Tower Crane of Chang Li Model Number QTZ40

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 60 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

QTZ40 Description

Feature: Tower Crane

Condition: New

Application: All kinds of costruction

Rated Loading Capacity: 4T

Rated Lifting Moment:500/630/800/1000/1200KN.m

Max. Lifting Load: 4T

Max. Lifting Height: 150m

Span: 42M

Place of Origin: Henan, China (Mainland)

Brand Name: Yu Jie

Model Number: QTZ40

Certification: ISO,CE,BV,SGS

Warranty: 12 months

After-sales Service Provided: Engineers available to service machinery overseas

Tip Load: 0.8

Trolley travel speed: 38/25m/min

Slewing speed: 0.6r/min

Jacking up: 0.4m/min

Powed: 380V/50HZ

Lifting character: 2/4 Fall

QTZ40 Features

1. Export to more than 20 countries with CE/ISO/GOST Certificates.

2. Stationary/Travelling, external/ internal climbing tower crane

3. Impeller blasting/rust protection paint

4. Potain masts designed with dismountable panels, making teansport easier and cheaper.

5. New designed mast, can be used to Internal and external climbing tower crane

6. Famous brand mechanism system, Schneider Electronic control system, jiangte and jiuhe motor

7. Engineers available to service machinery overseas.

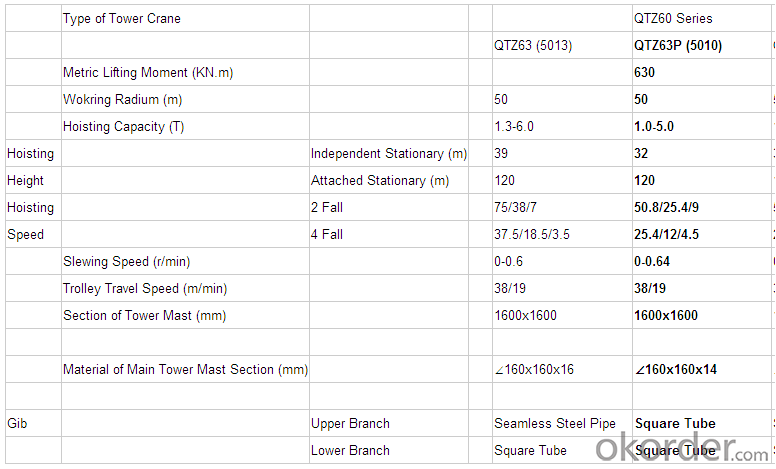

QTZ40 Specification

QTZ40 Pictures

QTZ40 FAQ

Q: What is the principal to quote the right tower crane to the client?

A: First, we need to know clients’ requirements. Normally the following information should be clarified by the client: max lifting capacity, height (height under hook), tip load and jib length.

Q: What can we do for the clients in the market and after-sale service?

A: There is branch office for us in the kingdom and she could provide any commercial assistance for the clients; our exclusive agent would fully represent lifting machinery for business communication and rapid & professional technical support.

Q: What is main advantage for manufacturing construction machinery?

A: Our machinery main advantages mainly include: 1. National-level Research Academy for various building equipment for more than 30 years’ experience; 2. Complete quality control system; 3. Nearly 20 years experiences in manufacturing industries; 4. Over 50 engineers along with 6 local partner companies providing worldwide after-sales service;

- Q: dimentions of crane rail, crane beam.

- What kind of crane? There are thousands of types.

- Q: how can I get rid of what looks like small crane flies in my yard and house. they seem to get in the grass?

- This a common problem. You have a hole in your door and a hidden stink in your house. Another way to get rid of them is you buy a bug spray, turn it on, then leave the house for 1-3 hours.

- Q: What do you do after you made 1000 paper cranes. I know you string them up, but storing them is hard. Do you ceremoniously burn them or what? When can they be gone? This is the missing link in the story I want to know. I have 846 and I want to know what to do after I'm done.

- The okorder /

- Q: would someone who study both white crane kung-fu & ninjutsu be called a mixed martial artist?

- My strictly Kung Fu favorites are Fearless, Ip Man, Ip Man 2. Kung Fu Hustle and Four Dragons come in very, very close behind. Ong Bak 2 showcased some Kung Fu, but wasn't strictly. If it counts, it'd rate with Kung Fu Hustle and Four Dragons, but wouldn't make my top three.

- Q: would 2 500 ton crawler cranes be able to lift a 854 ton bridge section 80 feet in the air?

- Sorry, okorder /... The farther from the center of rotation of the House, the less a crane can lift. That same crane can only lift 57.5 tons at 22 meters from the center of rotation of the House. Ben

- Q: I need the answer badly

- The world would be a little less beautiful. The blue crane's role as a predator in its ecosystem would be left empty, allowing its former prey to breed without check until (hopefully) another predator moves in to pick up the slack. Otherwise the ecosystem will be out of balance.

- Q: I've been making lots of paper cranes lately, thinking I would know exactly what to do with them. In reality, I'm a bit short on ideas... Can you help me with this, because I'd love to find ways to decorate my room with them. I can't really use nails on my walls or ceiling, so I can't do a mobile or randomly string them about.

- Okay - so if you can't string them from the ceiling - than what I would do is buy some round vases/globes, from Pier one or some place like that, and fill them with paper cranes, then set the bowls on your shelves/windowsill/desk/table or other flat surface. I've enclosed some examples below. You can also make a mobile by hanging something like a super strength hook with adhesive. 3M makes them (the same folks who created scotch tape). The adhesive does not damage walls and you can stick them to anything. They can bear up to 30 pounds of weight. Put a few on your ceiling or walls and hang your mobiles from them.

- Q: sun/rising/etcBQ: how often are your winnings

- i'm very bad at those machines..... be it the crane or any other kind, i just failed it again and again (kind of reminded me of squidward's failure to beat spongebob) well, i never had the talent to be the crane..... always failed even at getting the animals, it's so hard to pick them up! oh well~~ scorpio sun and rising

- Q: Today, a crane collapsed on the Grand Mosque in Mecca, killing 87 people. Is God punishing Muslims for 9/11?

- welllllllll, it seems the karma bus just made a stop in Mecca. If it was the work of God..............87 for nearly 3,000. ? C'mon God........put some effort into it. I don't think HE was really trying hard enough.

- Q: Hi there!I was planning on making an electromagnetic crane, and I already understand how the electromagnet works. Its for the science fair in two weeks, but they asked us to make our projects soon.But I not sure hot to build the crane itself, any ideas?

- Woodworking okorder

Send your message to us

Tower Crane of Chang Li Model Number QTZ40

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 60 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords