Tinplate of First Class Level for Making Liquid food cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

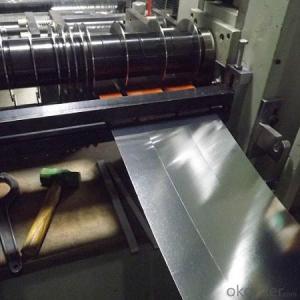

Tinplate of First Class Level for Making Liquid food cans

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Specifications

| Type | MR, SPCC |

| Temper(BA&CA) | T1-T5, DR8-DR10 |

| Coating | 1.1-8.4g/m^2 |

| Thickness& Tolerance | 0.15-0.5mm(tolerance +/-0.01mm) |

| Width& Tolerance | 600-1010mm(tolerance +2/-0mm) |

| I.D | 508mm |

| Coil weight | 3-10MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface finish | Bright, stone |

| Package | Seaworthy Export Standard Wooden Pallet |

| Standard | ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202 |

| Special specifications are available on customers' requirements | |

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Chemicals and painting cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans,

- Sea food cans

- Crown corks, easy open ends

- Electrical machinery parts

- Bakeware and household kitchen parts

FAQ

CNBM International Corporation

CNBM International Corporation, as an important import and export platform of CNBM Group, enjoys competitive advantages in importing and exporting of building materials as well as complete sets of machinery and equipments, engineering, and project contracting.

CNBM Branch Offices

In order to promote the business connection, CNBM has established branches and offices in lots of foreign countries, such as USA, GERMANY, UAE, SAUDI ARABIA, IRAN, JORDAN, LIBIA,ETHIOPIA, INDONESA, INDIA,VIETNAM,RUSSIA,KAZAKHSTAN. It is very helpful for the communication and after- sale services.

Factory Introduction

CNBM as one of the largest suppliers in tinplate industry, offers clientss prime quality tinplate in both coil and sheets. With multi-plants and fully integraded production, the annual capacity of tinplate is 400,000MT.

To ensure the high quality if the tinplate, CNBM owns complete equipment series.

- Reversing cold rolling machines: 14 sets

- Continuous rolling machines: 2 sets

- BA furnaces: 50

- CA line: 1

- Tinplate production line: 2

- SA& DA reduced tinplate sheet: Available

CNBM also produce other steel products, such as cold-rolled steel, hot dip galvanized steel, color coated steel and tin free steel coils and sheets.

- Q: How does tinplate contribute to the resistance of marine equipment?

- Tinplate contributes to the resistance of marine equipment by providing a protective barrier against corrosion. The tin coating on the steel substrate acts as a sacrificial layer that prevents the underlying metal from coming into contact with moisture and saltwater, which are common in marine environments. This corrosion resistance property of tinplate helps to prolong the lifespan of marine equipment and ensures its durability even in harsh conditions.

- Q: What are the main applications of tinplate in the tobacco industry?

- The main applications of tinplate in the tobacco industry include the production of cigarette packaging, such as cigarette boxes and tins. Tinplate offers excellent protection against moisture, light, and air, helping to preserve the quality and freshness of tobacco products. Additionally, tinplate's durability and malleability make it ideal for creating intricate designs and embossing, enhancing the aesthetic appeal of tobacco packaging.

- Q: Can tinplate be used for packaging personal hygiene products?

- Yes, tinplate can be used for packaging personal hygiene products. Tinplate is a commonly used material for packaging due to its durability, corrosion resistance, and ability to preserve the quality and freshness of products. It is commonly used for packaging various personal hygiene items such as soaps, shampoos, lotions, and cosmetics.

- Q: What are the main challenges in tinplate warehousing?

- The main challenges in tinplate warehousing include ensuring proper inventory management, maintaining product quality and integrity, optimizing space utilization, managing complex logistics, and adhering to stringent safety and regulatory requirements.

- Q: How does tinplate contribute to the performance of sports equipment?

- Tinplate contributes to the performance of sports equipment by providing a durable and lightweight material that is resistant to corrosion. It is commonly used in the manufacturing of cans, containers, and protective coatings for sports equipment, ensuring longevity and enhancing performance. Additionally, tinplate offers excellent adhesion properties, allowing for better grip and control, especially in activities that involve handling equipment such as racquets, bats, or golf clubs.

- Q: Can tinplate be used for packaging alcoholic beverages?

- Yes, tinplate can be used for packaging alcoholic beverages. It is a commonly used material in the packaging industry due to its durability, resistance to corrosion, and ability to maintain product freshness. Tinplate cans are often used for packaging beer, wine, and spirits, providing a reliable and protective container for alcoholic beverages.

- Q: Is tinplate suitable for hot or cold food products?

- Tinplate is suitable for both hot and cold food products.

- Q: What are the advantages of using tinplate for construction materials?

- One of the advantages of using tinplate for construction materials is its durability. Tinplate is known for its exceptional strength and resistance to corrosion, making it suitable for various construction applications. Additionally, tinplate is lightweight, which allows for easier handling and installation. Furthermore, tinplate offers excellent aesthetic appeal, as it can be easily painted or decorated to match any desired design. Overall, tinplate's durability, lightweight nature, and aesthetic versatility make it a favorable choice for construction materials.

- Q: How does tinplate affect the overall weight of packaging?

- Tinplate tends to increase the overall weight of packaging due to its heavier density compared to other materials commonly used for packaging.

- Q: How does tinplate packaging contribute to product protection against oxidation?

- Tinplate packaging contributes to product protection against oxidation by providing a barrier between the product and the surrounding environment. Tinplate is made by coating thin sheets of steel with a layer of tin, which acts as a protective barrier against moisture, air, and other external elements that can cause oxidation. This barrier prevents the entry of oxygen, which is necessary for oxidation to occur, thereby extending the shelf life of the product and maintaining its quality and freshness.

Send your message to us

Tinplate of First Class Level for Making Liquid food cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords