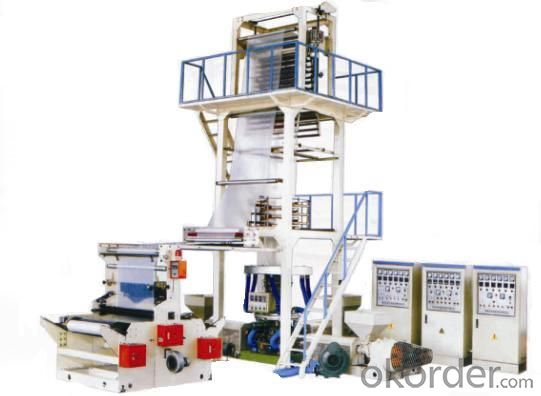

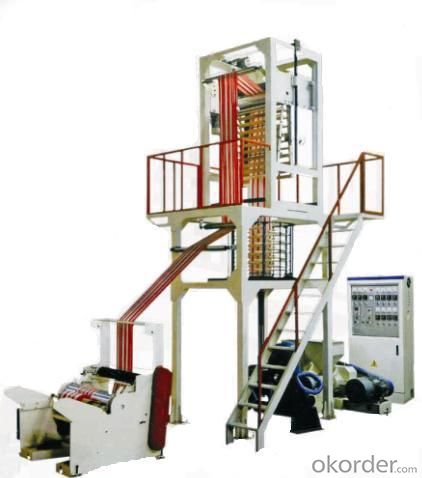

High Quality Mini Film Blowing Machine CM-M50

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 days/1 set set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information High Quality Mini Film Blowing Machine CM-M50

Its extruder, cylinder and screw rods are made of quality alloy steel that have been nitrizied and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity. It is applied to blowing the plastic films like low density polythene(LDPE), high density polythene(HDPE)and linear low density polythene(LLDPE).It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

Technical Data High Quality Mini Film Blowing Machine CM-M50

Model: CM-M50

Screw Diameter: Φ50 mm

Max.folding width of film: 100-600 mm

Single-side thickness of film(mm): 0.01-0.01 mm

Max. output: 50kg/h

Screw ratio L/D : 26:1

Main motor power (kw): 7.5-11 kw

Haul-off motor Power (kw): 1.1 kw

Heating power(kw) :11kw

Overall diameter(L×W×H)(mm) :3800×1900×3000 mm

Weight(T) : 1.5T

MiinOrder: 1set

Package: Package wooden carton

Packing of High Quality Mini Film Blowing Machine CM-M50

Packed with wooden carton of customized size and then placed on the pallet.

Storage Of High Quality Mini Film Blowing Machine CM-M50

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Remarks of High Quality Mini Film Blowing Machine CM-M50

Due to machine development, above information may be changed at any time without prior notice. The actual specifications are according to the agreement between buyer and seller.

Service of High Quality Mini Film Blowing Machine CM-M50

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

- Q: Bread packing machine Product features

- Bread packing machine, also commonly known as pillow type packaging machine. Among them, the suitable packing bread model has CM-320 pillow type packing machine, CM-400 pillow type bread packing machine

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- In today's world, the upgrading of packaging machinery and equipment and production lines are far ahead of Japan, which has earned a large number of dollars in this field. Southeast Asian Four Dragons also follow Japan, a heart in the performance of manufacturing packaging machinery equipment and production lines; in the European community, Italy packaging machinery equipment and production line upgrading faster than other members faster.Renewal is the means of replacing the local parts and components or key components and key technologies, so as to achieve the replacement of one of the unit, so that the original packaging machinery equipment or production line production capacity, performance, efficiency, and assembly way of updated models. In this way, most parts and machine parts are reused, which can improve the equipment value, save the raw materials and the labor force, and reduce the cost. This development trend shows that the packaging machinery, equipment and production lines are becoming more and more standardized, serialized, integrated, integrated and on-line. Civilian, military and high technology will also be more and more widely used in the field of packaging machinery equipment. Fierce market competition will undoubtedly speed up the upgrading of packaging machinery and equipment in all walks of life and technological transformation.

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q: The role of packaging equipment in packaging equipment

- (4) it can reduce labor intensity and improve working conditionsThe labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease.(5) labor protection for workersFor some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the packing cost and save the storage and transportation expensesFor loose products, such as cotton, tobacco, silk and hemp, the compression packing machine can reduce the volume and reduce the packing cost. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.

- Q: What is the delay time of the packer's cross sealing?

- There is also a delay in the end of the last movement of the machine to the beginning of the sealing action.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 11% - 30% |

| No.of Employees in Trade Department | 5-7 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | capper, adhesive sheet machine, conveting machine, rewinder machine, slitting machine, machine for protective film |

| Product Price Range | High; Average |

Send your message to us

High Quality Mini Film Blowing Machine CM-M50

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 days/1 set set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords