Resistance welding steel machines

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

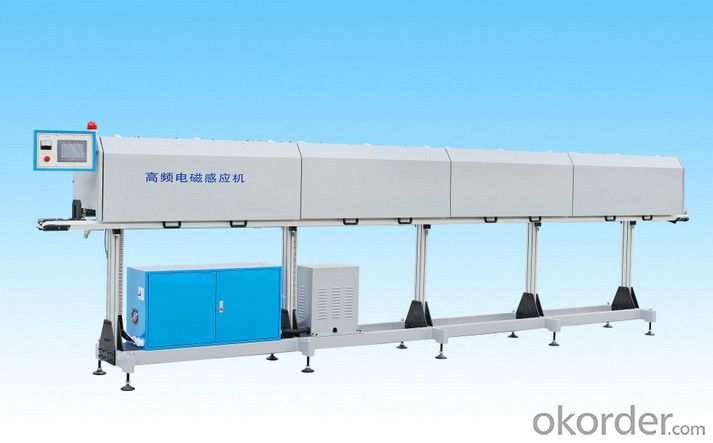

high-frequency mesh welding machine

wire mesh machine

wire diameter:4-8mm

width of mesh:1600mm

welding opening:50-300mm

fully automatic high frequency resistive welding steel reinforcing mesh machine

fully automatic wire mesh fence machine mesh welding machine welding wire machine wire mesh machine

Production of Hebei jiaoyang wire mesh machine Co.,Ltd

fully automatic high frequency resistive welding steel reinforcing mesh machine

The main parameter of high-frequency mesh welding machine

| wire diameter | 4-8mm | rated voltage | 380v |

| line wire distance | 50-200mm | rated electrical power | 8*125KVA |

| cross wire distance | 50-200mm | line wire form | coil |

| number of electrodes | 32 | cross wire form | coil |

| welding speed | 80 times/min | dimension | 3100*40000*3000mm |

| wire mesh width | 1600mm | wire mesh length | 6000mm |

The main function of high-frequency mesh welding machine

1. This high-frequency mesh welding machine adopts synchronous control technique, both welding times and seperate by digital PLC system with touch screen.

2. so that the operation is much more intelligent, reasonable and has a compression, sub-welding characteristics.

3. The aircraft welding power is from servo motor , welding speed is much faster and more stable.

4. welding pressure is provided by Nitrogen gas spring, wich is easy to adjust quikly, and the pressure is more evenly.

5. Line wire and cross wire are fed from coils. CNC sets mesh length, automatic cutting, dropping, arresting and output, which maximized saves labor and greatly increased production.

Machine application of high-frequency mesh welding machine: Mine timbering wire mesh, construction mes, reinforced mesh.

Packaging of Hebei jiaoyang wire mesh machine Co.,Ltd

fully automatic high frequency resistive welding steel reinforcing mesh machine

1. The main high-frequency mesh welding machine is apcked by plastic

2. the spare parts is packed by wooden box.

- Q: What are the main functions of packaging machinery?

- The main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging

- Q: What are the main plastic forming processes?

- Plastic processing is a complex process, generally divided into the following processing methods:In order to improve the quality of the product and improve the molding efficiency, the pre pressing is used to press the powder or fibrous molding material into a certain shape in advance.Preheating, in order to improve the processing performance and shorten the molding cycle of molding plastics, the molding plastics are heated prior to molding.Molding in the mold to add the required amount of plastic, closed mold and exhaust, at the mold temperature and pressure to maintain a period of time, and then release mold cleaning operations

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: Working principle of packing machine

- Then, by heating the sealing part of the bag bottom sealing, again is material, the material into the packaging machine, and then sealing, finally cut off, a complete package came out, this is the working principle of small vertical packaging machine.

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: What is the delay time of the packer's cross sealing?

- There is also a delay in the end of the last movement of the machine to the beginning of the sealing action.

- Q: What are the packaging machines that use temperature control watches?

- A lot of heating machines have to use thermostat

- Q: What does the mechanical equipment include?

- Packaging equipment: packaging equipment, packaging testing equipment, packaging container manufacturing equipment, special packaging equipment, filling equipment, mechanical barcode labeling machines, multi-functional packaging machine, wrapping machine, sealing machine, filling machine, strapping machine, dryerPrinting equipment: coding, inkjet printer, offset press, digital printing machine, flexo printing machine, pad printing machine, screen printing machine, complete set of printing equipment, finishing equipment, pre press processing equipment, printing equipment, printing partsSeparation equipment: filter, filter, oil filter, filter press, purification, filtration, screening, filtration, extraction, filtration, distillation, filtration separator / centrifuge, powder separation equipmentWelding and cutting equipment: electric arc welding head electric welding solder wire welding torch torch Taiwan electrode tip plasma welder welder laser welding friction welding machine more chemical equipment heat transfer equipment, chemical equipment transfer pipeline material environmental protection equipment mixing equipment laboratory equipment pressure vessel instrument and electrical equipment reactor piping and fittings of non-metallic equipment

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

Send your message to us

Resistance welding steel machines

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords