing strip is made of fire prevention materials with certain geometry shape or flexible coil geometry.

- Q: What level is the rock wool board fireproofing material ?

- The fire rating classification is a provision for all insulation materials, rather than to separately divide rock wool. Determine the value of the material fire rating according to the relevant test items of 8624. As the rock wool is made from basalt fusion, so it is the level A non-combustible material.

- Q: What are the commonly used fire protection materials

- Firewall. The fire wall is made of non combustible material, and is directly installed on the base of the building or the reinforced concrete frame or fire proof walls . Fireproof limit of the firewall, according to the current "building regulations", is 4 hours, wheras the specification of Technical specification for concrete structures of tall building is 3 hours. doors resistant to fire, heat in a certain period of time These door usually prevent the spread of fire and gas in the fire resistant wall, staircase, pipe well. Fire door can be divided into steel fire doors, wood fire doors and composite materials fire door according to the material used. According to the limit of fire resistance can be divided into the class A fire door (1.2h), B fire doors (0.9), class C fire door (0.6h); (3) fire window. Windows resistant to fire, heat in a certain period of time It is usually installed in the fire resistance wall or doors; the fire shutter. This roller shutter can be refractory in a certain period of time. It is typically used for heat and fire insulation in escalator with difficulties to install fire resistant wall, fire resistant valve and smoke resistant valve. Fire resistant valve is installed in the ventilation and air conditioning system of air supply and return air duct, usually in the open state, fire, It will be turn off when the pipeline gas temperature reached 70 degrees, can meet the requirement for fire resistance and insulation for gas and fire. Smoke fire resistant damper installed in the exhaust system pipe, when the pipeline gas temperature reached 280 degrees, it will close automatically, insulating fire and gas.

- Q: Is there a worker in (Jigang refractory plant)?

- Ha ha, base should be rest, you won't give you money, Hugh or those money, endlessly is your dedication. Should be double cease, ah, how do you say four days?. In theory, it's five days off now, and the three day of that is from the chairman to every employee.

Send your message to us

Raw Materials for Wear-Resistant Silicon Carbide Refractory Mortar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords