Top Cross Rail Clip Designed to Click into Rail at Specific Centres Ceiling Grid Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

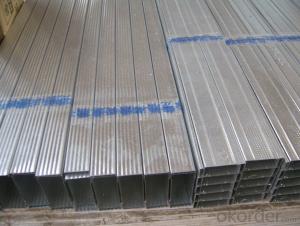

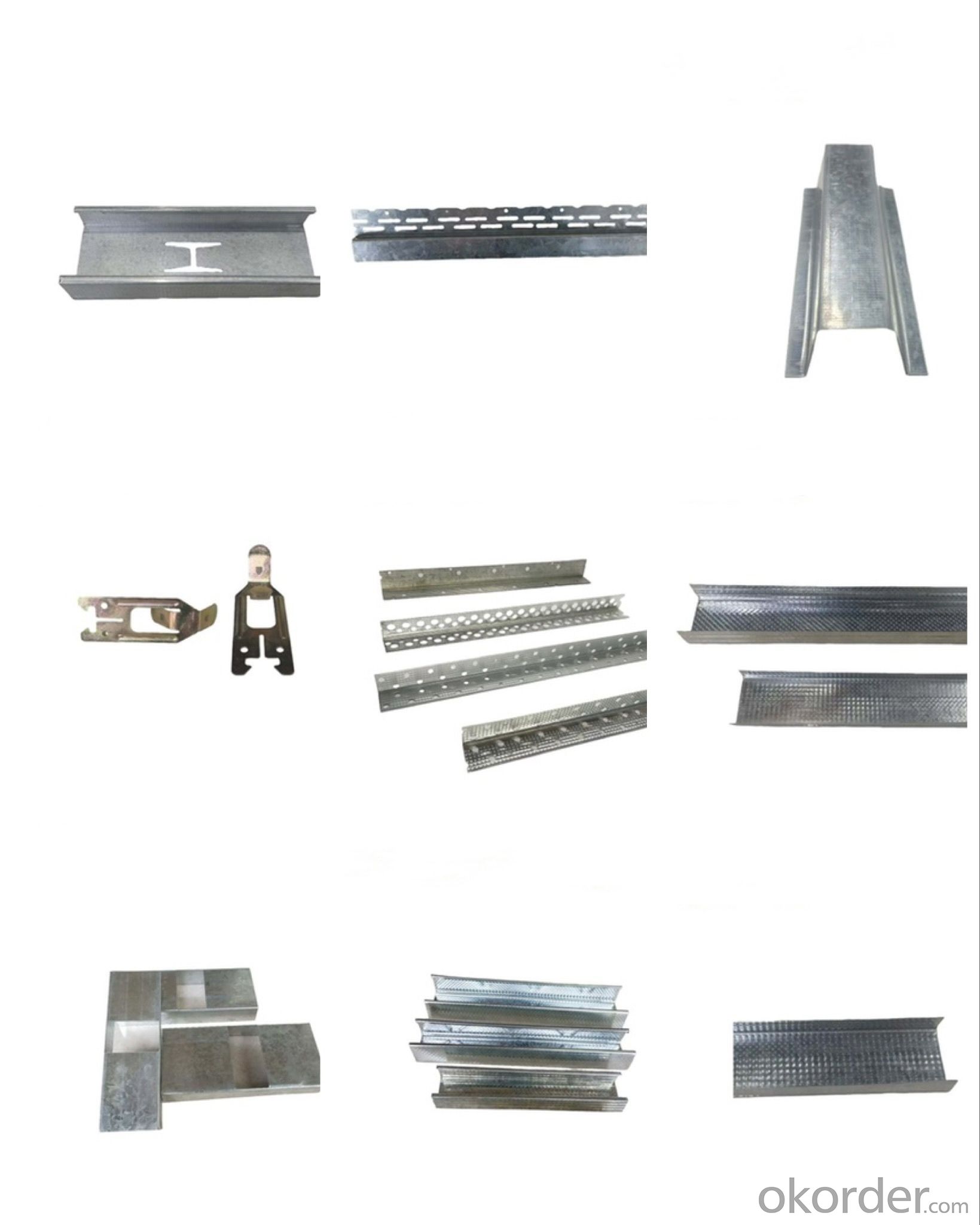

Galvanized suspended metal profile is made of hot galvanized steel, including Ceiling Channel, Metal Carrier, Omega Furring Channel, Wall Angle & fitting accessories. Galvanized ceiling channel has light weight, high strength, fire resistance and noise reduction features. It can be installed with gypsum plasterboard, calcium silicate boards, and other decorative materials.ItemCeiling Steel Profile.

company introduction

a professional metal mesh manufacturer with many years of experience, is a company specializing in the production, sales and service of metal mesh, corner guard, block steel mesh and other construction-related products. Our state-of-the-art manufacturing equipment, skilled workers, high-tech automated production technology and strict quality control ensure that we can quickly produce the most cost-effective qualified products for all our customers. With deep expertise and extensive experience, our engineering and sales teams are happy to help and advise you on finding the best solution for your project. With our advanced technology and in-house production, we can constantly upgrade our products and flexibly respond to changing customer needs.

Product description

Product Name Light skeel keel

Material Galvanized Stee

Feature L/C/U/0MEGA

Package Tape

Advantage Favorable price, lightweight

Zinc 30g-275g

Installation Convenient

Size Customer's Requirment

Product packing

Container size

20GP 5.8*2.25*2.32M

40GP 11.8*2.25*2.32M

40HC 11.8*2.25*2.62M

Standard weight of container:28T(Under normal circumstances)

When the galvanized steel in the container reaches close to the specified weight, it can be loaded into other products with large volume and light weight, such as insulation materials.

FAQ

Q:What is your advantage?

A:We are manufacturer,our company has realized 70% mechanical automation, greatly reduce labors cost. We signed long term contract

with several raw materials factory, guarantee lower price & good quality.

Q: How long is your production time ?

A:10-25 working days after receiving deposit.

Q:What is the shipping way?

A:By sea to your nearest seaport.

Q:Can you product according to the sample?

A:Yes,we can produce according to customers samples or technical drawings. Products can be customized.

Q:Do you provide samples for free?

A:We can provide samples for free, but you need to pay for DHL express cost.

- Q: Light steel keel ceiling calculation method

- Per square meter ceiling need: The main keel 1 meter, deputy keel 2 meters, stays up the keel 2 meters, while the keel for the ceiling around the total length (with the room size, shape). If you want to calculate in detail, it is necessary to see how the layout of the keel on the drawings. for example: The main keel spacing of 1.2 meters, along the length of the layout of the room; vice keel spacing 0.6 m; stays keel spacing 0.6 m; room length 6 m, width 4.5 m. The main keel is: 4.5 ÷ 1.2-1 = 2.75 (root), rounding requires three main keels, keel spacing adjusted to 4.5 ÷ (3 +1) = 1.125 meters. The main keel needs: 6 × 3 = 18 meters. Vice keel is: 6 ÷ 0.6-1 = 9 (root), keel spacing just to meet the design requirements of 0.6 meters. Vice keel need: 4.5 × 9 = 40.5 meters. Hold the keel is: 4.5 ÷ 0.6-1 = 6.5 (root), rounding requires 7 stays keel, keel spacing adjusted to 4.5 ÷ (7 +1) = 0.56 m. Hold the keel need to: 6 × 7 = 42 meters. Side keel need: (6 + 4.5) × 2 = 21 meters. In the material plan, each should also be added to the loss of 1 to 3% OK!

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The effect of the two ceiling is the same, but the material is different, light steel keel price is relatively cheap, the best light steel keel material with accessories per square price of not more than 15 yuan, detailed specifications, the unit price is as follows: 1.0 main keel each Square 2 5,0.5 pairs of keel 8 per square, boom diameter 8MM 1 2, accessories 2 per square, loss plus a little on the line This ratio is limited to flat top, and only to the building materials market, light steel keel store to have such a price Oh, the decoration company fucking offer to turn several times, not just a little bit high, be careful slaughtered. Gypsum board made of the dragon card is good, imported brands are Lafarge, Jieke, can be resistant, more than 20 dollars a count down every square as long as 10 less than How can it be professional? The The

- Q: Tectonic hierarchy of light steel keel

- Main machine The main equipment includes: saws, toothless saws, nail guns, hand saws, hand plane, pliers, screwdrivers, moving, square feet, steel ruler, steel level and so on.

- Q: Tectonic levels and practices of light steel keel

- First find the ceiling of the horizontal line, and then installed in the roof on the big expansion screws. Under the boom, the distance from the boom do not exceed 80mm installation hook, and then on the 38 keel hanging with the installation of the vice keel we generally do 40mm grid, gypsum board specifications are 120mm / 3000mm. Gypsum board installation to stay, 5mm gap. Then there is adhesive powder leveling. And then stick to the bandage, in the putty putty, brush paint.

- Q: Light steel keel gypsum board ceiling is good, or sauna board, integrated ceiling buckle board good?

- Half with gypsum board can now use light steel keel gypsum board ceiling more

- Q: How to pick the ceiling keel

- The keel is an indispensable part of the decoration ceiling, which includes wood keel and light steel keel. Use wood keel to pay attention to the wood must be dry. Now most of the home decoration is not easy to deformation, with fire performance of light steel keel, selection should pay attention to the thickness of the keel, preferably not less than 0.6 mm ceiling metal keel is generally made of light steel and aluminum alloy, with light weight , Rigidity, fire and seismic performance is good, easy to install and so on, according to profile section points, there are U-keel and T-keel.

- Q: Light steel keel is a flat ceiling or integrated ceiling?

- Light steel keel skeleton is widely used in the decoration of the ceiling can use light steel keel skeleton But in order to facilitate the construction, often the ceiling keel will be used to other materials or the use of other materials and light steel keel construction

- Q: For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Ceiling of the keel spacing is too small to easily affect the ceiling of the sound effects and life. Keel skeleton is commonly used in the ceiling of the material, if the early construction of non-standard will seriously affect the aesthetic effect, and may even affect the safety of occupants. The spacing of the keel in the ceiling is very important. The spacing of the keel is different for different ceiling materials.

- Q: Light steel keel ceilings are the main keel specifications is how much

- There are two kinds of galvanized galvanized, one is hot galvanized, one is cold galvanized. Hot galvanized prices are high and cold galvanized prices are low. The ceiling keel consists of the keel (main keel), the cover keel (auxiliary keel) and various accessories. D38 (UC38), D50 (UC50) and D60 (UC60) three series. D38 for hanging point spacing 900-1200 mm not on the ceiling, D50 for hanging point spacing 900-1200 mm Master ceiling, D60 for hanging point spacing 1500 mm Master heavier ceiling, U50, U60 for the cover keel, it With the use of keel. The wall keel consists of horizontal keel, vertical keel and cross brace and various accessories. There are four series of Q50 (C50), Q75 (C75), Q100 (C100) and Q150 (C150) The width of the light steel keel is often used to refer to the keel model, such as the width of 50mm keel is called the 50 keel. Light steel keel side of the high known as the keel side of the high. Keel length is divided into 3 meters, 4 meters two. Keel each price between 12-20 yuan. Paper gypsum board per standard 2400 mm × 1200 mm) price between 22-30 yuan. Plus auxiliary materials costs and labor costs, the general light steel keel partition wall decoration price between 90 to 150 yuan per square meter. There are T line, C-shaped, U-shaped keel and so on.

- Q: Play light steel keel cut off how not to damage the ceiling

- If the existing ceiling is gypsum board, there must be keel in the top

Send your message to us

Top Cross Rail Clip Designed to Click into Rail at Specific Centres Ceiling Grid Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products