Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve

Design Feature Of Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve:

The products feature a reasonable structure, reliable seal, good performance and nice modeling.

Either soft or hard seal can be selected for the product upon different working conditions. The sealing face is built up with Co-based carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

Small opening pressure, the disc can be opened fully with a very small pressure differential.

Inside-set bolt-bearing structure reduces leakage and reliable use.

Class≥1500LB, the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along with the pressure rise so as to ensure the sealing performance.

Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirement.

Specifications Of Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve:

Class 150~1500, NPS 1/2~36"

Basic Design: ANSI B16.34, BS 1868

Face to Face Dimension: ANSI B16.10

Flanged Ends: 2~24" to ANSI B 16.5, >24" to MSS SP-44, to API 605 on request

B. W. Ends to ANSI B 16.25

Manufacturing to NACE MR-01-75 on request

Dimensions:

Size(DN) | L | D | D1 | D2 | b | n-d | H | W.T(kg) |

40 | 180 | 150 | 110 | 84 | 18 | 4-19 | 110 | 9 |

50 | 200 | 165 | 125 | 99 | 20 | 4-19 | 130 | 13.4 |

65 | 240 | 185 | 145 | 118 | 20 | 4-19 | 140 | 17.7 |

80 | 260 | 200 | 160 | 132 | 22 | 8-19 | 150 | 20.8 |

100 | 300 | 220 | 180 | 156 | 24 | 8-19 | 160 | 29.3 |

125 | 350 | 250 | 210 | 184 | 26 | 8-19 | 190 | 47 |

150 | 400 | 285 | 240 | 211 | 26 | 8-23 | 210 | 67 |

200 | 500 | 340 | 295 | 266 | 30 | 12-23 | 250 | 118.7 |

250 | 600 | 405 | 355 | 319 | 32 | 12-28 | 310 | 171.9 |

300 | 700 | 460 | 410 | 370 | 32 | 12-28 | 340 | 232.5 |

350 | 800 | 520 | 470 | 429 | 36 | 16-28 | 450 | 330 |

400 | 900 | 580 | 525 | 480 | 38 | 16-31 | 520 | 460 |

450 | 100 | 640 | 585 | 548 | 40 | 20-31 | 550 | 580 |

500 | 1100 | 715 | 650 | 609 | 42 | 20-34 | 590 | 700 |

600 | 1300 | 840 | 770 | 720 | 48 | 20-37 | 680 | 780 |

Trim Material to API 600

Seating | Seat Ring | Disc Seat | Hinge Pin Part NO. 13 |

1 | 13Cr | 13Cr | F6 |

2 | 304 | 304 | F304 |

5 | Stellite | Stellite | F6 |

8 | Stellite | 13Cr | F6 |

9 | Monel | Monel | Monel |

10 | 316 | 316 | F316 |

13 | Alloy20 | Alloy20 | Alloy20 |

Test Pressure to API 598

Class | Body Material | Shell Test (Hydrostatic) | Seat Test (Hydrostatic) | Seat Test (Air) |

150 | WCB | 450psi | 315psi | 80psi |

WC6 | 450psi | 319psi | ||

CF8M | 425psi | 303psi | ||

300 | WCB | 1125psi | 814psi | |

WC6 | 1125psi | 825psi | ||

CF8M | 1100psi | 792psi | ||

600 | WCB | 2225psi | 1628psi | |

WC6 | 2250psi | 1650psi | ||

CF8M | 2175psi | 1548psi | ||

900 | WCB | 3350psi | 2442psi | |

WC6 | 3375psi | 2475psi | ||

CF8M | 3250psi | 2376psi | ||

1500 | WCB | 5575psi | 4078psi | |

WC6 | 5625psi | 4125psi | ||

CF8M | 5400psi | 3960psi |

Usage/Applications Of Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve:

Check Valves are used in pipes under pressure between Class 150~2500LB, working temperatures﹣196~600℃. They are used in industries including oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

Tests Of Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve:

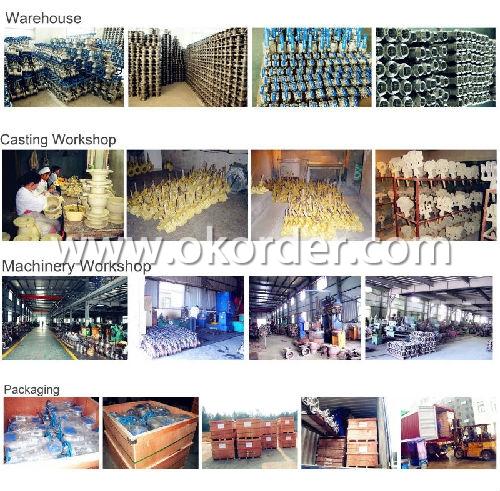

Packaging & Delivery Of Forged Steel Piston ANSI Swing Flanged Check Valve: Packaging: Inner packing: Plastic bags, Outer packing: Cartons and wooden case. Delivery: By Sea in 20ft and 40ft containers We can supply high quality of Forged Steel Piston ANSI Swing Flanged Check Valve with best price and fast delivery.

- Q: The working principle and structure description of the mute check valve

- 1, when the medium according to the provisions of the direction of flow, the valve by the media force, is open; the medium back, due to weight and disc valve by the medium reverse force, so that the sealing surface of the valve flap and valve seat sealing and closed, to prevent the media counter to.2, the body and valve sealing surface using stainless steel surfacing.3, the length of the valve according to the provisions of GB12221-1989, flange connection size according to the provisions of JB/T79-1994.

- Q: How much pressure is the check valve h47x-10q?

- Check valve h47x-10q is 1.0MPa pressureAccording to the provisions of the JB/T 308-2004 valve type programming method:H== check valve4== connection: flange7== structure: butterfly typeX== sealing surface material: Rubber10== pressure rating: 1.0MPaQ== body material: ductile iron

- Q: Is it necessary to install a check valve for suction well pumping well? If you need to install what kind of check valve (about lifting, butterfly valve, also a what to forget), which (installed in the water outlet, water inlet, or water pipe), ask again need to install the filter valve? I do not understand, ask for expert doubts! Thank you very much!

- The filter screen is arranged at the water inlet check valve and is installed below the water pump

- Q: Check valve does not automatically check back, how to adjust?

- The non-return valve does not automatically check the cause:1, the valve at both ends of the road must be blocked, there is dry ventilated room. Such as long-term storage, should always check rust corrosion.2, the valve should be cleaned before installation and eliminate the defects during transportation.3, the installation must be carefully checked on the valve signs and nameplates are in line with the use of requirements.

- Q: What type of check valve should be installed before the suction pump?

- Self priming pumps are equipped with rotary, rotary or automatic type check valves.Check valve, also known as one-way valve or check valve, its role is to prevent the medium back in the pipeline. Pump water off the bottom valve check valve also belongs to class. Forged steel check valves two body cover to connect the design form: the first is the body cover bolt connection forged steel valve, connected by this form of valve, the valve body and the valve cover bolt connection, spiral wound gasket seal, the advantage of easy maintenance;

- Q: Do you still need to check valve fittings for solar water heater installation?

- Now do not install check valve, install the hand to valve, at the bottom

- Q: How to install fire fighting pipe and flue fire check valve?

- 1, vertical transport, the flue should take protective measures, and must be two lifting.2. Locate the center line of the flue position. In the reserved hole, draw down four vertical central lines from the roof, and draw 2 orthogonal central lines on the floor plane.3, the flue to the scene, the first flue hanging to the roof, surrounded by the center line of pop in the flue, and the flue of the reserved hole slowly down the electric hoist, from top to bottom layer installed flue in place, the center line correction. The center line of the flue and the center line of the reserved hole should be less than 1cm, the deviation of the centerline of the upper and lower flue is not greater than 1cm, and each flue must be guaranteed vertically and vertically.

- Q: What's the difference between the check valve and the stop valve?

- The check valve is not the same as the cut-off valve. The difference between them is mainly that the structure is very different.Check valve is a one-way valve, automatically prevent reverse flow of fluid, no knob, can not be artificial blocking forward flow.The valve has a knob, and the controller can control the forward flow. Because of its special structure, the fluid can not flow backwards even if there is no artificial valve.

- Q: What is the difference between the check valve h64h-250 and the h61y-250?

- According to JB/T308-2004 "valve type programming method"One is the swing check valve (4), and the sealing surface is Cr13 (H)One is the lift check valve (1), and the sealing surface is made of Y

- Q: How does the check valve work?

- Only one-way flow, blocking the valve seal, liquid can not be returned.

1. Manufacturer Overview

| Location | Beijing,China |

| Year Established | 1986 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Asia, America, Europe, Middle East, West Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Beijing |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 498 People |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | 42000 square meters |

| No. of Production Lines | Above 20 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords