Unequal Angle Steel Hot Sale High Tensile China Prime Small GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | angle steel packed in bundle or as customer's requirements. |

| Delivery Detail: | 10-30 days after customer placed the angle steel order |

Specifications

gb standard unequal angle steel

1.high dimensional accuracy

2.beauty appearance

3.save 28%-30% raw materials

4.BV

Details of Angle steel

| Name | Angle steel |

| Standard | AISI, ASTM, BS,DIN,GB,JIS |

| Grade | A36, SS400, Q235, Q345, S235,S275 |

| Dimensions | 25*3-200*20 |

| Length | 6-12m |

| Technique | Hot rolled steel angle bar |

| Tolerance | As the standard or as your requirement |

| Surface treatment | Galvanized, paint |

| Application | Metal structure, bridge, machiner, shipbuilding industry |

| Certificated | BV |

| Packing details | standard export packing or as your requirement |

| MOQ | 5 tons |

| Delivery | Within 25 days after deposit |

| Payment | T/T or L/C |

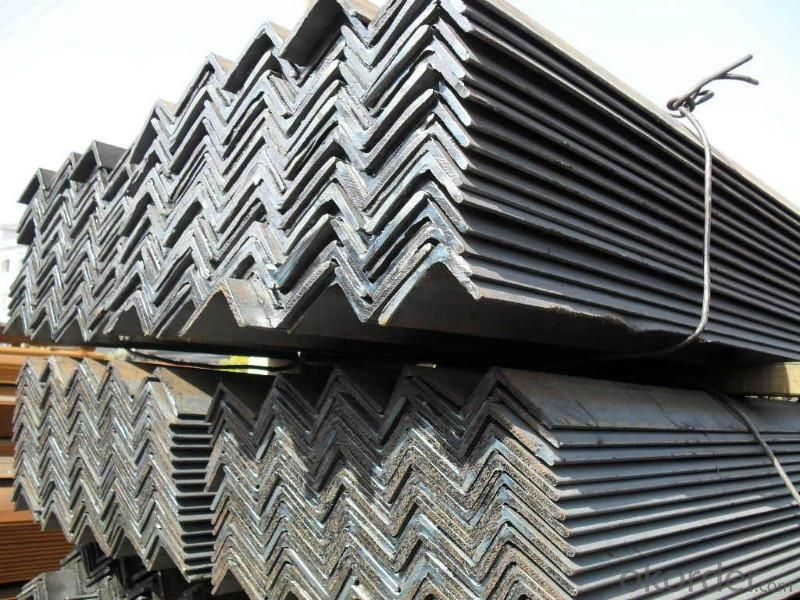

Advantage of Angle steel

1.Convenient in construction and save much time and labor

2.High mechanical strength

3.Low price, high quality

Size of Angle steel

| Equal angle(A*T) | |||||

Size (mm) | Theoretical weight (kg/m) | Size (mm) | Theoretical weight (kg/m) | Size (mm) | Theoretical weight (kg/m) |

| 25*3 | 1.124 | 75*7 | 7.976 | 110*14 | 22.809 |

| 25*4 | 1.459 | 75*8 | 9.03 | 125*8 | 15.504 |

| 30*3 | 1.373 | 75*10 | 11.089 | 125*10 | 19.133 |

| 30*4 | 1.786 | 80*6 | 7.376 | 125*12 | 22.696 |

| 40*3 | 1.852 | 80*7 | 8.525 | 125*14 | 26.193 |

| 40*4 | 2.422 | 80*8 | 9.658 | 140*10 | 21.488 |

| 40*5 | 2.976 | 80*10 | 11.874 | 140*12 | 25.522 |

| 50*4 | 3.059 | 90*6 | 8.35 | 140*14 | 29.49 |

| 50*5 | 3.77 | 90*7 | 9.658 | 140*16 | 35.393 |

| 50*6 | 4.465 | 90*8 | 10.946 | 160*10 | 24.729 |

| 60*5 | 4.52 | 90*10 | 13.476 | 160*12 | 29.391 |

| 60*6 | 5.42 | 90*12 | 15.94 | 160*14 | 33.987 |

| 63*5 | 4.822 | 100*6 | 9.366 | 160*16 | 38.518 |

| 63*6 | 5.721 | 100*7 | 10.83 | 180*12 | 33.159 |

| 63*8 | 7.469 | 100*8 | 12.276 | 180*14 | 38.518 |

| 63*10 | 9.151 | 100*10 | 15.12 | 180*16 | 43.542 |

| 70*5 | 5.397 | 100*12 | 20.611 | 180*18 | 48.634 |

| 70*6 | 6.406 | 100*16 | 23.257 | 200*14 | 42.894 |

| 70*7 | 7.398 | 110*7 | 11.928 | 200*16 | 48.68 |

| 70*8 | 8.373 | 110*8 | 13.532 | 200*18 | 54.401 |

| 75*5 | 5.818 | 110*10 | 16.69 | 200*20 | 60.056 |

| 75*6 | 6.905 | 110*12 | 19.782 | ||

gb standard unequal angle steel

- Q: How do you prevent warping of steel angles during fabrication?

- To avoid warping of steel angles during fabrication, there are several important measures that can be implemented: 1. Careful handling of materials: It is crucial to handle steel angles with care to prevent bending or warping. They should be stored on a flat surface or rack, ensuring they are not subjected to excessive pressure or force that could cause deformation. 2. Control of heating and cooling: When heat is involved in fabrication processes like welding or cutting, temperature control and minimizing heat input are key. Rapid heating or cooling can lead to thermal expansion or contraction, resulting in warping. It is important to use proper preheating and controlled cooling methods, such as heat sinks or heat treatment processes, to mitigate this risk. 3. Use of proper welding techniques: Welding plays a vital role in steel fabrication, and using incorrect techniques can contribute to warping. It is essential to employ appropriate welding parameters, such as amperage, voltage, and travel speed, to ensure even heat distribution across the workpiece. Additionally, utilizing welding fixtures, clamps, or jigs can help secure the steel angles during welding, minimizing distortion. 4. Reduction of stress concentration: Sharp corners or sudden changes in geometry can create points of stress concentration, which are prone to warping. It is advisable to avoid sharp corners by incorporating radii or chamfers, as these distribute stress more evenly. Furthermore, ensuring proper alignment and fit-up of the steel angles before welding can reduce residual stress and the potential for warping. 5. Implementation of post-welding treatments: After welding, it is crucial to relieve any residual stresses present in the steel angles. This can be achieved through post-weld heat treatment or stress-relieving processes, such as annealing or normalizing. These treatments help reduce internal stresses and minimize the risk of warping. Overall, a combination of careful material handling, controlled heating and cooling, proper welding techniques, stress reduction, and post-welding treatments can greatly contribute to the prevention of warping during the fabrication of steel angles.

- Q: Can steel angles be used as supports for HVAC systems or ductwork?

- Yes, steel angles can be used as supports for HVAC systems or ductwork. Steel angles are commonly used in construction and engineering projects due to their strength and durability. They can provide a stable and secure support structure for HVAC systems or ductwork, ensuring that they are properly installed and can withstand the weight and vibrations associated with their operation. Steel angles can be easily fabricated and installed, making them a cost-effective and efficient solution for supporting HVAC systems or ductwork.

- Q: Are steel angles susceptible to rusting?

- Yes, steel angles are susceptible to rusting.

- Q: How do you determine the appropriate size of steel angle for a specific application?

- To determine the appropriate size of steel angle for a specific application, factors such as the load it needs to bear, the length of the span, the type of material being supported, and any applicable building codes or regulations should be considered. Structural engineers or professionals with expertise in steel construction can perform calculations and analysis to determine the required size of steel angle based on these factors.

- Q: Do steel angles come with any warranties?

- Yes, steel angles typically come with warranties. The specific warranty terms may vary depending on the manufacturer or supplier. However, most reputable companies offer warranties to ensure the quality and performance of their steel angles. These warranties typically cover defects in materials or workmanship and may range from a few months to several years. It is advisable to check the warranty terms and conditions provided by the manufacturer or supplier before purchasing steel angles to understand the extent and duration of the warranty coverage.

- Q: What are the common defects or issues found in steel angles?

- Steel angles can experience various defects or issues that impact their structural integrity and performance. The most common ones include: 1. Surface imperfections: Scratches, pits, or uneven coating may be present on steel angles. While these may not affect the angle's strength significantly, they can impact its appearance and corrosion resistance. 2. Warping: Steel angles can bend or distort along their length, either during manufacturing or as a result of improper handling or storage. Warped angles may not fit properly in applications that require precise dimensions. 3. Dimension flaws: Steel angles should adhere to specific dimensions and tolerances. However, defects like undersized or oversized legs, unequal lengths, or inconsistent thickness can occur. These flaws can cause installation issues or compromise the angle's structural integrity. 4. Lack of straightness: Steel angles should be straight along their entire length to ensure proper alignment and load distribution. However, they can sometimes exhibit a lack of straightness, known as bowing or crooking. This defect makes it difficult to accurately align angles and may result in uneven stress distribution. 5. Internal cracks: Cracks inside the steel angle are a major concern as they weaken its strength and load-bearing capacity. These cracks can occur during manufacturing due to improper cooling or quenching processes, or they can be a result of excessive stress or corrosion. Internal cracks are often invisible to the naked eye, necessitating non-destructive testing methods like ultrasound or magnetic particle inspection. 6. Corrosion: Steel angles are prone to corrosion, particularly in high humidity or chemical exposure environments. Corrosion weakens the structure and affects the angle's performance. Regular maintenance and appropriate protective measures are necessary to prevent or minimize corrosion-related defects. Prompt identification and addressing of these defects or issues are crucial to ensuring the safety and reliability of steel angles in various applications. Regular quality checks, adherence to industry standards, and proper maintenance practices help mitigate these problems and ensure the durability of steel angles.

- Q: Can steel angles be used for manufacturing door frames?

- Indeed, door frames can be manufactured using steel angles. In construction, steel angles are frequently employed owing to their robustness and endurance. They offer structural reinforcement and can be effortlessly joined via welding or bolting to create a solid frame. Moreover, steel angles possess the added benefit of being resistant to corrosion, a crucial feature for door frames that are exposed to the elements. Furthermore, steel angles can be tailored to precise measurements and shapes in order to suit the desired design and dimensions of the door frame. All in all, steel angles are a trustworthy and widely favored option for door frame fabrication.

- Q: Are steel angles resistant to earthquakes?

- Seismic-resistant construction can be achieved by utilizing steel angles, which possess high strength and ductility, making them suitable for this purpose. Often referred to as steel L-shaped beams, these steel angles are commonly employed in structural applications to provide support and reinforcement. During an earthquake, the utilization of steel angles aids in the even distribution of seismic forces throughout the structure, thereby reducing the occurrence of concentrated stress points. The L-shape design of these steel angles allows them to effectively resist bending and twisting forces, which are frequently encountered during seismic events. Moreover, steel angles can be interconnected and welded together to establish a rigid frame system, thereby enhancing their capability to withstand seismic forces. Such a system effectively absorbs and dissipates energy resulting from vibrations caused by earthquakes, ultimately minimizing any potential damage inflicted upon the structure. Nevertheless, it is crucial to acknowledge that the overall seismic resistance of a structure is contingent upon several factors, including its design, construction methods, and adherence to building codes and regulations. While steel angles alone cannot ensure complete protection against earthquakes, their integration into a well-designed seismic-resistant system significantly augments the structure's capacity to withstand seismic forces.

- Q: What is the process of cold bending steel angles?

- The process of cold bending steel angles involves manipulating the angles into a desired shape without the use of heat. This is done by applying force or pressure to the angles in a controlled manner. First, the steel angle is secured in a bending machine or fixture that can hold it securely in place during the bending process. The operator then determines the desired angle and bend radius, which determines the amount of force that needs to be applied. Next, the bending machine or fixture applies pressure to the steel angle, gradually bending it to the desired shape. The force is typically applied slowly and evenly to prevent any deformation or damage to the steel. During the bending process, it is important to monitor the angle and ensure that it is bending evenly and smoothly. The operator may need to make adjustments to the pressure or angle of the bending machine to achieve the desired shape. Once the steel angle has been bent to the desired angle, it is carefully removed from the bending machine or fixture. It is important to handle the bent angle with care to prevent any distortion or damage. Cold bending steel angles offers several advantages over hot bending, such as reduced risk of material distortion or weakening due to heat. It also allows for more precise and controlled bending, making it suitable for a wide range of applications where accuracy is crucial. Overall, the process of cold bending steel angles involves securely positioning the angle in a bending machine or fixture, applying gradual and controlled pressure to bend it to the desired shape, and carefully removing the bent angle for further use.

- Q: How do steel angles perform in terms of energy efficiency?

- Steel angles can be an energy-efficient option depending on their design and application. The energy efficiency of steel angles primarily depends on factors such as the type and thickness of the steel used, the manufacturing process employed, and the installation techniques. One aspect that contributes to the energy efficiency of steel angles is their thermal conductivity. Steel, being a conductive material, can transfer heat quickly, which can be advantageous in certain applications. For instance, steel angles can efficiently conduct heat away from building components in cooling systems, helping to maintain desired temperature levels and reduce energy consumption. Furthermore, steel angles can be designed to optimize their structural performance, reducing the need for additional materials or construction methods. This can result in lower energy usage during the manufacturing and installation processes. Additionally, steel angles can be recycled, making them an environmentally friendly choice. The energy required to recycle steel is significantly lower compared to producing it from raw materials. This reduces the energy demand and greenhouse gas emissions associated with steel production. However, it is important to note that the overall energy efficiency of steel angles also depends on their application and the overall design of the structure. Proper insulation, sealing, and design considerations are crucial to ensure optimal energy efficiency. It is recommended to consult with professionals and engineers to determine the most efficient use of steel angles in specific projects. In conclusion, steel angles can offer energy-efficient solutions when used appropriately. By considering factors such as thermal conductivity, structural optimization, and recyclability, steel angles can contribute to reducing energy consumption and promoting sustainability in various applications.

Send your message to us

Unequal Angle Steel Hot Sale High Tensile China Prime Small GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords