Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price Description

| Steel Type | MR | ||

| Temper(BA&CA) | T1~T5, DR8, DR9 | ||

| Coating | 1.1~11.2g/m2 (Both Equal and Differential) | ||

| Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) | ||

| Width & tolerance | 300~1000mm (Tolerance: 0~3mm) | ||

| Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) | ||

| Coil inside diameter | 420/508mm | ||

| Coil Weight | 3~10 MT | ||

| Passivation | 311 | ||

| Oiling | DOS | ||

| Surface Finish | Bright, Stone, Silver, Matte | ||

| Packaging | Seaworthy Standard with wooden pallet | ||

| Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 | ||

| Special specitications are available on request. | |||

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price China

Tinplate can ensure food hygiene and minimize the possibility of corruption, effectively

prevent the danger to health, but also in line with modern convenience in tinplate packaging

of canned food diet, rapid demand, tea packaging, coffee packaging, health careproduct

packaging, candy wrappers, cigarette packaging, gift packaging, food packaging containers

are preferred.As well as other miscellaneous cans of the oils and fats cans, chemicals

cans, beverage cans, spray cans, and and so on on.

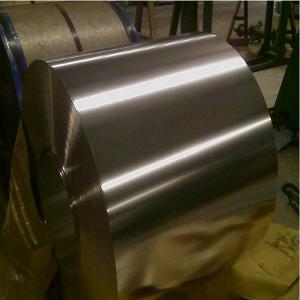

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price Images

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price Specification

FAQ of Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price

How long does it take to get the product if i place an order?

With the process of your requirements,we will pack and deliver in 3-7 days.If it is by sea shipment,it will take 15-45 days depending on different locations.

- Q: Can tinplate packaging be used for toy products?

- Yes, tinplate packaging can be used for toy products. Tinplate packaging is often chosen for its durability and ability to protect products during transportation and storage. It can also be customized with attractive designs, making it a suitable option for toy packaging.

- Q: Why do tin tins rust easily when they are opened?

- It turned out to be sealed and oxygen has been transpiring. When opening is oxidized (Fe2o3), there is rust.

- Q: How does tinplate contribute to the protection of textile products?

- Tinplate contributes to the protection of textile products by providing a durable and corrosion-resistant packaging material. It acts as a barrier against moisture, oxygen, and light, preventing the deterioration of textile products during storage and transportation. Tinplate's protective properties help maintain the quality, color, and integrity of textiles, ensuring they reach consumers in optimal condition.

- Q: How is the thickness of tinplate measured?

- The thickness of tinplate is typically measured using a specialized instrument called a micrometer. This handheld device allows for precise measurement of the tinplate thickness by exerting pressure on the surface and providing an accurate reading in millimeters or inches.

- Q: What are the different printing techniques used on tinplate?

- There are several different printing techniques used on tinplate, including lithography, screen printing, and offset printing. Lithography involves creating an image on a flat surface, such as a metal plate, and then transferring that image onto the tinplate. Screen printing involves using a mesh screen to apply ink onto the tinplate in a desired pattern or design. Offset printing involves transferring an image from a plate onto a rubber blanket, and then onto the tinplate. Each technique has its own advantages and is chosen based on factors such as cost, complexity of the design, and desired quality of the print.

- Q: Can tinplate be used for packaging heavy products?

- Yes, tinplate can be used for packaging heavy products. Tinplate is a strong and durable material that can withstand the weight of heavy items, making it suitable for packaging purposes. Its resistance to corrosion and ability to protect the contents from external factors further enhance its usefulness for packaging heavy products.

- Q: How does tinplate handle exposure to gases and odors?

- Tinplate is highly resistant to gases and odors, making it an excellent material for packaging and storing sensitive products. It forms a protective barrier that prevents any unwanted smells or gases from penetrating the container, ensuring the integrity and quality of the contents inside.

- Q: 0.25mm which melting point is low in tin plate and tin plate?

- Zinc plating on the surface of thin steel plates and steel strips by continuous hot dip plating prevents corrosion of the surface of thin steel plates and steel strips. Galvanized steel sheet and steel strip are widely used in machinery, light industry, construction, transportation, chemical industry, post and telecommunications and other industries

- Q: Does tinplate corrode over time?

- Yes, tinplate can corrode over time due to exposure to moisture, oxygen, and other corrosive elements. However, the corrosion rate of tinplate is relatively slow compared to other metals, thanks to the protective layer of tin that covers the steel base. Regular maintenance and proper storage conditions can help slow down the corrosion process.

- Q: What are the main regulations governing the use of tinplate in different industries?

- The main regulations governing the use of tinplate in different industries vary depending on the country or region. However, some common regulations include health and safety standards, environmental regulations, and product labeling requirements. These regulations aim to ensure the safe and responsible use of tinplate in industries such as food packaging, automotive, construction, and electronics.

Send your message to us

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords