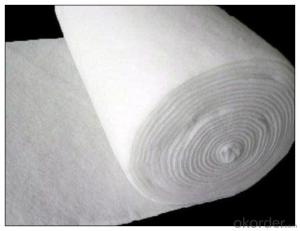

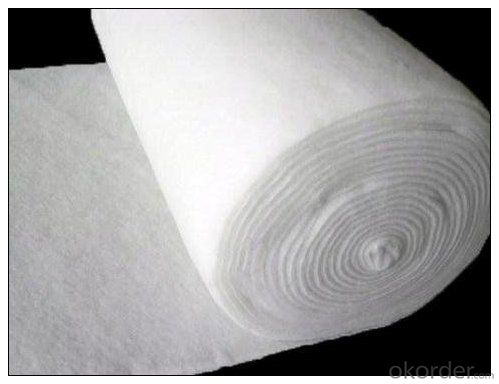

Tissu Géotextile Aiguille Percée Non Tissé Polypropylène

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

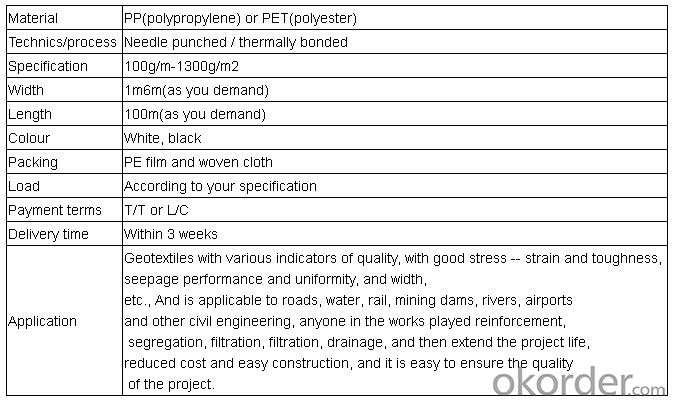

Specifications of Polypropylene geotextiles for River Construction:

1, Biggest Width: 6meter

2, Weight: about 1000gsm

3, Treatment: UV protect

Application of Polypropylene geotextiles for River Construction:

A: Subsurface drainage

B: Roadway separation

C: Hard armor underlayment

D:Asphalt overlay applications

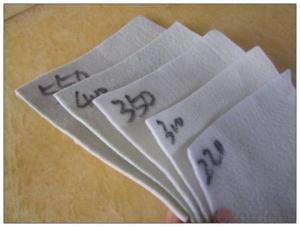

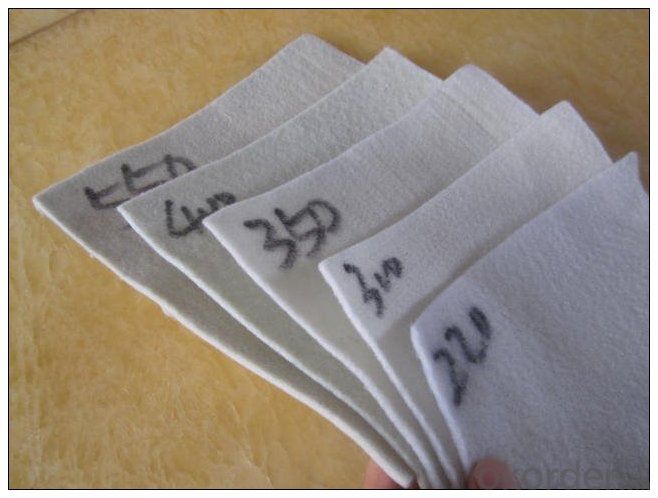

Specification of Polypropylene geotextiles for River Construction:

Functions and Features Polypropylene geotextiles for River Construction:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

9)Fashionable design,high quality,competitive price

10)Long service life

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing reinforcement and stability. They help to prevent soil erosion by acting as a barrier against water flow and sediment movement. Additionally, geotextiles assist in distributing the load evenly across the slope, reducing the risk of structural failure.

- Q: Are geotextiles resistant to fire damage?

- Yes, geotextiles can be resistant to fire damage. Many geotextiles are specifically designed to have fire-resistant properties, which help prevent them from igniting or spreading flames. However, it is important to note that the level of fire resistance may vary depending on the specific type and composition of the geotextile.

- Q: What are the key factors affecting the puncture resistance of geotextiles?

- The key factors affecting the puncture resistance of geotextiles include the thickness and density of the fabric, the type and strength of the fibers used, the presence of any surface coating or treatment, and the overall construction and quality of the geotextile. Additionally, the puncture resistance can also be influenced by environmental factors such as temperature, moisture, and exposure to chemicals or UV radiation.

- Q: What are the factors affecting the performance of geotextiles?

- There are several factors that can affect the performance of geotextiles. These include the type and quality of the material used, the installation and design of the geotextile system, the environmental conditions, such as temperature and moisture levels, and the duration and intensity of the load or stress applied to the geotextile. Additionally, factors such as chemical exposure, UV radiation, and biological activity can also impact the performance of geotextiles.

- Q: What are the different methods of installing geotextiles?

- There are several methods of installing geotextiles, including trench installation, direct placement, and mechanical installation. Trench installation involves excavating a trench and placing the geotextile in the trench before backfilling. Direct placement involves laying the geotextile directly on the ground surface and securing it with stakes or other means. Mechanical installation utilizes specialized equipment, such as a geotextile installation machine, to roll out and secure the geotextile in place.

- Q: Geotextile (250g / square meter) offer

- 250 grams of short fiber geotextile Price: 2.30 yuan / square meter 250 grams of filament geotextile Price: 3.70 yuan / square meter 250 grams of impervious geotextile Price: 2.80 yuan / square meter.

- Q: Can geotextiles be used in shoreline stabilization projects?

- Yes, geotextiles can be used in shoreline stabilization projects. Geotextiles are often used to control erosion, prevent soil displacement, and provide stability to shorelines by acting as a barrier against water flow and wave action. They can help to reinforce the soil and provide long-term protection to shorelines, making them a valuable tool in shoreline stabilization projects.

- Q: What are the considerations for geotextile selection in riverbank stabilization?

- When selecting geotextiles for riverbank stabilization, several considerations need to be taken into account. The first is the strength and durability of the geotextile, as it needs to withstand the erosive forces of the river and maintain its integrity over time. Additionally, the permeability of the geotextile is important, as it should allow for adequate water drainage while preventing the loss of fine soil particles. The installation requirements and methods should also be considered, as some geotextiles may require specialized equipment or techniques. Lastly, the cost-effectiveness of the geotextile should be evaluated, weighing the initial investment against the long-term benefits and effectiveness in stabilizing the riverbank.

- Q: How to calculate the volume weight of polypropylene nonwoven geotextile

- I professional production geotextile geomembrane and other materials, wish smooth

- Q: Geotextile construction inspection batch ye do?

- Plastic woven category: the same formula, the same specifications of 100,000 square meters of products for a group; less than 100,000 square meters, the actual number of a batch. Non-woven geotextiles: the same frequency of production of the same specifications for a number of products; batch volume can be accumulated 100 volumes for a group, but the week is still less than 100 volumes of output, then with a group of output. Plastic woven cloth: batch as a unit, each batch of products randomly take 3 volumes as a sample geotextile categories: each batch of products randomly selected 2% to 3%, but not less than 2 volumes. Sample requirements: the whole width, length 3m or more, the sample can be rolled up, but can not be folded.

Send your message to us

Tissu Géotextile Aiguille Percée Non Tissé Polypropylène

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords