Steel Reinforcing Bar 5.5mm-32mm for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Reinforcing Bar 5.5mm-32mm for Building

Description for Reinforcing Bar:

| Reinforcing steel bars, rebar, Deformed steel bars | |||

| Size: | 8mm-32mm | Steel Grade: | HRB335, HRB400, HRB500, A615 Gr40, Gr60,BS4449 G460B, G500B JIS SD390, SD490, KS SD40, SD50 |

| Length: | 6m-12m | MOQ each size: | 200MT. |

| Loading port: | Tianjin or any other port china. | Packing: | in bundle. |

Payment term | LC , TT | Application: | Building, bridge , road or project construction |

Data for Reinforcing Bar:

HRB400 | Chemical Composition(%) | C | Mn | Si | P | S |

| 0.25max | 1.60max | 0.80max | 0.045max | 0.045max | ||

Mechanical Property | Yield Strength | Tensile Strenth | Elongation | |||

| 400Mpa min | 540Mpa min | 16% | ||||

HRB500 | Chemical Composition(%)

| C | Mn | Si | P | S |

| 0.25max | 1.60max | 0.80max | 0.045max | 0.045max | ||

| Mechanical Property | Yield Strength | Tensile Strength | Elongation | |||

| 500Mpa min | 630Mpa min | 15% | ||||

| HRB335 | Chemical Composition (%) | C | Mn | Si | P | S |

| 0.25max | 1.60max | 0.80max | 0.045max | 0.040max | ||

Mechanical Property | Yield Strength | Tensile strength | Elongation | |||

| 335Mpa min | 455Mpa min | 17% | ||||

Main Structure for Reinforcing Bar

Standard: AISI, ASTM, BS, DIN, GB, JIS, GOST

Grade: hrb335 hrb400 hrb500

Diameter: 5.5mm-32mm

Length: 6m-12m

Place of Origin: China (Mainland)

Model Number: 5.5mm-32mm

Application: contruction for project and building

steel reinforcing bar size: 5.5mm-32mm

steel reinforcing bar steel grade: hrb400 hrb500 hrb335 hpb300 q195

steel reinforcing bar length: 6mm-12mm

reinforcing bar MOQ:: 300MT for each size

FAQ:

Q: How’s your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

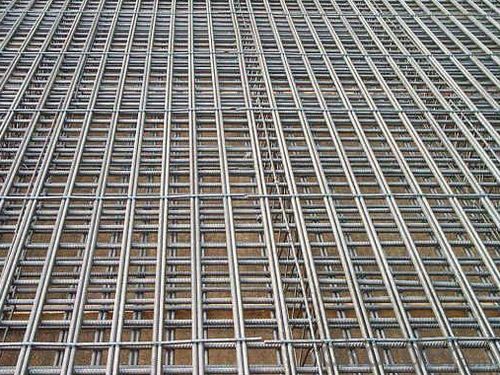

Picture:

- Q: How are steel rebars fixed in concrete slabs?

- Steel rebars are fixed in concrete slabs by being positioned and secured within the concrete mixture before it solidifies. The rebars are typically laid out in a predetermined pattern, and then tied together with wire or secured with metal clips to ensure they stay in place. This reinforcement helps to improve the strength and durability of the concrete slab, making it more resistant to cracking and structural failure.

- Q: Can steel rebars be used in the construction of offshore oil platforms?

- Yes, steel rebars can be used in the construction of offshore oil platforms. Steel rebars are commonly used in construction to reinforce concrete structures and provide additional strength and durability. In the case of offshore oil platforms, steel rebars are used to reinforce the concrete foundations and structures of the platform, helping to withstand the harsh environmental conditions and the weight of the equipment and infrastructure on the platform. The steel rebars are designed to resist corrosion and are typically coated with epoxy or other protective coatings to prevent rusting in the corrosive marine environment. Additionally, steel rebars can be custom-designed to meet the specific requirements of the offshore oil platform, ensuring they provide the necessary strength and stability.

- Q: What are the different types of steel rebars used in road constructions?

- Road constructions commonly utilize various types of steel rebars. These include: 1. Mild steel rebars: These are the most frequently employed rebars in road constructions. They consist of low carbon steel and possess a smooth surface. Mild steel rebars are renowned for their durability and strength, making them suitable for a range of road construction applications. 2. High-strength rebars: Crafted from high-strength steel, these rebars possess a greater yield strength compared to mild steel rebars. They are utilized in road constructions that require enhanced load-bearing capacity, such as bridges and highways. 3. Epoxy-coated rebars: These rebars are coated with epoxy resin to enhance their resistance to corrosion. They are commonly used in road constructions in areas exposed to moisture and chemicals, such as coastal regions. 4. Galvanized rebars: These rebars feature a zinc coating that provides protection against corrosion. They are particularly suitable for road constructions in regions with high humidity or a high risk of corrosion. 5. Stainless steel rebars: Constructed from stainless steel, these rebars exhibit exceptional corrosion resistance. They are frequently employed in road constructions that necessitate long-term durability and resistance to corrosion, such as tunnels and underground structures. Selecting the appropriate type of steel rebar for road constructions is crucial and should be based on specific project requirements, including load-bearing capacity, exposure to corrosion, and environmental conditions. Consulting structural engineers and adhering to local construction codes and standards is essential to ensure the successful implementation of road construction projects.

- Q: How do steel rebars contribute to the crack-resistance of concrete?

- Crucial in improving the crack-resistance of concrete structures are steel rebars, also known as reinforcement bars. These rebars serve as a reinforcement system when embedded within concrete, aiding in the distribution and resistance of tensile forces. This is particularly important due to the relatively low tensile strength of concrete, despite its high compressive strength. The absorption of tensile stresses is the primary means by which rebars contribute to crack-resistance. Without rebars, these stresses would lead to the development of cracks in the concrete. By bearing the tension forces as the load is applied to the structure, the rebars prevent excessive tensile stress and subsequent cracking. This is especially crucial in areas subjected to bending or flexing forces. Additionally, the bond strength between the rebars and the surrounding concrete plays a role in crack-resistance. The presence of rebars improves this bond, preventing the separation or debonding of the concrete under stress. This ensures effective load transfer between the rebars and the concrete, further reducing the likelihood of cracks. Furthermore, steel rebars aid in controlling crack widths in concrete. Acting as a restraint when tensile forces are applied, the rebars limit the width of any cracks that may form. This prevents the cracks from widening and becoming more severe, preserving the overall integrity and durability of the structure. To summarize, steel rebars play a significant role in enhancing the crack-resistance of concrete by absorbing tensile stresses, improving bond strength, and controlling crack widths. Their presence within the concrete structure aids in the distribution and resistance of forces, preventing the formation of cracks and ensuring the longevity and safety of the construction.

- Q: What is the sign of steel rebar

- Standards are the uniform rules for repeating things and concepts. It is based on the comprehensive achievements of science, technology and practical experience, and is approved by the competent authority and issued in a specific form by consensus by the parties concerned, as a criterion and basis for common compliance.

- Q: Can steel rebars be used in architectural detailing?

- Yes, steel rebars can be used in architectural detailing. Steel rebars are often used to reinforce concrete structures and provide additional strength and stability. In architectural detailing, rebars can be incorporated into the design to enhance the structural integrity of the building or to create unique and intricate patterns. Rebars can be bent, shaped, and placed in various configurations to achieve the desired architectural effect. Additionally, steel rebars are durable, resistant to corrosion, and readily available, making them a popular choice in architectural detailing.

- Q: What is the process of threading steel rebars?

- Threading steel rebars involves creating threads on the ends of the rebars to allow for easy and secure connection with other rebars or structural elements. This is typically done using a machine called a rebar threading machine. The first step is to cut the rebars to the desired length and clean the ends to remove any dirt, rust, or debris that could interfere with the threading process. This ensures a smooth and accurate threading operation. Once the rebars are prepared, the rebar threading machine is set up. It consists of a spindle that rotates at a high speed, along with a threading die positioned on the spindle. The threading die has grooves and ridges designed to cut threads into the rebars. To thread a rebar, one end is inserted into the threading machine while the other end is held firmly in place. The machine is then started, and the spindle rotates to cut into the rebar's surface, creating threads by removing small amounts of material. The machine is operated until the desired length of threads is achieved, which can vary depending on project requirements and the type of connection being made. It is crucial to ensure accurate and consistent cutting of the threads to maintain the structural integrity of the rebar connections. After the threading process is complete, the threaded rebars are inspected to ensure clean and defect-free threads that meet the required standards. They are then ready for use in construction projects, where they can be connected to other rebars or structural elements using various methods such as couplers or nuts. In conclusion, threading steel rebars involves cutting and cleaning the rebars, setting up a rebar threading machine, inserting the rebars, and using a threading die to create threads. This process ensures easy and secure connection of rebars in construction projects, providing strength and stability to the structures they are used in.

- Q: Can steel rebars be used in other applications besides construction?

- Indeed, steel rebars can be utilized in applications beyond construction. Although their main purpose is to reinforce concrete structures and provide them with added strength and durability, their properties and characteristics make them suitable for diverse applications. One such application is in the manufacturing of bridges and highways. Steel rebars are commonly employed in the construction of bridge decks and highway pavements, enhancing their load-bearing capacity and resistance to cracking. Another application is in the automotive industry. Steel rebars can be used to manufacture car frames and chassis, improving the structural integrity and safety of vehicles. Furthermore, steel rebars can be utilized in the production of various types of machinery and equipment that require high strength and durability. This can include industrial machinery, agricultural equipment, and even appliances. Additionally, due to their malleability and ability to hold intricate shapes, steel rebars can also be employed in the production of sculptures and artworks. To conclude, although steel rebars are primarily used in construction, their properties enable them to be versatile and applicable in various other industries and contexts.

- Q: What is the role of steel rebars in minimizing cracking due to shrinkage?

- The role of steel rebars in minimizing cracking due to shrinkage is to provide reinforcement and strength to concrete structures. By placing steel rebars within the concrete, they act as a framework that helps distribute the tensile forces caused by shrinkage. This prevents the concrete from cracking and ensures the overall stability and durability of the structure.

- Q: How are steel rebars cut and bent on-site?

- Steel rebars are cut and bent on-site using specialized tools and equipment. The process typically involves the following steps: 1. Measurement: The rebars are measured according to the required length and dimensions specified in the construction plans. This is crucial to ensure accuracy and precision in the bending and cutting process. 2. Cutting: Rebars can be cut using different tools such as manual rebar cutters, hydraulic shears, or portable electric cutters. These tools are designed to provide clean and precise cuts without causing damage to the rebars. The rebars are positioned securely, and the cutting tool is applied to the marked area, resulting in the desired length. 3. Bending: Once the rebars are cut to the required length, they are bent using rebar benders. These machines have various attachments and rollers that can shape the rebars according to the desired angle and radius. The rebars are carefully positioned and secured in the bender, and the machine exerts force to bend them to the specified shape. 4. Quality control: After cutting and bending, the rebars undergo quality control checks to ensure they meet the required specifications. This may involve visual inspections, measurements, and testing to verify the accuracy of the dimensions and the quality of the cuts and bends. It is important to note that skilled workers, such as ironworkers or steel fixers, are typically responsible for the on-site cutting and bending of rebars. They have the expertise to interpret construction plans, use the appropriate tools, and ensure that the rebars are cut and bent accurately to meet the project's needs.

Send your message to us

Steel Reinforcing Bar 5.5mm-32mm for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords