Geomembrana Quito Waterproof Polyethylene Film, Waterproof Geomembrane, Black HDPE Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

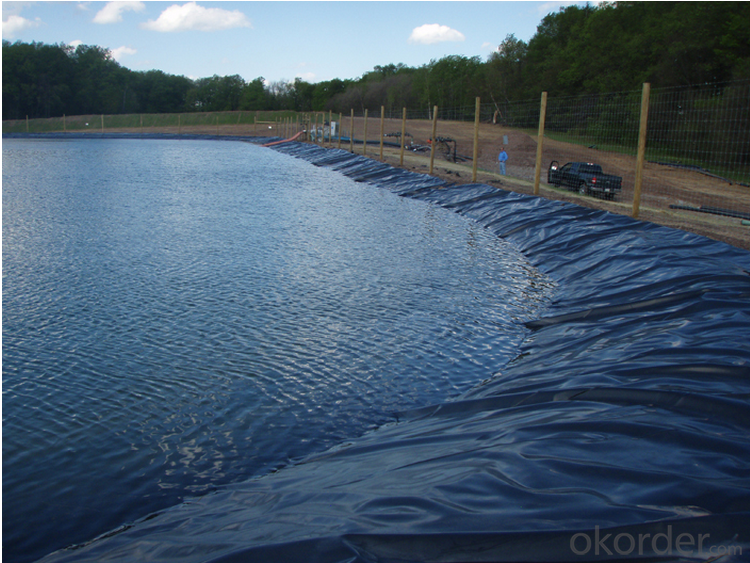

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

4. ASTM HDPE geomembrane technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Which one is better, geotextiles or composite geo-membranes?

- The main functions of geotextiles is reinforcement and filtration. Geotextiles have worse waterproofness than composite geomembranes. The composite geomembranes are combination of geomembranes and geotextiles. Composite geomembranes are waterproof mainly used for reinforcement. But they can't be used for filtration.

- Q: What are the considerations for geomembrane selection in landfill gas collection systems?

- When selecting a geomembrane for landfill gas collection systems, there are several key considerations to keep in mind. These include the material's resistance to gas permeability, chemical compatibility with landfill gases, durability and puncture resistance, flexibility for uneven surfaces, installation and maintenance requirements, and compliance with regulatory standards. Additionally, factors like cost, warranty, and the supplier's reputation should also be taken into account. Overall, choosing the right geomembrane involves evaluating various technical, practical, and financial aspects to ensure efficient and long-lasting gas collection in landfill systems.

- Q: How do geomembranes improve water efficiency in golf course irrigation?

- Geomembranes improve water efficiency in golf course irrigation by acting as a barrier to prevent water seepage and loss. They effectively contain and retain water within the irrigation system, ensuring that the water reaches the desired areas and is not wasted through leakage or evaporation. This helps golf courses optimize water usage, minimize water runoff, and reduce the overall water consumption, resulting in improved water efficiency.

- Q: What are the chemical resistance properties of geomembranes?

- Geomembranes generally exhibit excellent chemical resistance properties. They are designed to withstand exposure to a wide range of chemicals, including acids, bases, solvents, and hydrocarbons. These materials are often used in various industries, such as mining, agriculture, and waste management, where they come into contact with hazardous substances. The chemical resistance of geomembranes helps ensure their durability and effectiveness in protecting the environment and preventing contamination.

- Q: Are geomembranes suitable for use in hydraulic barrier applications?

- Yes, geomembranes are suitable for use in hydraulic barrier applications. Geomembranes are impermeable membranes made of synthetic materials that can effectively prevent the flow of fluids. In hydraulic barrier applications, they can be used to contain or control the flow of water, wastewater, or other liquids, ensuring environmental protection and preventing contamination. Their durability, flexibility, and resistance to chemicals and weather conditions make them an excellent choice for hydraulic barrier systems in various industries such as mining, agriculture, and construction.

- Q: Are geomembranes suitable for use in hazardous waste containment?

- Yes, geomembranes are suitable for use in hazardous waste containment. Geomembranes are impermeable barriers that prevent the migration of contaminants, making them effective in containing hazardous waste and protecting the environment. They have been extensively used in various hazardous waste management systems, such as landfills, to provide a reliable and long-lasting solution for containment and preventing the release of harmful substances into the surrounding soil and groundwater.

- Q: How do geomembranes contribute to the preservation of endangered species?

- Geomembranes can contribute to the preservation of endangered species by creating protective barriers that prevent contamination of their habitats. These impermeable liners are often used in landfills or waste containment facilities to prevent leakage of harmful substances into the environment, helping to maintain the quality of water sources, soil, and air. By ensuring the integrity of ecosystems, geomembranes indirectly support the survival and well-being of endangered species by safeguarding their habitats from pollution and degradation.

- Q: What are the considerations for geomembrane selection in wastewater treatment plants?

- Some considerations for geomembrane selection in wastewater treatment plants include the material's chemical resistance, durability, flexibility, and compatibility with other components of the treatment system. It is important to choose a geomembrane that can withstand exposure to various chemicals and contaminants commonly found in wastewater. Additionally, the chosen geomembrane should have a long lifespan and be able to withstand physical stresses such as UV exposure, temperature fluctuations, and mechanical damage. Flexibility is also important to ensure the geomembrane can conform to the shape of the treatment system. Lastly, compatibility with other components such as pipes, valves, and fittings should be considered to ensure proper installation and functionality of the system.

- Q: How do geomembranes contribute to landfill capping?

- Geomembranes play a crucial role in landfill capping by acting as a barrier to prevent the release of harmful substances into the environment. They are placed on top of the landfill, effectively sealing it off and preventing the contaminants from leaching into the soil and groundwater. This helps to protect the surrounding ecosystems and human health while also preventing the spread of odors and gases from the landfill. Additionally, geomembranes can provide stability to the landfill cap, preventing erosion and ensuring the long-term integrity of the waste containment system.

Send your message to us

Geomembrana Quito Waterproof Polyethylene Film, Waterproof Geomembrane, Black HDPE Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords