Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

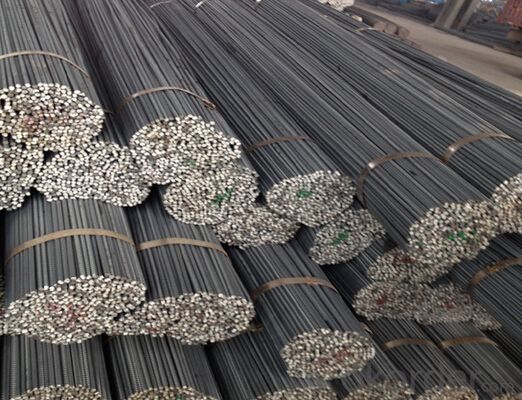

Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

Details of the Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: How do steel rebars affect the constructability of a project?

- Steel rebars play a crucial role in the constructability of a project as they enhance the structural integrity, strength, and durability of concrete structures. By providing tensile strength to concrete, rebars help prevent cracking and ensure the overall stability of the project. Additionally, rebars facilitate the ease of construction by allowing for efficient reinforcement placement and alignment. Overall, steel rebars significantly contribute to the constructability and long-term performance of a project.

- Q: How do steel rebars affect the constructability of projects in environmentally sensitive areas?

- Projects in environmentally sensitive areas can be influenced both positively and negatively by the use of steel rebars. On the positive side, steel rebars are widely utilized in construction due to their strength and durability. They enhance the safety and stability of buildings and infrastructure, which is crucial in areas prone to high wind or seismic activity. By enabling the construction of resilient foundations and reinforcements, steel rebars reduce the risk of environmental damage. Additionally, the sustainability of projects in environmentally sensitive areas can be enhanced through the use of steel rebars. These rebars are highly recyclable, reducing the need for new raw materials and minimizing the environmental impact of resource extraction and processing. Incorporating steel rebars into construction projects can effectively reduce the carbon footprint, aligning with environmental conservation goals. However, there are also negative implications associated with steel rebars in environmentally sensitive areas. The production of steel emits greenhouse gases, contributing to climate change, which can harm fragile ecosystems and vulnerable species. Furthermore, the extraction of iron ore for steel production can lead to habitat destruction and deforestation, further impacting the environment. The transportation of steel rebars to construction sites in environmentally sensitive areas can also present challenges. It often requires the use of heavy machinery and vehicles, which if not properly managed, can cause soil compaction and erosion. This disturbance can disrupt natural habitats and affect the water quality of nearby rivers and streams. In conclusion, while steel rebars offer numerous benefits to projects in environmentally sensitive areas, they also present environmental challenges. It is crucial for construction companies and project stakeholders to carefully consider the sourcing, production, and transportation of steel rebars. Exploring alternative construction materials and techniques with lesser impact on the environment, as well as adopting sustainable practices like recycling steel rebars and reducing carbon emissions, can improve the constructability of projects in environmentally sensitive areas while mitigating their potential negative effects on the environment.

- Q: Can steel rebars be used in structures with high carbonation levels in concrete?

- Using steel rebars in structures with high carbonation levels in concrete is not advisable. Carbonation is a chemical reaction that occurs when carbon dioxide reacts with the alkaline components present in concrete. This reaction leads to a decrease in the alkalinity of the concrete, which can result in the dissolution of the protective layer surrounding the steel rebars. Consequently, the steel becomes exposed to corrosion, ultimately weakening the structure over time. To minimize the risk of corrosion, it is recommended to employ alternative materials such as stainless steel rebars in structures with high carbonation levels. Stainless steel rebars exhibit superior resistance to corrosion compared to carbon steel rebars, enabling them to withstand the harsh environment created by elevated carbonation levels in concrete. Furthermore, it is advisable to consider additional corrosion protection measures, including epoxy coating or increased concrete cover thickness, to further enhance the structure's durability and longevity.

- Q: What is the impact of steel rebars on the sustainability of a structure?

- Steel rebars have a significant impact on the sustainability of a structure. They enhance the structural integrity and durability of buildings, improving their longevity and reducing the need for frequent repairs or replacements. The use of steel rebars also allows for the construction of taller and more complex structures, optimizing space utilization and reducing the environmental footprint. Additionally, steel rebars can be recycled, promoting resource efficiency and reducing the demand for new steel production, thereby contributing to the overall sustainability of the structure and the construction industry as a whole.

- Q: Are steel rebars suitable for reinforcement in historical monuments?

- Steel rebars may not be suitable for reinforcement in historical monuments. The use of steel rebars can cause damage to the structural integrity and aesthetics of these monuments. Traditional materials and techniques that are compatible with the existing structure should be considered instead, to ensure the preservation and authenticity of these historical sites.

- Q: Are steel rebars resistant to chemicals?

- Steel rebars are typically resistant to chemicals. Steel is renowned for its strength and durability, enabling it to endure exposure to various chemicals without significant deterioration. However, the level of resistance may vary based on the specific chemical, concentration, and duration of exposure. Generally, steel rebars exhibit high resistance to commonly found construction materials and environments, including water, concrete additives, and standard cleaning agents. They also withstand acids, alkalis, and organic solvents. Nevertheless, aggressive chemicals like strong acids or oxidizing agents can lead to corrosion or damage over time. Therefore, it is crucial to consider the chemical environment when choosing and utilizing steel rebars, and implement appropriate safeguards if necessary, such as protective coatings or corrosion inhibitors.

- Q: How do steel rebars affect the shrinkage and creep behavior of concrete?

- The shrinkage and creep behavior of concrete are significantly impacted by steel rebars. Shrinkage occurs when concrete contracts as it dries and hardens, while creep refers to the long-term deformation of concrete under sustained load. The presence of steel rebars in concrete has two main effects on its overall shrinkage. Firstly, the rebars provide resistance against shrinkage by countering the tensile forces that arise during drying. This resistance limits the volume change of the concrete, minimizing shrinkage. Secondly, the rebars act as a barrier to moisture movement, thus restricting the drying and shrinkage of the concrete. Nevertheless, the addition of steel rebars can also influence the creep behavior of the concrete. Creep is influenced by the material's modulus of elasticity and strength, both of which can be altered by the presence of steel rebars. The high modulus of elasticity and strength of the rebars can lead to higher levels of creep in the concrete, as there can be differential deformation between the concrete and the steel. Furthermore, the bond between the rebars and the concrete also affects the creep behavior. The strength of this bond influences the transfer of stress from the concrete to the rebars, thereby impacting the overall creep behavior of the composite material. In conclusion, steel rebars can reduce concrete shrinkage by providing resistance against drying and limiting moisture movement. However, they can also influence the creep behavior of the concrete due to factors such as modulus of elasticity, strength, and bond strength between the rebars and the concrete. Understanding the interaction between steel rebars and concrete is essential for designing structures that can withstand shrinkage and creep effects.

- Q: What is the role of steel rebars in preventing structural collapse?

- The role of steel rebars in preventing structural collapse is to provide reinforcement and strength to concrete structures. By being embedded within the concrete, rebars help distribute and withstand tensile forces, enhancing the overall structural integrity and preventing potential failures or collapses that could occur due to excessive loads or external factors.

- Q: What are the guidelines for the proper anchoring of steel rebars in walls?

- The proper anchoring of steel rebars in walls is crucial to ensure the structural integrity and stability of the construction. Here are some guidelines to follow for the correct anchoring of steel rebars in walls: 1. Determine the required rebar size and spacing: The size and spacing of rebars depend on the design specifications and load requirements. Consult the structural engineer or refer to the building codes for the appropriate rebar size and spacing. 2. Clean and prepare the concrete surfaces: Before anchoring the rebars, ensure that the concrete surfaces are clean, free from dust, debris, and any loose material. Use a wire brush or compressed air to remove any contaminants. 3. Use proper anchoring techniques: The most common method for anchoring steel rebars in walls is by embedding them into the concrete. Ensure that the rebars are securely embedded by following these steps: a. Drill holes: Drill holes in the concrete wall at the specified locations and depths, ensuring that the diameter of the hole matches the rebar size. b. Clean the drilled holes: Remove any dust or debris from the drilled holes using compressed air or a brush. c. Insert rebars: Insert the rebars into the drilled holes, making sure they reach the required embedment depth. d. Proper spacing: Maintain the specified spacing between rebars based on the design requirements. e. Secure rebars: Use appropriate anchoring materials like epoxy resin or grout to secure the rebars in place. Follow the manufacturer's instructions for mixing and applying the anchoring material. f. Ensure proper alignment: Verify that the rebars are correctly aligned, both horizontally and vertically, before the anchoring material sets. 4. Allow sufficient curing time: After anchoring the rebars, allow sufficient time for the anchoring material to cure. This ensures that the rebars are firmly secured in place. 5. Properly protect the rebars: Once the rebars are anchored, protect them from corrosion by applying a suitable corrosion-resistant coating or using corrosion-resistant rebars. It is essential to follow these guidelines, as improper anchoring of steel rebars can compromise the structural integrity of the walls and pose safety risks. Always consult with a qualified structural engineer or building professional for specific guidelines tailored to your project.

- Q: What are the advantages of using epoxy-coated stainless steel rebars?

- There are several advantages of using epoxy-coated stainless steel rebars. Firstly, the epoxy coating provides an additional layer of protection to the stainless steel rebars, thereby enhancing their corrosion resistance. Stainless steel already possesses good corrosion resistance properties, but the epoxy coating acts as a barrier against moisture, chemicals, and other corrosive elements that may come in contact with the rebars. This helps to extend the service life of the rebars and ensures the long-term durability of the structure. Secondly, epoxy-coated stainless steel rebars offer improved bond strength with concrete. The epoxy coating creates a rough surface texture, which enhances the adhesion between the rebar and the concrete. This results in a stronger bond, increasing the overall structural integrity of the reinforced concrete. Another advantage is the ease of handling and installation. The epoxy coating provides a smooth surface, making it easier to handle and position the rebars during construction. Additionally, the coating reduces the risk of injury to workers as it eliminates the sharp edges that are typically associated with bare steel rebars. Furthermore, epoxy-coated stainless steel rebars are environmentally friendly. The epoxy coating is free from harmful substances such as lead and other heavy metals, which may be present in alternative coating materials. This makes them a sustainable choice, especially in projects that prioritize environmental considerations. Lastly, epoxy-coated stainless steel rebars require minimal maintenance. The epoxy coating provides a protective layer that reduces the need for frequent inspections and repairs. This not only saves time and costs but also minimizes disruptions to ongoing construction projects. In summary, the advantages of using epoxy-coated stainless steel rebars include enhanced corrosion resistance, improved bond strength, ease of handling and installation, environmental friendliness, and reduced maintenance requirements. These benefits make epoxy-coated stainless steel rebars a reliable and cost-effective choice for reinforcing concrete structures.

Send your message to us

Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords