Tinplate with First- Class Level for Tin Cans Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate with First- Class Level for Tin Cans Making

Tinplate Specification

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has extremely beautiful metalllic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

Tinplate Applications

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

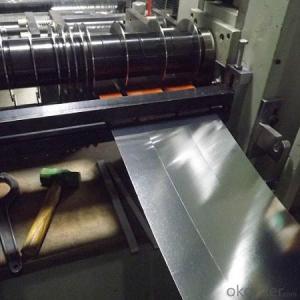

Tinplate Pictures

Tinplate Features

Steel Type: MR, SPCC

Temper(BA& CA): T1- T5, DR8- DR10

Coating: 1.1- 8.4g/m^2

Tickness: 0.15- 0.,50mm

Width: 600-1010mm

I.D: 508mm

Coil weight: 3- 10mt

Passivation: 311

Oiling: DOS

Surface finish: Bright, Stone

Quantity for 20 Feet FCL: 20- 25MT

Package: Seaworthy Export Standard Wooden Pallet

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products

Chemicals and painting cans

Dry food ccans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends

Electrical machinery parts

Bakeware and household kitchen parts

Production Standard

GB/T 2520-2000

JIS G3303-2002

DIN EN 10202-2001

ASTM A623M-2002

ISO 11949-1995

- Q: Can tinplate be used for packaging tobacco products?

- Yes, tinplate can be used for packaging tobacco products. Tinplate is a commonly used material for packaging due to its durability, resistance to corrosion, and ability to preserve the quality of the tobacco. It also provides a convenient and attractive packaging solution for consumers.

- Q: How is tinplate affected by different types of dairy products?

- Tinplate, a type of steel coated with a thin layer of tin, can be affected by different types of dairy products in terms of corrosion. Dairy products, particularly those with high acidity or salt content, can cause the tin coating to corrode over time. This can result in changes in the taste, odor, and quality of the dairy products stored in tinplate containers. Therefore, proper packaging and storage conditions need to be ensured to maintain the integrity of tinplate when storing dairy products.

- Q: What are the common packaging formats for tinplate?

- The common packaging formats for tinplate include cans, containers, tins, and boxes.

- Q: What are the different ways to open tinplate containers?

- There are several ways to open tinplate containers, including using a can opener, a pair of scissors, a knife, or pulling the tab if it is a pop-top can.

- Q: Are there any health concerns associated with tinplate?

- Yes, there are some health concerns associated with tinplate. Tinplate can potentially leach small amounts of tin into the food or beverage stored in it, especially if it comes into contact with acidic or high-salt content products. While tin is considered relatively safe, excessive consumption of tin can lead to gastrointestinal issues and long-term exposure may have adverse effects on health. It is recommended to limit the use of tinplate for storing or consuming highly acidic or salty foods.

- Q: Is to buy canned tinplate or aluminum

- Tinplate, our company sells tinplate

- Q: How does tinplate perform in terms of recyclability?

- Tinplate is highly recyclable and has one of the highest recycling rates among packaging materials. It can be recycled indefinitely without losing its properties, making it an environmentally friendly choice.

- Q: Can tinplate be used for microwave-safe packaging?

- No, tinplate cannot be used for microwave-safe packaging as it is a metal material that can cause sparks and potential hazards in the microwave.

- Q: How does tinplate packaging contribute to brand recognition?

- Tinplate packaging contributes to brand recognition by providing a visually appealing and distinctive packaging solution. The use of tinplate materials allows for unique and eye-catching designs, logos, and branding elements to be printed directly on the packaging. This helps in creating a strong visual identity and making the brand stand out on the retail shelves. Additionally, tinplate packaging is often associated with a premium and high-quality image, which can further enhance brand recognition and consumer perception.

- Q: How does tinplate compare to other packaging materials?

- Tinplate is highly versatile and durable, making it an excellent choice for packaging materials. It offers superior protection against moisture, oxygen, and light, ensuring the freshness and quality of the packaged products. Additionally, tinplate is eco-friendly as it is 100% recyclable, making it a sustainable choice. Its strength and resistance to corrosion further enhance its appeal compared to other packaging materials.

Send your message to us

Tinplate with First- Class Level for Tin Cans Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords