SEMI-AUTO L BAR SEALER and SHRINK TUNNEL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

This machine is made of shrink tunnel and sealing machine. Adopt L bar manually sealing, then automatically transit to the shrink chamber and finish the shrinking

Anti-stick high-temperature alloys L type sealing knife which can seal neatly, without cracking, coking and smoking; The sealing blade with Teflon non-stick coating layer makeshift non-sticking.

It is easy to adjust the conveyor height by the hand wheel;

Control the sealing time by time relay;

Sliding bracket can be placed all kinds of shrink film, while the punching device is smooth;

The whole sealing function of SF-20LG/B is automatically completed by cylinder which decreases labor intensity and increases working efficiency;

Sealing knife with automatic anti mistakenly cutting and anti-overheating protection device effectively protect the operator away from accidental cutting;

With emergency stop device in case of emergency situations can immediately stop the machine running;

Imported electrical components assure stable performance;

Imported heat – resistant insulation curtain greatly reduces heat loss;

Stainless steel heating elements makes warming-up fast. Large power fan motor assures big wind volume and air transported uniform. According to products’ sizes and output, you can adjust conveyor speed and chamber temperature to achieve optimal contraction effect;

Using solid roller conveyor, external anti-high temperature silicone tube can endure heavier objects and rollers will become deformed;

The machine is widely used in biscuits, printing products, pharmaceuticals, floors, pottery, boxes and other packaging fields which only need one operator and conveniently working. The packing speed is fast and improves the working efficiency greatly which specially suits for bulk products packing;

Suitable for PVC, POF, PP, OPS, PET film sealing wrapping

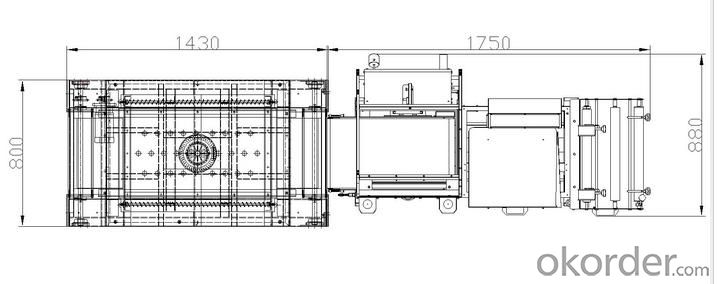

Parameters

Model | SF-20LG | SF-4525 |

Power | 1kw | 9kw |

Power Supply | AC220V 1/3PH 50/60Hz | AC220V/380 3PH 50/60Hz |

Max. Packing Size L×W×H | L+H≤530mm W+H≤430mmH≤200mm | 1000×300×200mm |

Tunnel Size L×W×H | / | 1000×450×250mm |

Table Height | 750±50mm | 850±50mm |

Packing Speed | 0-15m/min. | 0-10m/min |

Max. Loading Weight | 25kgs | 25kgs |

Shrink Film | POF,PVC | POF,PVC |

Machine Size L×W×H | 1730×790×980mm | 1300×800×1520mm |

Package Size L×W×H | 1780×840×1130mm | 1350×850×1670mm |

G./N. Weight | 155/125kgs | 320/280kgs |

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping machinery should have rolling, holding, brushing, packaging machinery, bagging, weighing, sealing.

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- China's packaging machinery and equipment manufacturing enterprises should seize this opportunity.The overall upgrading of packaging machinery equipment is the general trend of the development of packaging machinery in China and the world. The main features of the renewal is: a large number of transplanted with civilian and military industries all modern high precision technology and electronic technology, microelectronic technology, edge technology, fuzzy technology, accelerate the further improve the reliability, safety, no work of the level of automation of packaging machinery and equipment and production line. Intelligence will move into the field of packaging machinery, equipment and production lines.

- Q: Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q: The role of packaging equipment in packaging equipment

- (4) it can reduce labor intensity and improve working conditionsThe labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease.(5) labor protection for workersFor some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the packing cost and save the storage and transportation expensesFor loose products, such as cotton, tobacco, silk and hemp, the compression packing machine can reduce the volume and reduce the packing cost. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: What is the delay time of the packer's cross sealing?

- You can debug it yourself, set up a parameter, such as a delay of 1 second or a few seconds, look at the action of sealing, you know what time it is.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q: What is a packaging machine?

- Packaging machinery refers to the machinery that can complete all or part of the product and commodity packaging process. The packaging process includes filling, wrapping, sealing and other main processes

- Q: What does the mechanical equipment include?

- Rail aligning machine, rail straightening machine, grinding machineSlag shaping machine for track flat car internal combustion engine

Send your message to us

SEMI-AUTO L BAR SEALER and SHRINK TUNNEL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords