Wafer Check Valve_Duo Check Valve-PN10/PN16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | bubble bag+ paper case+ wooden box, OR per custoers' requiremen |

| Delivery Detail: | 7days, 15days, 30 days, according to customers' requirement |

Specifications

1.wafer check valve

2. approved by CE and ISO9001

3. meet ANSI,DIN,BS,etc

4. manufacturer supply

5. OEM valve accept

wafer type ,Duo check valve

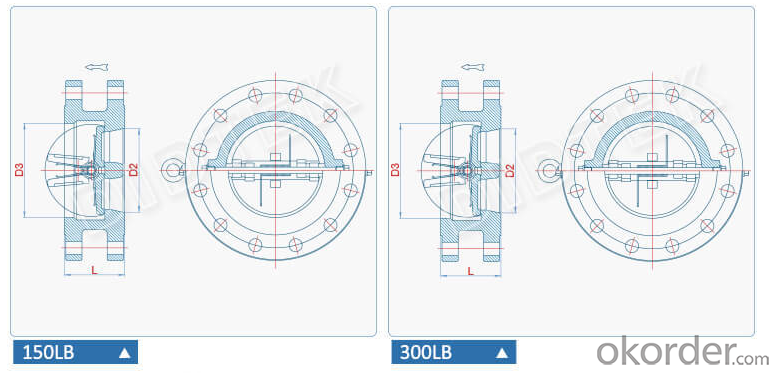

The standard of wafer type, duo check valve

1. Design standard conform to: MSS SP-67, API609, EN593

2. Connection flange conform to: DIN PN10/16/25, ANSI B16.1, BS4504, ISO PN10/16,

JIS B2212/2213, BS 10 Table D, BS 10 Table E

3.Top flange conform to: ISO 5211

4.Face to face conform to: API609, ISO5752 series 20, BS5155

5.Test standard conform to: API598

The design characters of wafer type duo check valve

Check valve is used for preventing the back flow of medium in pipelines and equipments. It will open and close automatically by the pressure of medium. When the medium is back-going, valve disc will close automatically to avoid accidents.

1. Tightly sealed, without leakage under the water pressure testing.

2. Economical, light weight, compact design-significantly lighter and less expensive than comparable swing check valves.

3. Easy to install and maintain.

The perfomance of wafer type, Duo check valve

1. Nominal Diameter: DN40-DN1200

2. Nominal Pressure PN (MPa): 1.0, 1.6, 2.0, 2.5

3. Testing pressure (water) Ps (MPa)

4. Body seat: 1.5 times rated pressure

5. Seat test: 1.1 times rated pressure

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Check valve 1 inches DN25 what do you mean?

- Crown valve pressFirst, an inch equals DN25That is, fixed values to estimate how large a pipeline isOne inch of check valve is mostly copper check valveThe price of I should be around 25 yuan

- Q: Why can't parallel check valve be installed firmly?Anonymous browsing | 51 times

- The vertical installation is easy to cause the valve core of the check valve to clamp off or fall off, and lose the function of checking back. The direction of the check valve is restricted seriously from any direction of the medium

- Q: Is the hdf41x 1.6Mpa a check valve?

- Backflow prevention device according to tap water supply equipment, especially drinking water pipe back to serious pollution, and effectively prevent the pollution device under the condition of a strictly limited hydraulic control assembly pipeline water only one-way flow of development, its function is to prevent backflow pipeline media in any condition, in order to avoid the purpose of backflow pollution.

- Q: Where can I find the good check valve?

- If the soft seal check valve, or buy Tianjin Hengyuan valve, good quality, moderate price, have the shelf life.

- Q: What can I do with the lift check valve?

- With the structure of short length, small volume and light weight, the valve closed fast, water hammer pressure, flow smooth, fluid resistance small, horizontal or vertical pipe pipe can be used, easy installation, quick action, good sealing performance, the valve stroke is short, close the valve impact force is small, simple and compact, beautiful appearance, service life long, high reliability, to prevent the media back, the characteristics of automatic control. A lift check valve is used on an industrial pipe to prevent the flow of a medium.

- Q: The check valve on the air pipe is installed in front of the fan and is there any difference in the back (direction is correct)?

- The principle is feasible, but the opening is definitely lagging behind, it will lead to poor ventilation, it is not recommended.AskOh, well, I see. I'll put him in the front. But in this case due to installation problems, only to fan up.

- Q: What are the differences between the vertical check valve and the horizontal check valve in function and principle?.

- First of all, the outward appearance of the vertical check valve flow direction, that is, the direction of check valve installation is vertical to the horizontal direction. The horizontal check valve is horizontal.

- Q: Tap water tank with vertical and horizontal check valve.

- Ball valves usually have very narrow seats, and may remove solids and make seating more efficient.The problem of vibration may be limited to small valves. When the valve is large, the inertia of the moving parts increases. The increased inertia may effectively damp the vibration and cause delayed closing, after the backflow has started. The damping of the seat becomes very important.All valves must check the flow path area and calculate the flow velocity for the design operating conditions. The area of the disc and piston is as important as the area of the main orifice. The smaller runner areas are corrosion prone and may cause cavitation wear.For specific functions, the valve body of the check may include auxiliary connections such as vents and drains. Hot applied valves may sometimes have a bypass valve to allow the system to warm up at low flow.

- Q: Is the check valve a check valve? What is its main purpose?

- Check valve, also known as one-way valve or check valve, its role is to prevent the medium back in the pipeline.

- Q: How to install the kitchen flue check valve?

- 1, vertical transport, the flue should take protective measures, and must be two lifting.2. Locate the center line of the flue position. In the reserved hole, draw down four vertical central lines from the roof, and draw 2 orthogonal central lines on the floor plane.3, the flue to the scene, the first flue hanging to the roof, surrounded by the center line of pop in the flue, and the flue of the reserved hole slowly down the electric hoist, from top to bottom layer installed flue in place, the center line correction. The center line of the flue and the center line of the reserved hole should be less than 1cm, the deviation of the centerline of the upper and lower flue is not greater than 1cm, and each flue must be guaranteed vertically and vertically.4, the installation of flue should each layer as bearing, bearing steel 2 root diameter over 14mm?.5. After the flue is installed, install the check valve hole at each flueFire type flue check valveFirst, stir the cement with a special glue, coat the edges of the check valve, and then install it at the opening of the check valve.6, the construction should be reserved at all levels of the hole, covered with a cover plate, to ensure safety in construction, to prevent construction waste fall into the flue.7, the flue is thin-walled components, in handling and installation should be gently handle, not to impact, not in the pipeline to pile other heavy objects and walking.8, the roof flue should be in the roof insulation layer, fire layer before construction. 9, the use of gas water heater exhaust system is strictly prohibited.

Send your message to us

Wafer Check Valve_Duo Check Valve-PN10/PN16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords