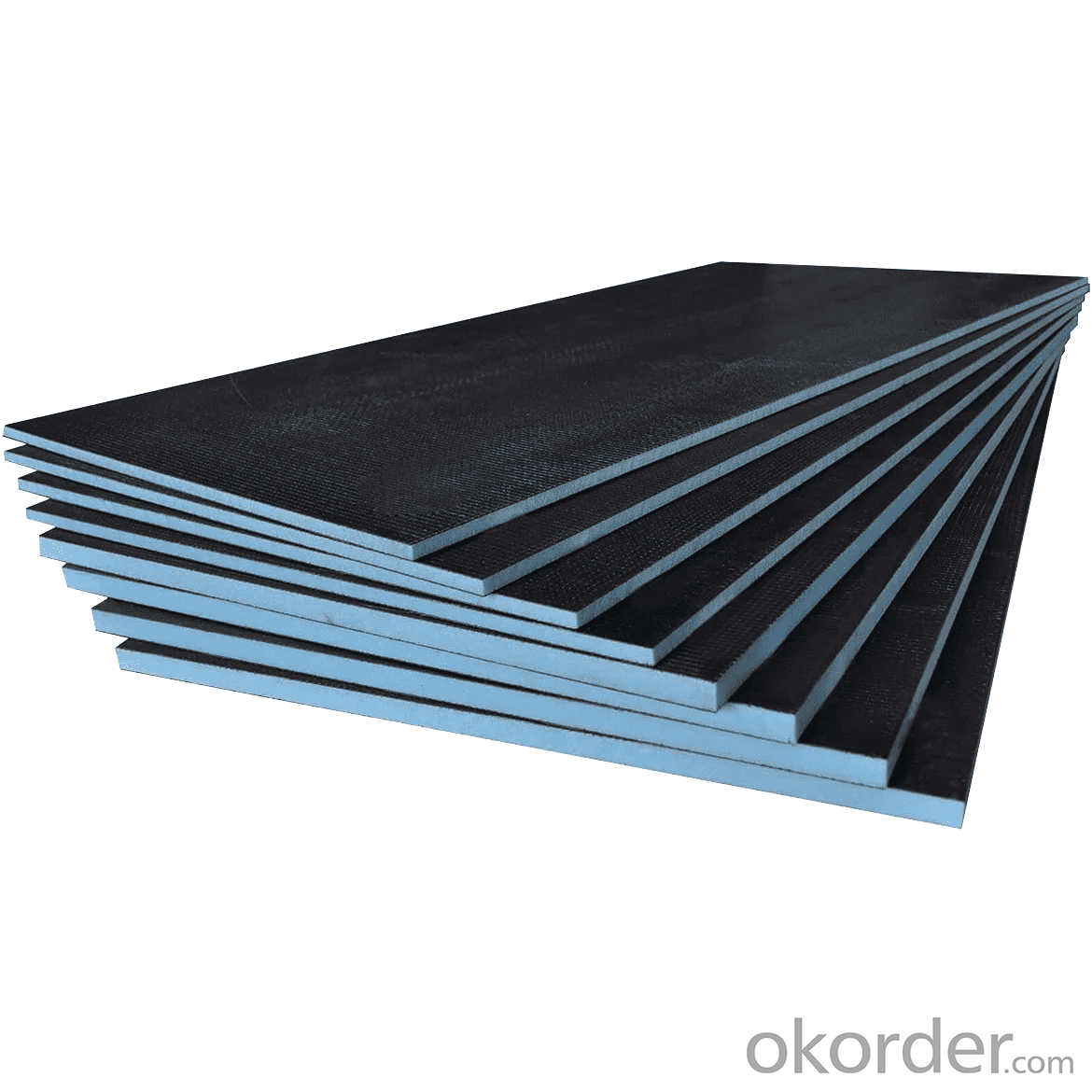

Waterproof Insulated Backer Board For Tile Shower Walls

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

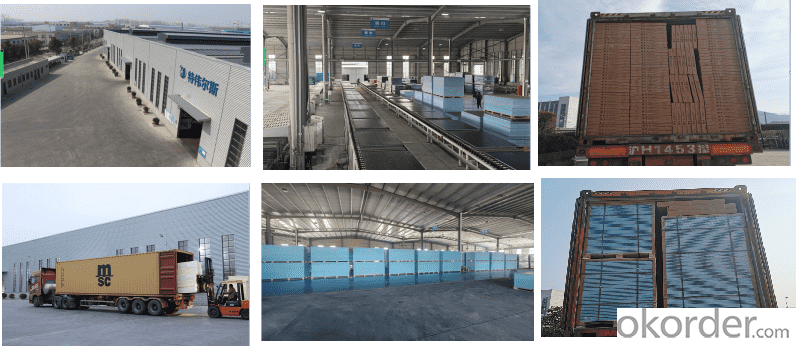

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wetroom 12mm xps Tile Backer Board For Walls and Floors 1200mm x 600mm (10 Pack)

When it comes to effective insulation solutions for your construction or tiling projects, XPS insulation boards are a reliable choice. we offer a wide range of XPS insulation boards, also known as XPS foam boards or simply XPS boards. These boards are designed to provide excellent thermal insulation, moisture resistance, and durability, making them ideal for various applications.

XPS insulation boards are constructed from extruded polystyrene foam, known for its high compressive strength and low thermal conductivity. This combination of properties makes XPS boards highly efficient in reducing heat transfer and improving energy efficiency in buildings. Whether you're insulating walls, floors, or roofs, XPS insulation boards offer a reliable solution.

Our selection of XPS foam boards includes various thicknesses and sizes to accommodate different project requirements. From smaller DIY projects to large-scale commercial installations, we have the right XPS insulation board to suit your needs. These boards are easy to handle and cut, allowing for precise fitting and installation.

we pride ourselves on providing high-quality products and exceptional customer service. Our knowledgeable staff are available to assist you in selecting the right XPS insulation board for your specific project. We also offer fast shipping and hassle-free returns to ensure your complete satisfaction with your purchase.

Whether you're a professional contractor or a DIY enthusiast, our XPS boards will help you create a comfortable and energy-efficient environment.

Performance parameters

Technical | Assessed to | Rating |

XPS Foam Density | DIN 53420 | 32±0.02kg/m³ |

Compressive strenghth (kPa) | EN 826 | ≥450 |

Thermal conductivity(W/m・K) | EN 12167 | ≤0.030 ≤0.034 |

Dimesional stability % (70±2℃) 48h | GB/T8811-2008 | ≤1.5 |

Flexural Strength (Mpa) | ASTM C203 | ≥2.8 |

Water Absorption(96hrs immersion) | ISO 2896 | ≤1.5 |

Water Vapour Permeability | ASTM E-96 | ≤3.0 |

Flammability | EN13501 | B2 |

Tensile strength perpendicular to the board | GB/T30595-2024 | ≥0.2Mpa |

Advantages

Advantages

1. impact resistant and rigid.

2. Waterproof and temperature resistant & Vapour retardant.

3. Thermally insulating.

4. Quick and easy to install.

5. Lightweight, easy to handle and transport.

6. Easy to cut (with a utility knife).

7. Applied to use on any kind of background substrate.

8. Applied to freestanding p

artition walls,shelves, coverings and similar surfaces.

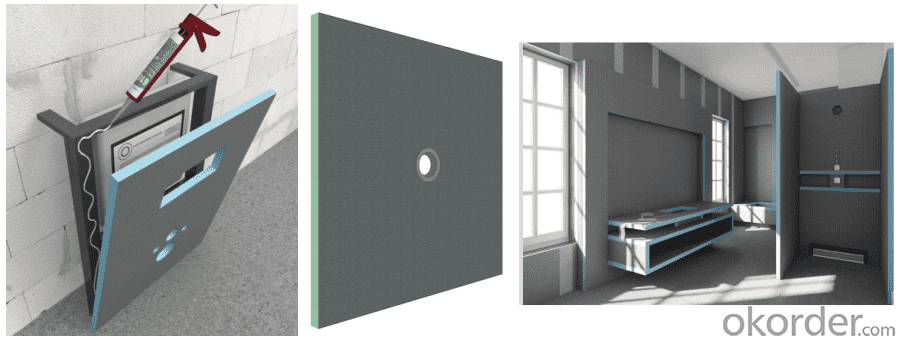

Applications

Bathrooms and Showers: Perfect for walls and floors in showers and bathrooms where water exposure is constant.

Kitchens: Ideal for kitchen backsplashes and countertops, providing a moisture-resistant base.

Wet Rooms: Suitable for creating fully waterproof wet rooms with tiled surfaces.

Exterior Spaces: Can be used in outdoor areas where moisture and temperature changes are a concern.

- Q: What is PE waterproof cloth and PVC tarpaulin

- PVC (tarpaulin) Features: coated high-strength polyester waterproof cloth is a high-strength polyester canvas-based cloth, coated with polyvinyl chloride (PVC) paste resin with accelerator, anti-mildew agent, anti-aging agent, anti Electrostatic agents and other chemical additives, made by high temperature plastic. Waterproof, anti-aging, anti-static and other properties; and the product breaking strength, tear elongation, tear strength is much better than the traditional tarpaulin; product appearance colorful, it is pleasing to the eye. The surface of the special treatment from the anti-skid effect, is the international popular waterproof cloth, and the width of large, reaching 2 meters wide, processing products can reduce the patchwork to improve the quality, can be used to heat sealing stitching, The And according to user needs to produce different functions, different colors, different thickness of the product.

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 2, when the basement depth is large, it is impossible to dig a place in time, you can use the reverse construction method, that is, dig a certain depth, then finished a section of retaining wall, to be a certain strength, and then open Dig, do the next retaining wall, and in this order until the construction to the specified design depth.

- Q: Find the construction steps for waterproof coatings

- 2, waterproof layer construction sequence and methods (1) base surface treatment and acceptance of qualified, and now Yin, Yang angle and construction joints and other special parts brushing waterproof coating layer, strengthen the layer 1 mm, strengthen the layer after brushing, immediately paste fiberglass cloth or 30 ~ 40g / ㎡ polyester cloth reinforcement layer, is strictly prohibited to strengthen the surface layer and then paste the reinforcement layer material. (2) to strengthen the layer of hard work, began to brush a large waterproof layer, waterproof layer using multi-channel (3 to 5) brushing, brushing the upper and lower coating should be perpendicular to each other. When the surface of the coating is completely cured (not sticky hands) before the next curtain coating construction. (3) polyurethane coating waterproofing layer after the completion of the experience of acceptance, the timely application of the waterproof layer of the protective layer, the plane protective layer with 7 cm thick fine stone ㎝, in the pouring of fine stone before the need to cover the waterproof layer A layer of 350 # paper tire linoleum insulation layer. Facade waterproof layer (such as anti-beam facade) with a thick 6 mm polyethylene foam protection (expansion ratio of not more than 25 times).

- Q: How does the finished ventilator manufacturer waterproof?

- Rooftop natural ventilator waterproofing measures are mainly two kinds, one is the traditional silicone, adhesive tape waterproof, the other is the structure of water, the national standard Atlas 11CJ33 "ventilation and light skylight" recommended the use of structural waterproof technology.

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- SBS Styrene-based thermoplastic elastomer is the largest yield (more than 70%) of SBCs, the lowest cost and wider application. It is a triblock copolymer with styrene and butadiene as monomer. Plastic and rubber properties, known as the "third generation of synthetic rubber".

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- 2, the mold of the nail set: in accordance with the pre-scheduled area along the painted bottom line nail with polyethylene film wrapped wood mold. Mold to be flat, with the basic nail implementation, to prevent leakage material.

- Q: What are the key points and contents of the quality control of waterproof material?

- 1, polymer cement waterproof coating: it consists of a variety of water-based polymer emulsion and a variety of additives mixed with high-quality cement powder composition. Because of its high cost of polymer emulsion components (about 19,000 yuan / T), and the low cost of powder (about 800 yuan / T), it is because the liquid material, powder huge spread, the vast majority of fraud is to use 801 Glue + fossil powder + green dyestuff + cement blending; the other is to change the liquid material, the proportion of powder will be your liquid material consumption, as much as possible to increase the amount of powder. Resulting in poor waterproof coating adhesion, intolerance, after the completion of the finished product should not be too hard to pull down by hand, and was not much ductility of the sheet or even hand rub a few times into a powder, with blisters Will break down into small pieces. Can also be used to cut the finished product coating and then placed in the refrigerator freezer room after 8 hours to remove, gently forced to break will be broken, and the national standard requirements of the material to achieve low temperature flexibility -10 ℃.

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- First, rigid (concrete) waterproof roofing SBS membrane should not be painted before the coating of any waterproof coating, otherwise it will damage the bonding strength of the coil and the grassroots.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material is divided into four categories, namely, PVC material, aluminum gusset material, waterproof gypsum board, sauna board. Kitchen bathroom ceiling material 1: PVC material ????PVC is made of vinyl chloride in the role of the initiator made of thermoplastic resin, made of honeycomb shape. Suitable for use in damp places such as kitchen and toilet, because the PVC material ceiling in the life of a certain guarantee, you can use for 50 years without damage, while waterproof, heat insulation effect is good, but also has a certain noise Effect, in the kitchen is the best use of the ceiling material.

- Q: Waterproof material water leakage construction should pay attention to what

- 3, do the closed water test After the waterproof construction is completed, the water storage test. Will be blocked all the toilet outlet, the door at a pound of about 200mm high barrier, and then poured in the bathroom about 20mm ~ 30mm deep water, and 24 hours after the inspection of the walls and the ground around the leakage phenomenon , Waterproof test is to ensure the quality of the bathroom waterproofing the key, we must do. Such as after 24 hours without leakage as qualified. If you find a leak, you should immediately stop the water storage test, re-waterproof layer to improve the treatment, after passing the water test.

Send your message to us

Waterproof Insulated Backer Board For Tile Shower Walls

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products