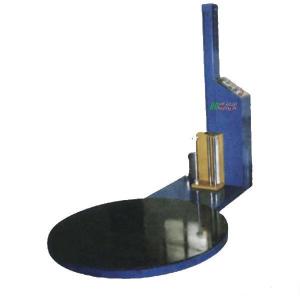

High Quality Film-Folding and Edge-Welding Machine ZBHB-101

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 days/1 set set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information High Quality Film-Folding and Edge-Welding Machine ZBHB-101

Application:

This machine can use for folding, knurl, pearl film inserting, M sharp bottom inserting and two sided glue sticking etc.

Features:

On varied of plastic films in sheets. It is equipped with frequency conversion speed adjustment motor, LPC deviation-correcting system and meter counter. This machine is the complement machine for thermal –cutting machine.

Technical Data High Quality Film-Folding and Edge-Welding Machine ZBHB-101

Max width of bag making: 600mm

Diameter of unwinding roll: Ø600mm

Diameter of winding roll: Ø500mm

Thickness of welding-cutting: 0.02mm-0.1mm

Max speed of machine: 60-100m/min

Power required: 2kw

Overall dimensions(mm): 2000 × 2000 × 1500 mm

MiinOrder: 1set

Package: Package wooden carton

Packing of High Quality Film-Folding and Edge-Welding Machine ZBHB-101

Packed with wooden carton of customized size and then placed on the pallet.

Storage Of High Quality Film-Folding and Edge-Welding Machine ZBHB-101

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Remarks of High Quality Film-Folding and Edge-Welding Machine ZBHB-101

Due to machine development, above information may be changed at any time without prior notice. The actual specifications are according to the agreement between buyer and seller.

Service of High Quality Film-Folding and Edge-Welding Machine ZBHB-101

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

- Q: The role of food packaging machinery

- (8) can promote the development of packaging machinery related industry is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, the overall performance of any discipline problems will affect the packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.Fig. 3 is a flow chart of liquid filling. With empty bottles of boxes stacked on pallets, by the conveyor belt to depalletizers, will remove the tray one by one, the box with the conveyor belt to the machine, remove the empty bottles from the box, empty by the conveying belt to the washing machine, after cleaning, and transported to the packing machine next to filled with beverage bottles into them. The empty bottles removed from the unloading machine are sent into the bottle washing machine by another conveyor belt for disinfection and cleaning. They are tested by the bottle inspection machine and conform to the cleaning standard and then enter the filling machine and capping machine. The beverage is bottled from a filling machine. Packed beverage bottle capping machine with the sealed and transported to the labeling machine labeling, (see pictures) with various beverage bottle filling line of the process is similar. But because of the different nature of beverage, the filling machine and capping machine are also different.

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- In today's world, the upgrading of packaging machinery and equipment and production lines are far ahead of Japan, which has earned a large number of dollars in this field. Southeast Asian Four Dragons also follow Japan, a heart in the performance of manufacturing packaging machinery equipment and production lines; in the European community, Italy packaging machinery equipment and production line upgrading faster than other members faster.Renewal is the means of replacing the local parts and components or key components and key technologies, so as to achieve the replacement of one of the unit, so that the original packaging machinery equipment or production line production capacity, performance, efficiency, and assembly way of updated models. In this way, most parts and machine parts are reused, which can improve the equipment value, save the raw materials and the labor force, and reduce the cost. This development trend shows that the packaging machinery, equipment and production lines are becoming more and more standardized, serialized, integrated, integrated and on-line. Civilian, military and high technology will also be more and more widely used in the field of packaging machinery equipment. Fierce market competition will undoubtedly speed up the upgrading of packaging machinery and equipment in all walks of life and technological transformation.

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: What's the best place to use the pillow type packing machine?

- In the early communication can be reflected, and sometimes non-standard customized to see the level of Technology

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: What's the fastest packing machine?

- 3 ideal speed of the package can reach 70 packs, that is, 70*3 = 210., and now there are 4 packages abroad. But the bags are small.

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Can be used to shape complex products. The principle is similar to that of injection molding. One is used for thermosetting, heating and cooling in molds, one for thermoplastic, and the other for heating in the barrel and molding cooling in the mold.

- Q: Energy saving reform of packaging machine

- First, the working principle of food packaging machinePillow type automatic packaging machine of the present domestic leading and most mature and reliable design and production technology, the essence of a collection of many years of experience in the field of packaging machinery, the packing machine can be used in a variety of composite packaging film coil on the packaging of bulk food, very suitable for the majority of users need to Chinese. 1) the electrical parts of the automatic packing machine are usually made up of the following parts:

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- English Name: Transparent, film, fold, wrapping, machineClassification: machinery, general machinery and equipment, >>J83 storage equipment, loading and unloading machineryICS classification: packing and conveying of goods, >>55.200 packaging machinery

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 11% - 30% |

| No.of Employees in Trade Department | 5-7 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | capper, adhesive sheet machine, conveting machine, rewinder machine, slitting machine, machine for protective film |

| Product Price Range | High; Average |

Send your message to us

High Quality Film-Folding and Edge-Welding Machine ZBHB-101

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 days/1 set set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords