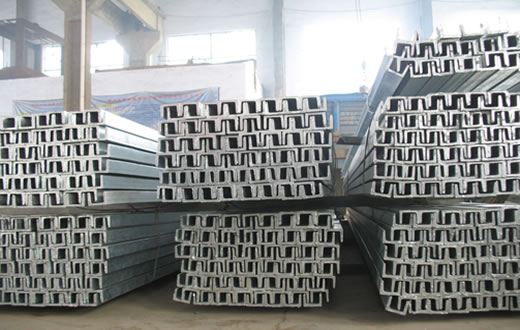

U CHANNEL JIS U CHANNEL OR GB Q235 Q345B Hot Rolled

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality U CHANNEL JIS U CHANNEL OR GB Q235 Q345B Hot Rolled at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1.The JIS U Channel Steel can be devided into two kinds, namely common channel steel and light channel steel. The sizes of hot rolled common channel steel range from 5# to 40#. Meanwhile, the channel steel can be divided into cold forming sectional equal channel steel, cold forming sectional unequal channel steel, cold forming inner edge channel steel and outer edge channel steel.

2.The JIS u channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. The channel steel with sizes under 14# is usually applied to construction engineering, as purline, while the channel steel with sizes above 16# is more likely to be used in building vehicle chassis structure and mechanical structure. Furthermore, the channel steel in sizes above 30# are target at building bridge structure, as tension bar.

3.In a word, the channel steel must possess perfect welding property, riveting property and mechanical property and so on.

Product Advantages:

OKorder's U CHANNEL JIS U CHANNEL OR GB Q235 Q345B Hot Rolled are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Original Place | Tangshan, China | Brand Name | UINDA |

Standard | JIS G3192 : 1990 | ||

Material Grade | SS490 | ||

Sizes | 50mm to 200mm | ||

Sales Volume/Year | 3000MT | ||

Destination Area | Middle East, Africa, Southeast Asia | ||

2. The sections in details are as followings in the table-1

JIS U CHANNEL | Standard | Sectional | Dimension |

| Mass: |

| (mm) | (mm) | (mm) | (mm) |

|

50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

|

|

|

|

|

|

100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

|

|

|

|

|

|

125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

|

|

|

|

|

|

150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

150x75 | 150 | 75 | 6.5 | 10.00 | 24.00 |

|

|

|

|

|

|

200X80 | 200 | 80 | 7.5 | 11.00 | 24.60 |

3. The mechanical property of JIS U Channel Steel in the table-2:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

4. The chemical composition of JIS U Channel Steel as per SS490 in the table-3

Grade | Element(%) | |||

C | Mn | P | S | |

SS490 | - | - | ≦0.050 | ≦0.050 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3 Can stainless steel rust?

A3 Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: What are the factors that affect the price of steel channels?

- The price of steel channels can be influenced by various factors. Let's explore some of these factors: 1. Raw material costs play a significant role in determining the price of steel channels. The cost of materials like steel, iron ore, and coal directly affects the manufacturing cost of steel channels. Fluctuations in these raw material prices can, in turn, impact the final price of the channels. 2. Supply and demand dynamics also have an impact on steel channel prices. When demand for steel channels is high and the supply is limited, prices tend to rise. Conversely, if demand is low and there is excess supply, prices are likely to decrease. 3. Manufacturing and processing costs, including expenses related to labor, energy, and equipment, can influence the price of steel channels. Higher manufacturing costs may result in higher prices for the channels. 4. The level of competition among steel channel manufacturers can also affect prices. When multiple producers offer similar products, they may engage in price competition to attract customers, leading to lower prices. On the other hand, if there are fewer suppliers or if they offer unique products, prices may be higher. 5. Transportation and logistics costs can impact the final price of steel channels. Factors such as fuel prices, shipping distances, and transportation infrastructure all contribute to transportation costs, which can be passed on to the buyer. 6. Government regulations and tariffs are another factor that can influence steel channel prices. Trade policies, import duties, and government regulations can increase the price of imported steel channels, while subsidies or support from the government can lead to lower prices. 7. Economic conditions, both globally and domestically, have an impact on steel channel prices. Economic growth, inflation, and currency exchange rates can all influence the cost of steel channels. It is important to understand that these factors are interconnected and can vary depending on market dynamics and location. Therefore, buyers and sellers in the steel channel industry must consider these factors and their potential impact.

- Q: What are the different types of steel channel connections used in industrial buildings?

- Industrial buildings commonly utilize various types of steel channel connections, which serve as essential components for ensuring structural strength, stability, and load-bearing capacity. Some of the frequently employed steel channel connections in industrial buildings are as follows: 1. Bolted Connections: One of the most prevalent types of steel channel connections involves the utilization of bolts to connect the channels together. Bolted connections facilitate easy installation and can be readily disassembled or modified if necessary. These connections are renowned for their exceptional strength and reliability. 2. Welded Connections: Welding is another extensively employed method for joining steel channels in industrial buildings. This technique involves fusing the channels together using heat, resulting in a robust and permanent connection. Welded connections are esteemed for their superior strength and rigidity. They are often favored in applications that demand structural integrity and significant load-bearing capacity. 3. Riveted Connections: Riveting is a traditional approach to connecting steel channels, wherein rivets are employed to join the channels together. Riveted connections offer remarkable strength and durability. However, their installation requires specialized equipment and expertise, which renders them less common in modern industrial buildings. 4. Cleat Connections: Cleat connections find frequent usage when connecting steel channels to other structural members like beams or columns. A cleat, which can be a steel plate or angle, is bolted or welded to the channel, securely attaching it to the adjacent member. Cleat connections provide a reliable and efficient means of joining different components within an industrial building. 5. Gusset Plate Connections: Gusset plate connections are employed to connect steel channels at intersection or joint points. A gusset plate, typically made of steel, is bolted or welded to the channels, imparting additional strength and stability to the connection. These connections are commonly observed in truss systems and other load-bearing applications. It is imperative to acknowledge that the selection of a specific type of steel channel connection for an industrial building depends on various factors, such as the structural design, load requirements, and construction methods. Seeking consultation from a structural engineer or construction professional is vital to determine the most suitable connection type for a given application.

- Q: Can steel channels be used in shipbuilding?

- Indeed, shipbuilding incorporates the utilization of steel channels. Due to their robustness, longevity, and adaptability, steel channels are widely employed in ship construction. These channels serve as a reliable source of structural support and find application in various tasks such as framing, stiffening, and reinforcing different sections of the ship's hull and superstructure. Specifically designed to endure the adverse conditions encountered at sea, including wave impact, corrosion, and extreme temperatures, steel channels prove their resilience. Additionally, their weldability facilitates efficient assembly and repair procedures. In summary, steel channels constitute a vital element in shipbuilding, playing a critical role in upholding the vessel's strength and integrity.

- Q: What are the different design considerations for steel channels in high-rise buildings?

- There are several important design considerations for steel channels in high-rise buildings. Firstly, the load capacity of the channels must be carefully calculated to ensure they can withstand the vertical loads from the weight of the building and its occupants. Additionally, the channels must be designed to resist lateral loads such as wind and seismic forces. Fire resistance is another crucial consideration, with channels often requiring special coatings or fireproofing materials. The channels must also be designed to accommodate any necessary connections with other structural elements, such as beams or columns. Finally, factors such as the size and shape of the channels, as well as their corrosion resistance, must be taken into account to ensure the overall structural integrity and longevity of the building.

- Q: How do steel channels contribute to sound insulation?

- Steel channels can contribute to sound insulation by providing a rigid structure that helps to minimize the transmission of sound waves. When steel channels are used in the construction of walls or ceilings, they create a framework that can be filled with sound-absorbing materials such as insulation or acoustic panels. This combination of the steel channels and sound-absorbing materials helps to dampen and absorb sound energy, reducing the amount of noise that can pass through the structure. Additionally, steel channels can also be used to create double or staggered wall systems, which further enhances sound insulation by creating air gaps that act as barriers to sound transmission. Overall, steel channels play a crucial role in sound insulation by providing a solid foundation and structure for sound-absorbing materials and creating a barrier that prevents sound from traveling through the building.

- Q: Can steel channels be used in the construction of mezzanine floors?

- Yes, steel channels can be used in the construction of mezzanine floors. Steel channels provide structural support and stability, making them an ideal choice for mezzanine floor construction. They can be used as beams or joists to support the flooring system and ensure a strong and durable mezzanine structure.

- Q: The top of the elevator shaft is not pre buried hook, and now to add channel, in the channel to do hook, elevator Ii Michihiro 2500, asking the hook bearing 3 tons, the need for large channel, detailed explanation

- To use, use I-beam, after all, span 2500, a little wide, want to save costs on top punching wire rope, anyway, hook is installation or maintenance temporary use, not long-term stress

- Q: What does channel C10 mean? What is the full name of C?

- C steel is different from the channel (such as "C10"), but he also called channel, C10 light is not enough, the leg length, wall thickness, edge are not stereotypes size, must be specifically marked.

- Q: What are the different types of connections for steel channels in modular office systems?

- Steel channels in modular office systems can be connected using various methods to ensure stability and structural integrity. One widely used method is the bolted connection, which involves securing the steel channels together using bolts. These bolts are inserted through pre-drilled holes in the channels and then tightened with nuts. Bolted connections are relatively simple to install and offer a strong and dependable connection. Another option is the welded connection, which involves melting the metal at the connection points and allowing it to solidify, thereby joining the steel channels together. Welded connections are highly durable and provide exceptional strength. However, they require skilled labor and specialized equipment to be properly executed. A third alternative is the riveted connection, where rivets are used to secure the steel channels together. The rivets are inserted through pre-drilled holes in the channels and then deformed to hold them in place. Riveted connections are known for their ability to carry heavy loads and resist vibrations. However, they may be more time-consuming to install compared to bolted connections. Additionally, adhesive connections can also be used. This method involves using high-strength adhesives to bond the steel channels together. Adhesive connections are often used in combination with other connection methods to provide additional stability. They are particularly useful when drilling or welding is not feasible or desirable. To summarize, the available connection options for steel channels in modular office systems include bolted connections, welded connections, riveted connections, and adhesive connections. Each method has its own advantages and considerations, and the choice will depend on factors such as load requirements, installation limitations, and budget constraints.

- Q: Channel 10, 6 meters long, two ends fixed, how much weight can the middle bear?

- It's important to see where you've used it. If you allow it to bend, you'll have to bear a lot of weight, but vice versa

Send your message to us

U CHANNEL JIS U CHANNEL OR GB Q235 Q345B Hot Rolled

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords