Tinplate For Canned Fish Cans, CA/BA, T4 Temper

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

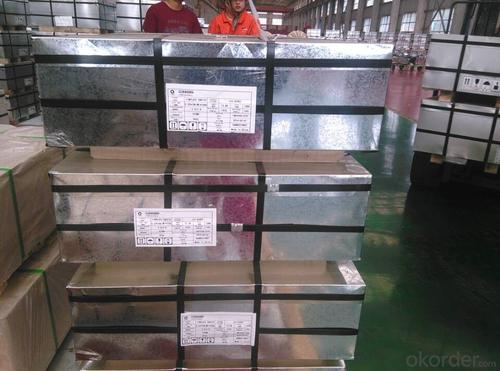

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

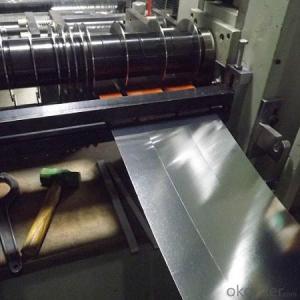

4. Our production steps

5. Usage Scope

6. Our euxport market

our tinplate has been popularly exported to more than 30 countries, including Asia, Europe countries, Gulf area, Sounth America, Northe & South Afric etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: How is tinplate coated with organic materials for specific applications?

- Tinplate can be coated with organic materials for specific applications through a process called organic coating or lacquering. In this process, a thin layer of organic material, such as polymer or lacquer, is applied onto the surface of the tinplate. This coating provides various benefits like corrosion resistance, improved aesthetic appearance, and enhanced durability. The organic coating can be applied through methods like roll coating, spray coating, or electrostatic deposition, depending on the specific requirements of the application.

- Q: Is tinplate resistant to corrosion?

- Yes, tinplate is resistant to corrosion due to its protective tin coating which prevents the steel underneath from coming into contact with moisture or oxygen, thus preventing rusting.

- Q: What are the main applications of tinplate in the chemical industry?

- Tinplate has several main applications in the chemical industry, including the production of cans and containers for storing and transporting chemicals. Its corrosion-resistant properties make it ideal for protecting chemicals from external factors. Tinplate is also used in the manufacturing of chemical equipment, such as pipes and tanks, where its durability and resistance to chemicals are advantageous. Additionally, tinplate can be utilized in the production of chemical packaging materials, labels, and closures, providing a reliable and safe solution for chemical products.

- Q: What are the benefits of using tinplate for electrical components?

- Tinplate offers numerous benefits for electrical components. Firstly, it provides excellent corrosion resistance, ensuring the longevity and durability of the components. Secondly, tinplate has excellent solderability, making it easier to connect and assemble electrical circuits. Additionally, tinplate is a good conductor of electricity, allowing for efficient flow of electrical currents. Lastly, it is a cost-effective option, as tinplate is readily available and relatively inexpensive compared to other materials.

- Q: Can tinplate packaging be used for non-food items?

- Yes, tinplate packaging can be used for non-food items. Tinplate packaging is a versatile and durable material that can be used for various purposes including packaging non-food items such as cosmetics, pharmaceuticals, household products, and more. Its protective properties make it suitable for a wide range of products that require stability, durability, and visual appeal.

- Q: What are the regulations and standards related to tinplate packaging?

- Regulations and standards related to tinplate packaging may vary depending on the specific country or region. However, in general, tinplate packaging is subject to regulations and standards related to food safety, product labeling, and environmental concerns. These regulations ensure that tinplate packaging materials are safe for food contact and that they comply with specific guidelines for packaging materials. Additionally, there may be standards regarding the thickness, coating, and overall quality of tinplate packaging to ensure its durability and performance.

- Q: Can tinplate be used for aerosol packaging?

- Yes, tinplate can be used for aerosol packaging. Tinplate is a common material choice for aerosol cans due to its strength, durability, and resistance to corrosion. It provides a protective barrier against moisture and oxygen, ensuring the integrity of the aerosol product. Additionally, tinplate can be easily formed into various shapes and sizes required for aerosol packaging.

- Q: How does tinplate contribute to the overall aesthetics of packaging?

- Tinplate contributes to the overall aesthetics of packaging through its unique and eye-catching appearance. Its shiny and smooth surface, along with its ability to be printed with vibrant and intricate designs, adds a touch of elegance and sophistication to various products. Additionally, tinplate's durability and versatility allow for the creation of intricate shapes and designs, enhancing the overall visual appeal of packaging.

- Q: How is tinplate cleaned and maintained?

- Tinplate is commonly cleaned and maintained by first wiping it with a soft cloth or sponge soaked in warm soapy water. Any stubborn stains can be gently scrubbed with a non-abrasive cleaner or baking soda paste. After cleaning, it is important to thoroughly dry the tinplate to prevent rusting. To maintain its shine, applying a thin coat of food-grade oil or wax can help protect the tinplate from moisture and oxidation.

- Q: What are the causes of tinplate rusting and how to prevent them?

- Attachment of impurities. The impurity is mainly caused by the difference of the impurity with the iron sheet, or the impurity adsorbed the water on the iron sheet to form a galvanic cell.

Send your message to us

Tinplate For Canned Fish Cans, CA/BA, T4 Temper

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords