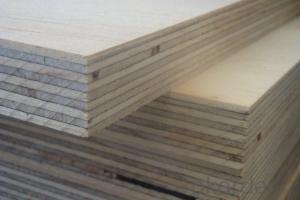

3/4 CDX Plywood - Brown Film Faced 21mm Melamine Glue Poplar Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Type:

Film Faced Plywood

Application:

For Construction

Specification:

Item:film faced plywood

Size:1220x2440mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,customer's thickness is available

Color:Brown,Black,Red

Description:

Product Name

Film faced plywood

F/B

Black film, brown film,red film

Grade

Construntion grade(one/two time hot press)

Core

Poplar, hardwood, birch, pine, combi , and so on

Glue

mealmine and WBP

Thickness

9-25mm

Specification

1220x2440mm, 1250x2500mm

Moisture Content

8-10%

Package

Standard export packing

Press

one times press/two time press grade

MOQ

1x20GP

Price Terms

FOB, CIF, CFR

Payment

T/T 30%, irrevocable LC

Delivery Time

Within 15 days after order confirmed

Supply Capacity

4000 cbc/month

Usages

Can be widely used for building concrete, etc

Remarks

Top class equipment with top class produce technique;

Credit first, fair trading

Formaldehyde Emission Standards

E2<30mg/100kg

E1<9mg/100kg

E0<5mg/100kg

Features:

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

Storage:

Always clean and repair the formwork panels before storage, the formwork should then be stacked off the ground on level supports and under cover. framed formwork panels should be stacked alternately face and back to back to avoid face damage by bolts etc. if panels are wet, do not allow them to dry too rapidly.

Sealing of Edges:

Phenolic film faced plywood edges are fully sealed by the factory and it is the most important that all edges remain sealed. to obtain full value from a phenolic film faced plywood sheet any recut edges should sealed as soon as possible with water proof paint sealing of holes.

any hole made in film faced formwork panels should also be sealed to prevent water entering. if water does enter it may cause swelling around the holes.

Cleaning and Repair:

To obtain full life, cleaning should be carried out immediately after each use. phenolic film faced plywood may be wiped with release agent or cleaned with water and stiffbrush. it may be necessary to use a hard wood scraper but care should be taken not to damage the plywood face. do no use a wire brush or sharp metal scraper to dislodge hardened concrete.

FAQ:

1.Can I be your agent?

Yes, welcome to deep cooperation. We have big promotion in the market now. For the details please contact with our overseas manager.2.Is OEM available?

Yes, OEM is available. We have professional designer to help your brand promotion.

3.Is the sample available?

Yes, samples are available for you to test the quality.

4.Are the products tested before shipping?

Yes, all was qualified before shipping. We test every batch every day.

5.What's your quality guarantee?

We have 100% quality guarantee to customers. We will be responsible for any quality problem.

6.What's benefit will you bring?

Your client satisfied on the quality.

Your client continued orders.

Your can get good reputation from your market and obtain more orders.

- Q: defects are divided into four grades

- Sanding plywood refers to the plywood of the sanding machine (or scraper) sanding (or scraper).

- Q: Now what is the market for plywood development?

- From January to December 2006, China's plywood manufacturing industry achieved a total industrial output value of RMB 75,819,437,000, an increase of 39.83% over the same period in 2005

- Q: Judging wood is the standard for plywood

- If you have an old piece of furniture, it is time to polish or throw it away, then you can make a decision by identifying the wood sometimes.

- Q: How do you choose plywood in plywood production?

- But should be described in the name of the product, such as "cedar veneer plywood", or "fir slices plywood", or "cherry wood trim".

- Q: How do I determine if plywood contains formaldehyde?

- Those who claim real real wood furniture, which often possession of plywood.

- Q: Further processing of the plywood

- Pre-finned plywood Prefinisked plywood The manufacturer has been treated with a special table without the need to modify the plywood.

- Q: Multilayer board and plywood difference

- The multilayer board is usually arranged symmetrically on both sides of the center or core.

- Q: The Preparation of plywood ingredients

- Loose loose side In the process of peeling or slicing, the side of the board and the knife contact side, this side due to reverse expansion and often produce a bottle peeling or cut fissure.

- Q: What is medium density fiberboard

- Its thickness specifications are 2.7,3,3.5,4,5,5.5,6,7,8 mm, commonly used specifications are 3,3.5,4 mm.

- Q: The basic principle of plywood

- The principle of symmetry is to require plywood symmetry on both sides of the plate, regardless of the nature of the wood, the thickness of the plywood, the layer, the fiber direction, the water content, etc

Send your message to us

3/4 CDX Plywood - Brown Film Faced 21mm Melamine Glue Poplar Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords