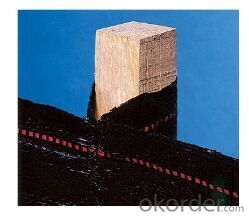

Type 1 Geotextile Fabric Silt Fence with Wooden Stake/Woven Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Weed Barrier Fabric Description:

Weed Barrier Fabric, is a structure composed primarily of geotechnical fabric and that is used as a form of sediment control.These temporary barriers are relatively low in cost, especially when compared to the damages they can prevent. They keep loose soils from traveling into local bodies of water and they also minimize the impact that various forms of development can have on surrounding wildlife.

2.Weed Barrier Fabric Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

9)Fashionable design,high quality,competitive price

10)Long service life

3. Weed Barrier Fabric Usage:

1.Prevent leakage disposal in landfill or waste water or waste dregs disposing field.

2.River bank ,lake dam ,mine remainings ,resevoir ,tunnel ,liquid storage pool(pit ,mine)

3.Preventing leakage in subway ,basement ,tunnel ,hole .

4.Anti-salt leakage in roadbed and other ground sill.

5.The plane direction laying of dam ,the vertical direction laying for ground sill.used in the construction fence and waste material field.

6.Used in ground sill of road ,highway ,railway and waterproof layer of welling clay and wet collapsed loess.

7.Preventing leakage on rooftop.

4. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Can geotextiles be used in athletic field construction?

- Yes, geotextiles can be used in athletic field construction. Geotextiles are commonly utilized in athletic field construction for various purposes such as erosion control, soil stabilization, and drainage management. They can help enhance the durability and performance of the field by preventing soil erosion, improving water drainage, and providing a stable base for the turf or playing surface.

- Q: How do geotextiles help in groundwater protection?

- Geotextiles help in groundwater protection by acting as a barrier that prevents the infiltration of pollutants into the groundwater system. They are used in various applications such as drainage systems, landfills, and erosion control, where they provide filtration and separation of soil particles, ensuring that only clean water enters the groundwater.

- Q: What are the benefits of using geotextiles in construction projects?

- Geotextiles offer several benefits in construction projects. Firstly, they provide excellent soil stabilization, preventing erosion and maintaining the integrity of the structure. Secondly, they enhance drainage and filtration, allowing water to flow through while retaining soil particles. Additionally, geotextiles act as a barrier against weed growth, reducing the need for chemical herbicides. Lastly, they improve the overall lifespan and durability of the construction by reinforcing weak areas and distributing loads evenly.

- Q: 300g / m2 geotextile package is what it means

- 300g / m2 Geotextile: refers to the weight of 300g per square meter (model) 300g / m2 geotextile package: refers to the outsourcing; with 300g of geotextile to wrap something; for example: With 300g / m2 geotextile wrapped gravel. The

- Q: What are the different geotextile testing methods?

- There are several different geotextile testing methods, including but not limited to, grab tensile strength testing, puncture resistance testing, tear resistance testing, burst strength testing, and permeability testing. These methods help assess the physical properties and performance of geotextiles in various applications.

- Q: Where is the geotextile in the municipal works?

- Conservation, consideration, there is more green and more Chinese geotextile material manufacturers

- Q: Related applications, product applications, industrial structure and distribution

- Road cloth, that is, geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile with excellent filtration, drainage, isolation, reinforcement, protection, with a light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance characteristics. The application of geosynthetics originated in the 1950s, the domestic geotextile is one of the national eight five plan, China promulgated in 1998, "geosynthetics staple acupuncture non-woven geotextile" (GB / T -1998) standard, the current geotextile has been widely used in many areas. Geotextile mainly in the following three series: 1, acupuncture non-woven geotextile, specifications 100g / m2-600g / m2 between any choice, the main raw material is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture, Uses are: river, sea, lake embankment slope protection, reclamation, wharf, ship lock flood control and other projects, is through the filter to play a soil and water conservation and effective way to prevent piping. 2, acupuncture non-woven and PE film composite geotextile, specifications have a cloth a film, two cloth a film, the largest width of 4.2 meters The main raw material is to use polyester staple fiber non-woven, PE film through the composite , The main purpose is anti-seepage, apply to railways, highways, tunnels, subways, airports and other projects. 3, non-woven and woven composite geotextile, a variety of non-woven and polypropylene filament woven composite, non-woven and plastic woven composite, suitable for foundation reinforcement, adjust the permeability coefficient of the basic engineering facilities.

- Q: How do geotextiles aid in the reduction of frost heave?

- Geotextiles aid in the reduction of frost heave by providing a barrier between the soil and the freezing temperatures, which helps to prevent the migration of water and the subsequent expansion of ice within the soil. This helps to minimize the upward pressure that causes frost heave, ultimately reducing the potential damage to structures or infrastructure.

- Q: How do geotextiles improve the performance of shorelines?

- Geotextiles improve the performance of shorelines by providing erosion control, stabilizing the soil, and promoting vegetation growth. These synthetic fabrics act as a barrier that prevents soil erosion caused by waves, tides, and currents. Geotextiles also help to distribute hydraulic pressure, reducing the impact of water on shorelines. Additionally, they facilitate the growth of vegetation by retaining moisture and providing a stable base for plant roots, further reinforcing the shoreline and enhancing its overall performance.

- Q: Geotextile puncture test standard

- Staple stitch filament piercing filament woven weaving

Send your message to us

Type 1 Geotextile Fabric Silt Fence with Wooden Stake/Woven Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords