Tinplate of First Class Level for Making Dry food cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

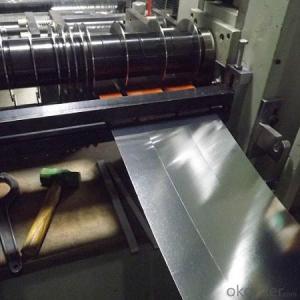

Tinplate of First Class Level for Making Dry food cans

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Specifications

| Type | MR, SPCC |

| Temper(BA&CA) | T1-T5, DR8-DR10 |

| Coating | 1.1-8.4g/m^2 |

| Thickness& Tolerance | 0.15-0.5mm(tolerance +/-0.01mm) |

| Width& Tolerance | 600-1010mm(tolerance +2/-0mm) |

| I.D | 508mm |

| Coil weight | 3-10MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface finish | Bright, stone |

| Package | Seaworthy Export Standard Wooden Pallet |

| Standard | ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202 |

| Special specifications are available on customers' requirements | |

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Chemicals and painting cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans,

- Sea food cans

- Crown corks, easy open ends

- Electrical machinery parts

- Bakeware and household kitchen parts

FAQ

What is CNBM ?

China National Building Materials Group Cooperation, as a leading state-owned enterprise with 3 billion USD and 40,000 staff in China, CNBM was established in 1984 under the administration of the state-owned Assets Supervision and Administration commission of the State Council. There are over 300 surbordinate factories and companies in our group; 2 public listed companies in Hong Kong, 4 Public listed companies in China mainland; 11 publicly listed companies in which CNBM has a substantial percentage of shares. The business scope of CNBM covers from Manufacturing and sales of building materials to scientific research and design, engineering, import and export trading.

CNBM International Corporation

CNBM International Corporation, as an important import and export platform of CNBM Group, enjoys competitive advantages in importing and exporting of building materials as well as complete sets of machinery and equipments, engineering, and project contracting.

CNBM Branch Offices

In order to promote the business connection, CNBM has established branches and offices in lots of foreign countries, such as USA, GERMANY, UAE, SAUDI ARABIA, IRAN, JORDAN, LIBIA,ETHIOPIA, INDONESA, INDIA,VIETNAM,RUSSIA,KAZAKHSTAN. It is very helpful for the communication and after- sale services.

- Q: What are the main applications of tinplate in the paint industry?

- Tinplate is commonly used in the paint industry for packaging purposes. It is primarily used for manufacturing paint cans, which provide a durable and protective container for storing paint products. Tinplate cans also offer excellent resistance to corrosion and airtight sealing, ensuring the longevity and quality of the paint. Additionally, tinplate cans are easy to handle, stack, and transport, making them a convenient choice for the paint industry.

- Q: Can tinplate be used for packaging household cleaning products?

- Yes, tinplate can be used for packaging household cleaning products. It is a durable and versatile material that provides excellent protection and preservation for such products. Additionally, tinplate is resistant to corrosion, making it suitable for storing various cleaning agents safely.

- Q: How does tinplate contribute to the protection of musical instruments?

- Tinplate, with its durable and corrosion-resistant properties, plays a crucial role in protecting musical instruments. By utilizing tin-coated steel, commonly known as tinplate, musical instrument manufacturers can create sturdy and long-lasting instrument cases. These tinplate cases provide a reliable shield against external factors such as impact, moisture, and temperature fluctuations, ensuring the safety and preservation of the delicate musical instruments inside. Additionally, tinplate's resistance to oxidation and rust prevents the formation of harmful contaminants that could potentially damage the instruments. Therefore, tinplate contributes significantly to safeguarding musical instruments, extending their lifespan, and maintaining their optimal condition.

- Q: How does tinplate contribute to the overall convenience of packaging?

- Tinplate contributes to the overall convenience of packaging by providing a durable, lightweight, and easily recyclable material for various consumer goods. Its corrosion resistance properties ensure the longevity and freshness of packaged products, while its versatility allows for different shapes and sizes of packaging. Additionally, tinplate's ability to be easily processed and printed on facilitates branding and labeling, enhancing the convenience and attractiveness of the packaging.

- Q: What are the advantages of using tinplate for packaging?

- There are several advantages of using tinplate for packaging. Firstly, tinplate is highly durable and can withstand external impacts, protecting the contents of the package. Secondly, it is resistant to corrosion, ensuring the longevity of the packaging and preventing contamination of the product. Additionally, tinplate is lightweight and easy to handle, reducing transportation costs and making it convenient for consumers. Moreover, tinplate is environmentally friendly as it is 100% recyclable, promoting sustainability and reducing waste. Lastly, tinplate offers excellent printing capabilities, allowing for attractive designs and branding options, which can enhance product visibility and appeal.

- Q: What are the different printing methods used on tinplate?

- The different printing methods used on tinplate include lithography, offset printing, and silk-screen printing.

- Q: What are the main growth drivers for the tinplate industry?

- The main growth drivers for the tinplate industry are increasing demand for packaged food and beverages, growth in the automotive sector, and rising urbanization.

- Q: How is tinplate used in the packaging industry?

- Tinplate is commonly used in the packaging industry due to its excellent properties such as corrosion resistance, durability, and formability. It is often used in the production of metal cans and containers for food and beverages, cosmetics, and other consumer goods. The tin coating on the steel substrate provides a protective barrier against moisture, light, and oxygen, ensuring the preservation and prolonging the shelf life of the packaged products. Tinplate is also used for decorative purposes, as it can be easily printed on, making it an ideal choice for branding and marketing.

- Q: How does tinplate packaging contribute to product tamper resistance?

- Tinplate packaging contributes to product tamper resistance by providing a strong and durable barrier that is difficult to breach without leaving visible signs of tampering. Its rigid nature and secure sealing mechanisms make it difficult for unauthorized access to the product, ensuring the integrity and safety of the contents. Additionally, tinplate packaging often includes tamper-evident features such as seals, breakable caps, or indicators that clearly show if the package has been opened or tampered with, providing a clear visual cue to the consumer.

- Q: Can tinplate be used for packaging products with sensitive electronic components?

- Yes, tinplate can be used for packaging products with sensitive electronic components. Tinplate is a material that provides excellent protection against moisture, corrosion, and electromagnetic interference. It also offers good electrical conductivity and is commonly used in the packaging of sensitive electronic devices to ensure their safety and integrity during transportation and storage.

Send your message to us

Tinplate of First Class Level for Making Dry food cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords