PVC Ceiling Walls for Ceiling and Wall in Hotels and Commercial Buildings

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Price Terms : FOB/CIF

Payment term : 30% prepayment , 70% before shipment

Supply Ability : 15 produce line , 17000M2each day , 20 *40 HQ /month

Minimum Order : one 20 container

Product Advantages:

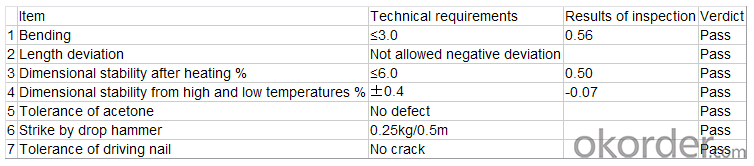

Specification | Thickness(mm) | Width(cm) | Weight(kg/m2) |

6 | 18 | 1.8 | |

5 | 20 | 1.6 | |

6 | 20 | 1.8 or 2.0 | |

6 | 25 | 1.8 or 2.0 | |

6.75 | 25 | 2.4 | |

7 | 20 | 2.0 or 2.3 | |

7 | 59.5 | 2.5 | |

7 | 60.3 | 2.5 or 3.0 | |

7.5 | 25 | 2.4 | |

8 | 20 | 2.5 or 2.625 | |

8 | 25 | 2.3 or 2.5 | |

8 | 16 | 3.125 | |

8.5 | 20 | 2.5 or 3.5 | |

9 | 20 | 3.0 or 3.15 | |

9 | 30 | 2.95 or 3.085 or 3.16 | |

9 | 25 | 3.2 | |

9.5 | 30 | 3.9 or 4.0 | |

9.5 | 10 | 3.5 or 4.0 | |

9.5 | 16 | 3.3 or 3.75 | |

9.5 | 20 | 2.625 or 3.5 or 3.75 or 4.125 | |

9.5 | 6 | 5.3 | |

11 | 20 | 4.4 | |

12 | 15 | 3.0 | |

12 | 20 | 3.9 | |

13 | 20 | 4.375 | |

15 | 20 | 4.75 | |

Length: 5.8m for 20'GP and 5.95m for 40'HQ. or according to customer requirement. | |||

Main Product Features:

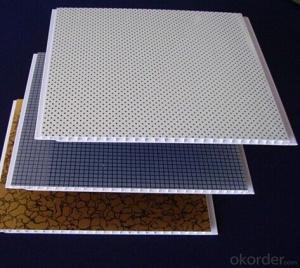

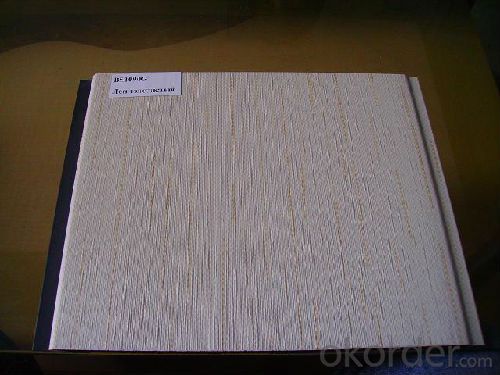

1)Glossy PVC Panel (most common type)

2)Sub-glossy PVC Panel (Natural surface handing)

3) High-glossy PVC Panel (high-light surface handling)

Product Specifications:

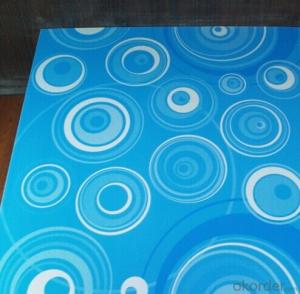

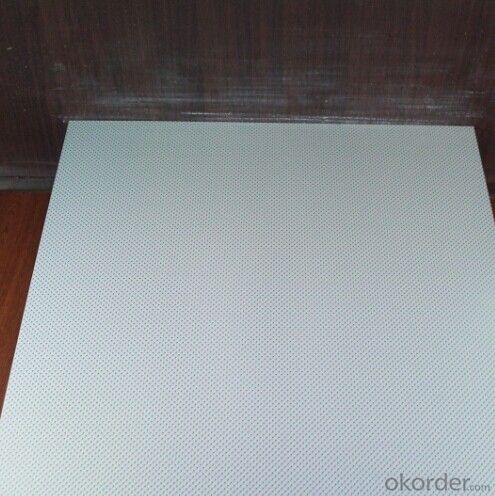

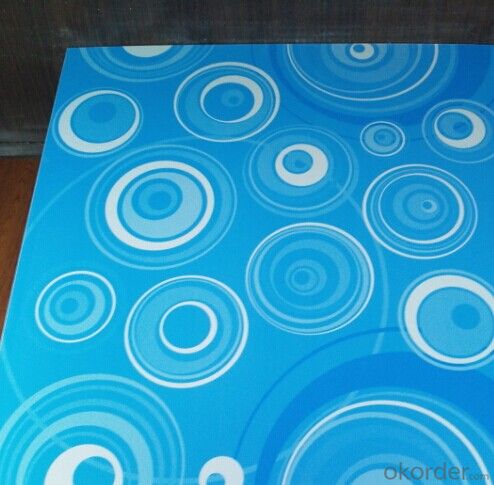

Images:

- Q: How to pack the decoration pipe

- There are three general ways: 1, with pvc button board package. Cheap, easy construction, beautiful, life is not long. 2, with wooden keel backing, on the woodworking board, the last paste aluminum plate. 3, with 8 * 5 red brick puzzle, cement mortar, sticky steel mesh, and finally paste the tiles. More than 2,3 to be in the place where the need for inspection mouth.

- Q: Wood-plastic board, PVC board, science and technology What is the difference between wood?

- Wood-plastic board is made of wood fiber mixed polymer plastic after extrusion molding, is an environmentally friendly material, its weather resistance is very good, generally used for outdoor decoration. Pvc board is made of pvc material of a material, it is light weight, have a certain strength, but the weather resistance of acid and alkali difference for product packaging and interior decoration. Science and technology wood is made of artificial veneer made of decorative panels, generally with no color, pattern and other natural decorative panels can not achieve the decorative effect, but its pattern rigid, color frivolous no less than the natural decorative panel texture and decorative grade.

- Q: Pvc board how to buckle indoor wall skirt

- Replenishment is actually everyone needs to do, but also to maintain a normal operation of the human body the best way: 1, but at the same time pay is very emphasis on the method, because the intercellular stroma between the human body is a channel, the channel is allowed to pass through the water after the water can be directly into the body to fill the water, this type of water we Called small molecule water. 2, and the general water does not have this effect, a lot of macromolecules can not directly enter the human body, so that not only can not play the role of replenishment, but also have a reaction, stay in the extracellular adsorption of impurities in the body, so Not only can not play the role of water, but also play a reaction.

- Q: Sun room,studded partition over the windows, pvc on the exterior. Losing heat? What can I do? Tiled roof?

- No hopefully I wouldn't be daft enough to do that. I don't have a sun roof but I can just imagine how stupid you would feel stuck there with no way out!

- Q: What kind of plastic plate does the water tank make

- PVC or PP material, PP plasticity is better, but the relative price is more expensive.

- Q: What is the difference between KT board and PVC foam board? Which is used in the subway transfer channel (pictured) advertising material?

- In general, such a big board when the board is KT board, KT board is very light, but also cheap, generally 1 meter 2 two meters 4 specifications, 5mm thickness, soft, utility knife can easily cut , Easy to cut, stitching, this figure in the board should be KT board. PVC foam board is a hard material, relatively thick, with a variety of thickness, 1 cm thick and also 4,5 mm thick, it is in advertising, mainly for carving, such as the company on the back of the wall Sign ah, the word ah what, usually for the beautiful above will add a layer of acrylic, there are all with acrylic, but the acrylic is more expensive, so the request is not too high, then use PVC instead, the above can also be mounted on the screen.

- Q: How to judge the true and false PVC board?

- True and false PVC to determine: you can take a small amount of PVC board with a flame burning, if a large number of black smoke, and accompanied by pungent smell of hydrogen chloride, the flame after the burning surface was black charcoal, the basic can be concluded that PVC; Not associated with a lot of black smoke, no irritating smell, and the flame after the burning surface was white or light white, it may be polyethylene or polypropylene plate.

- Q: What is the difference between pvc floor and marble floor?

- Anti-static PVC floor is in the PVC floor components added conductive material made of anti-static floor. But this is not simply add some toner can be, anti-static floor in the resistance value has a strict distinction. The general resistance of 10 in the 6 to 10 of the 9 times between the floor is called anti-static floor, the resistance in the 10 to 4 of the 6 to 6 times between the called conductive floor. Anti-static floor is mainly used for the engine room, special wards, precision workshops and some special requirements for static space. So that anti-static PVC flooring is a kind of PVC floor. But the rubber floor to join some conductive components can also be anti-static.

- Q: What is the difference between acrylic and PVC? Which is relatively better?

- Acrylic better, you can light, the price is higher PVC easy to crack, fade, prone to scratches, the price is cheaper

- Q: PVC door cut how bad repair

- PVC door repair has a special fill ash putty, make a good gray after the polished smooth And then use the same color paint spray paint treatment Generally more well-known brands will have material processing

Send your message to us

PVC Ceiling Walls for Ceiling and Wall in Hotels and Commercial Buildings

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords