Double-strand PVC Pipe Extrusion/Production Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

The production line is mainly used in the production of PVC pipe,The producing line can be adjusted according to clients' requirements .

What's more, the line can work at high capacity and be easy to maintain.

Nomally this line is composed by eight parts ,as follow:

1. Feeder

2. conical twin-screw extruder

3. pipe mould

4. vacuum calibration tank

5. Spraying box

6. haul-off

7. cutter

8. staker

The mixer can also be equiped by requirement .

Machine Application

Such qualified extrusion line is mainly for producing PVC agricultural water/ building water/cable pipes, etc.

It can process various soft and rigid PVC, especially process powder directly into pipe shape.

Whole line consists of material feeder, conical twin screw extruder, die head, vacuum calibration tank, haul-off, cutter, stacker or belling machine, etc.

Machine List

| No. | Item | Qty |

| 1 | Screw feeder | 1 set |

| 2 | SJZ 80/156 Conical twin screw extruder | 1 set |

| 3 | Die head | 1 set |

| 4 | Vacuum calibration tank | 1 set |

| 5 | Three claws haul-off | 1 set |

| 6 | Planetary cutter | 1 set |

| 7 | Stacker | 1 set |

| Option | Belling Machine | 1 set |

Annotation: Some configuration and material can be designed according to customers’ requirement. | ||

Improvements made on Conical twin screw extruder:

1.Gear box bearings: NSK, Japan

2.Gear box: Jiangyin Brand

3.Special design of screw & barrel

4. All connector, nut etc all adopt nickel plated

Technical Data

Extruder | Pipe ranger (mm) | Max.output (kg/h) | Max.hauling speed (m/min.) | Extruder powder (KW) |

CAMX51/105 | 16-40 Dual | 120 | 10 | 18.5AC |

CAMX65/132 | 20-63 Dual | 250 | 15 | 37AC |

CAMX51/105 | 20-63 | 120 | 15 | 18.5AC |

CAMX65/132 | 50-160 | 250 | 8 | 37AC |

CAMX65/132 | 63-200 | 250 | 3.5 | 37AC |

CAMX80/156 | 160-315 | 350 | 3 | 55AC |

CAMX92/188 | 315-630 | 800 | 1.2 | 110DC |

ITEM | BRAND | |

1 | Motors | Famous brand in China |

2 | PLC | SIMENS 200 series |

3 | Interface module | SIMENS |

4 | Touch screen | SIMENS (10 inch) |

5 | Low voltage electrical equipments | SIMENS&SCHNEIDE |

6 | Inverter | ABB |

7 | Temperature control system | OMRON |

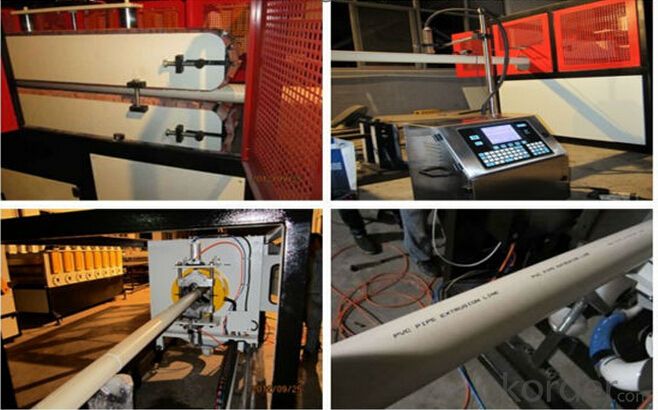

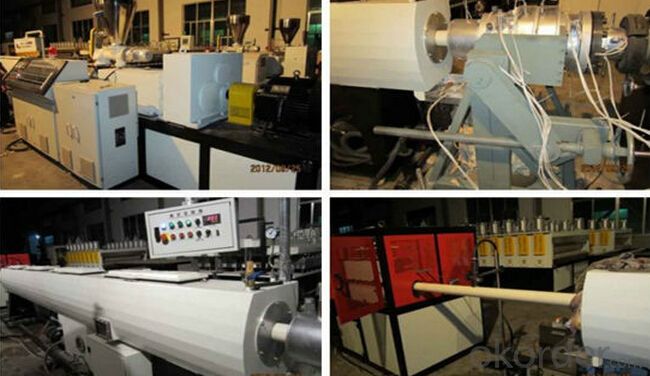

Product picture

FAQ:

Q: What price terms you offer?

A: FOB, CIF, EXW, L/C at sight and other price terms based on your kind request.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Tangqiao Town, Zhangjiagang City, Jiangsu Province, China. About 2.5 hours from Shanghai Pudong International Ariport! We will arrange to pick you up from Shanghai.

A: Yes, our engineers will guide machine installation and train your workers.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

- Q: extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Is the place where the material is easy to burn rough? Add stabilizers and lubricants appropriately.

- Q: Produce 10 square wires with the smallest extruder

- If it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: What are the common extrusion molding products?

- A plastic pipe, including water supply and drainage pipe, casing and other electrical B plastic doors and windows just C a variety of wire, cable, cable break, also includes a data line, wire headset D PVC ceiling e for plastic guardrail protection f roadside flowers and some decorative strips, temporary thought so much, there are a lot of specific products and you look at the things around you can think of

- Q: Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q: Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- Proposed Delta VFD-cp Series ~!AskCP2000 is constant pressure water supply... Are you sure you can use it? And C2000 is better than qualifiedChasing the answerWrong number ~ ~ should be C2000, and VE Series ~ ~ these two are suitable, ~~B, CP is not good ~!

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- 1. injection molding2., the structure is relatively complex, high appearance requirements. Extrusion does not meet requirements3. most are: ABS, ABS+PC, PP and so on4., according to color requirements granulation - drying particles - filling the mold ---- debugging injection molding machine ---- injection molding production - after the selection of finished packaging (if silk screen requirements, but also the need for silk screen)

- Q: Extrusion machine operating procedures, specific points, thank you!

- 1, operators must be familiar with the procedures, the safety test qualified, wear good protective equipment, shall operate the equipment.2 when the power is on, check whether the thermal control of the electric appliance is sensitive and reliable, whether the thermocouple indicates the temperature is correct or not, and if there is a problem, please repair the personnel to exclude them.3 when driving, should check the main reducer, traction non polar transmission, the line is stepless gear box lubrication is normal, fan ventilation is good.4 before driving, pay attention to the heating temperature of each section, whether the actual temperature required by the process, the heat preservation time should be enough, and the initial heating time can not be less than 3 hours heat preservation.5, not in the plastic bad, scorched, aging, extrusion production, in case of accidents, and found the above problems, immediately try to rule out.

- Q: How to adjust the 65 screw gap in the extruder?

- This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- How big is it? Not too big. I suggest using a 40 or 30 too big block. You have to use a special break knot.

- Q: Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- Adjust the main speed buttonAskI've changed the line.

Send your message to us

Double-strand PVC Pipe Extrusion/Production Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords