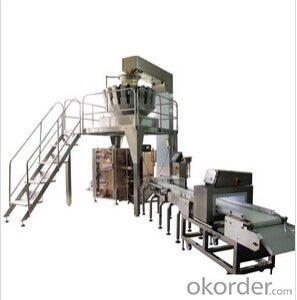

VG42 High Speed Packaging Machine ( MD18 heads combination weigher)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a professional manufacturer of food packaging machines. We are major in the packing machine for more than 11 years.

In China, we are the leading company in this area. Our machine exported over 40 countries and welcomed by the customers since good quality but inexpensive. The best quality of the machine will make user increase productivity and reduce maintenance costs, achieve higer economic efficiency. We got CE & ISO9001:2000 certification. Also, we have perfect after-sale service, when the packing machine has problems just send us an E-mail, our engineer will reply you how to solve the problem or go to your factory. We have the comprehensive abilities in many fields such as design and development of whole projects, production and manufacture, installation and testing, technical training and surpport. Adhering to the spirit of "quality, efficiency, credibility and practicality", we guarantee the high quality of our products.

With the market spreading over Europe, America and Southeast Asia, we sincerely hope to cooperate with customers from all over the world. Please contact us for more details. We ensure to provide qualified products with the best service.

VG42 high speed packaging machine

* Three Specifications

The machine is controlled by three servor motors, with continuou pulling film system and of maximum speed can catch 120 bags/min

Item | Content |

Capacity | 100-120 bags/min |

Bag size | (L)50-300mm (W)50-200mm |

Max film width | 420mm |

Film thickness | 0.04-0.09mm |

Pulling belt type | Intermittent pulling film |

Air consumption | 0.8Mpa 0.3m3/min |

Main power/voltage | 4KW/220V 50/60Hz |

Dimension | L1850*W1100*H1450mm |

Weight | 700kg |

Features

servo motors for film drawing down system. Automatic film rectifying deviation function.

* Horizontal sealing controlled by servo motor;

* Famous brand PLC. Pneumatic system for vertical seal and horizontal seal;

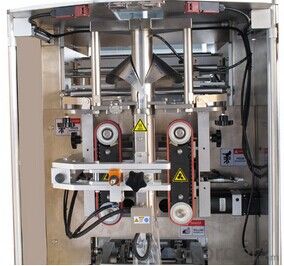

MD18 heads combination weigher

Features

*Adopt high precision digital weighing load cell and A/D module to get preciser weighing than before.

*LCD operating display with multiple languages such as English, Russian, German, Spanish,Italian, etc.

Specification

Item | Parameter |

Drive method | Stepper motor |

The max weighing | 3000g |

Type of weight setting | 99types |

Accuracy | ±0.1~1.5g |

Max capacity | *80bags/min |

Hopper Capacity | 150-2000ml |

Type of hopper | Double layer without memory |

Dimension | L1150xW950xH1129mm |

Voltage | 2KW 50/60/HZ 220V |

TK9 Z type Bucket Elevator (including the vibration feeder)

Features

The conveyor is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. It’s used for vertical feeding of grain or small block material.

Supporting Platform

Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher. In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

Specification

The size of the supporting platform is according to the type of the machines.

TP200 Finished Products Conveyor

Features

Automatically transport the finished products to the turn table which can rotation 360° convenient packaging.

- Q: What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- Hello, in recent years, Chinese packaging industry, although the annual growth rate ranked in the traditional industry for the first time, but in line with the international market, to accelerate the development of packaging technology, make its development to the economic, efficient, multi-functional direction. According to the development plan of Chinese national economy and to realize well-off life level, this year a few years for the packaging industry, the food industry to provide equipment for 100 billion yuan to 200 billion yuan, 80 billion yuan to 100 billion yuan to provide equipment for the "vegetable basket", this is a good opportunity for development of enterprises. At the same time, I learned from the relevant ministries, "95" period, will invest 10 billion yuan in the packaging industry to support and transform large and medium-sized packaging enterprises.

- Q: What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: What's the best place to use the pillow type packing machine?

- In the early communication can be reflected, and sometimes non-standard customized to see the level of Technology

- Q: Whether you can press paper plastic molding after PET

- Another hot pressing mould pressing needs, blister sealing machine uses a plastic bakelite mold mold, high frequency plastic welding machine is used Aluminum Alloy mold. The size of the mold needs to be determined by blister.

- Q: What is the working principle of the pillow packing machine?

- In fact, the special machine is often better than the packaging of the compatible machine. A packing machine should be packed in no more than 3-5 varieties. What's more, the products with the larger size and the difference in size should be packed separately as much as possible.

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q: Energy saving reform of packaging machine

- Due to the adoption of variable frequency speed regulation, the chain drive is greatly reduced, the stability and reliability of the operation of the machine are improved, and the noise of the machine operation is reduced. It guarantees the high efficiency, low loss and automatic detection of the packaging machine. It has both a beautiful and fashionable appearance, and a healthy and smart mind.Although the transmission system used in food packaging machine is relatively simple, it has higher requirements for the dynamic performance of the transmission. The system requires fast dynamic follow-up performance and high stability speed accuracy. Therefore, we must consider the dynamic technical indicators of inverters, and select high-performance inverter to meet the requirements.

Send your message to us

VG42 High Speed Packaging Machine ( MD18 heads combination weigher)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords