Tinplate of First Class Level for Making Sea food cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate of First Class Level for Making Liquid food cans

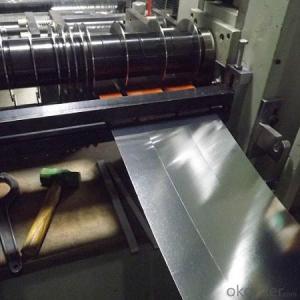

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Specifications

| Type | MR, SPCC |

| Temper(BA&CA) | T1-T5, DR8-DR10 |

| Coating | 1.1-8.4g/m^2 |

| Thickness& Tolerance | 0.15-0.5mm(tolerance +/-0.01mm) |

| Width& Tolerance | 600-1010mm(tolerance +2/-0mm) |

| I.D | 508mm |

| Coil weight | 3-10MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface finish | Bright, stone |

| Package | Seaworthy Export Standard Wooden Pallet |

| Standard | ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202 |

| Special specifications are available on customers' requirements | |

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Chemicals and painting cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans,

- Sea food cans

- Crown corks, easy open ends

- Electrical machinery parts

- Bakeware and household kitchen parts

FAQ

CNBM Branch Offices

In order to promote the business connection, CNBM has established branches and offices in lots of foreign countries, such as USA, GERMANY, UAE, SAUDI ARABIA, IRAN, JORDAN, LIBIA,ETHIOPIA, INDONESA, INDIA,VIETNAM,RUSSIA,KAZAKHSTAN. It is very helpful for the communication and after- sale services.

Factory Introduction

CNBM as one of the largest suppliers in tinplate industry, offers clientss prime quality tinplate in both coil and sheets. With multi-plants and fully integraded production, the annual capacity of tinplate is 400,000MT.

To ensure the high quality if the tinplate, CNBM owns complete equipment series.

- Reversing cold rolling machines: 14 sets

- Continuous rolling machines: 2 sets

- BA furnaces: 50

- CA line: 1

- Tinplate production line: 2

- SA& DA reduced tinplate sheet: Available

CNBM also produce other steel products, such as cold-rolled steel, hot dip galvanized steel, color coated steel and tin free steel coils and sheets.

- Q: How does tinplate perform in terms of heat resistance?

- Tinplate has relatively low heat resistance compared to other metals. It can withstand moderate temperatures without warping or melting, but prolonged exposure to high heat can cause it to lose its shape or even melt.

- Q: How is tinplate affected by different types of cosmetics?

- Tinplate can be affected by different types of cosmetics due to their chemical composition. Certain cosmetics, such as those containing acidic or alkaline ingredients, can cause corrosion or discoloration on the tinplate surface. Additionally, prolonged exposure to certain cosmetics, especially those containing solvents or oils, can lead to the degradation of the protective coating on the tinplate, making it more susceptible to rusting. Therefore, it is important to choose cosmetics that are compatible with tinplate packaging to ensure its longevity and integrity.

- Q: Can tinplate be customized with different designs or logos?

- Yes, tinplate can be customized with different designs or logos. It is a versatile material that can be decorated using various printing techniques such as lithography, offset printing, or embossing. This allows for the creation of unique and personalized designs on tinplate, making it suitable for branding and promotional purposes.

- Q: What are the environmental impacts of tinplate production?

- Tinplate production has several environmental impacts. Firstly, the extraction of tin ore can lead to deforestation and habitat destruction. Secondly, the smelting process releases greenhouse gases, contributing to climate change. Additionally, the use of chemicals and energy during manufacturing can result in air and water pollution. Lastly, the disposal of waste materials, such as slag and wastewater, can contaminate nearby ecosystems. Overall, tinplate production has significant environmental consequences that need to be addressed and mitigated.

- Q: Can tinplate be used for automotive components?

- Yes, tinplate can be used for automotive components. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent corrosion resistance and durability. Automotive components such as fuel tanks, exhaust systems, and body panels can be made from tinplate due to its strength, formability, and resistance to rust.

- Q: How is tinplate used in the manufacturing of toys?

- Tinplate is commonly used in the manufacturing of toys as it provides a durable and lightweight material for various components. It is often used for packaging, such as toy boxes or containers, as it can be easily shaped and decorated. Additionally, tinplate can be used for creating toy parts, such as miniature cars or robots, due to its malleability and ability to hold intricate designs. Overall, tinplate enhances the aesthetic appeal and functionality of toys, making them more appealing to consumers.

- Q: What are the main applications of tinplate in the aerospace industry?

- Tinplate is primarily used in the aerospace industry for manufacturing various components, such as fuel tanks, containers, and protective casings. Its corrosion resistance properties make it ideal for safeguarding against moisture and ensuring the longevity of these critical aerospace components. Additionally, tinplate's lightweight nature contributes to the overall weight reduction of aircraft, enhancing fuel efficiency and performance.

- Q: How does tinplate compare to plastic-coated steel in terms of properties and applications?

- Tinplate and plastic-coated steel have different properties and applications. Tinplate is a thin, lightweight steel sheet coated with a layer of tin, which provides excellent corrosion resistance, solderability, and aesthetic appeal. It is commonly used in food and beverage packaging, as well as in the manufacturing of aerosol containers, electronic components, and various consumer products. On the other hand, plastic-coated steel is steel that is coated with a layer of plastic, typically through a process called extrusion. This coating enhances the steel's durability, impact resistance, and chemical resistance, making it suitable for applications that require protection against harsh environments or harsh handling. Plastic-coated steel is often used in construction, automotive, and electrical industries, where strength and corrosion resistance are crucial. In summary, tinplate is preferred for applications that require corrosion resistance, solderability, and a visually appealing finish, such as food packaging. Plastic-coated steel, on the other hand, is more suitable for applications that demand enhanced durability, impact resistance, and chemical resistance, like in construction or automotive industries.

- Q: What are the different coatings used on tinplate?

- There are several different coatings used on tinplate, including tin-free steel (TFS), electrolytic tinplate (ETP), and tin-coated steel (TCS). Each coating provides specific benefits and functionalities to the tinplate, such as corrosion resistance, durability, and improved appearance.

- Q: What are the advantages of using tinplate for automotive components?

- One advantage of using tinplate for automotive components is its high corrosion resistance. Tinplate is coated with a thin layer of tin, which acts as a protective barrier against moisture and oxidation, ensuring the longevity of the components. Additionally, tinplate offers excellent formability, allowing for complex shapes and designs, which is crucial in the automotive industry. Lastly, tinplate is lightweight yet strong, contributing to improved fuel efficiency and overall vehicle performance.

Send your message to us

Tinplate of First Class Level for Making Sea food cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords